11

Stitching Process

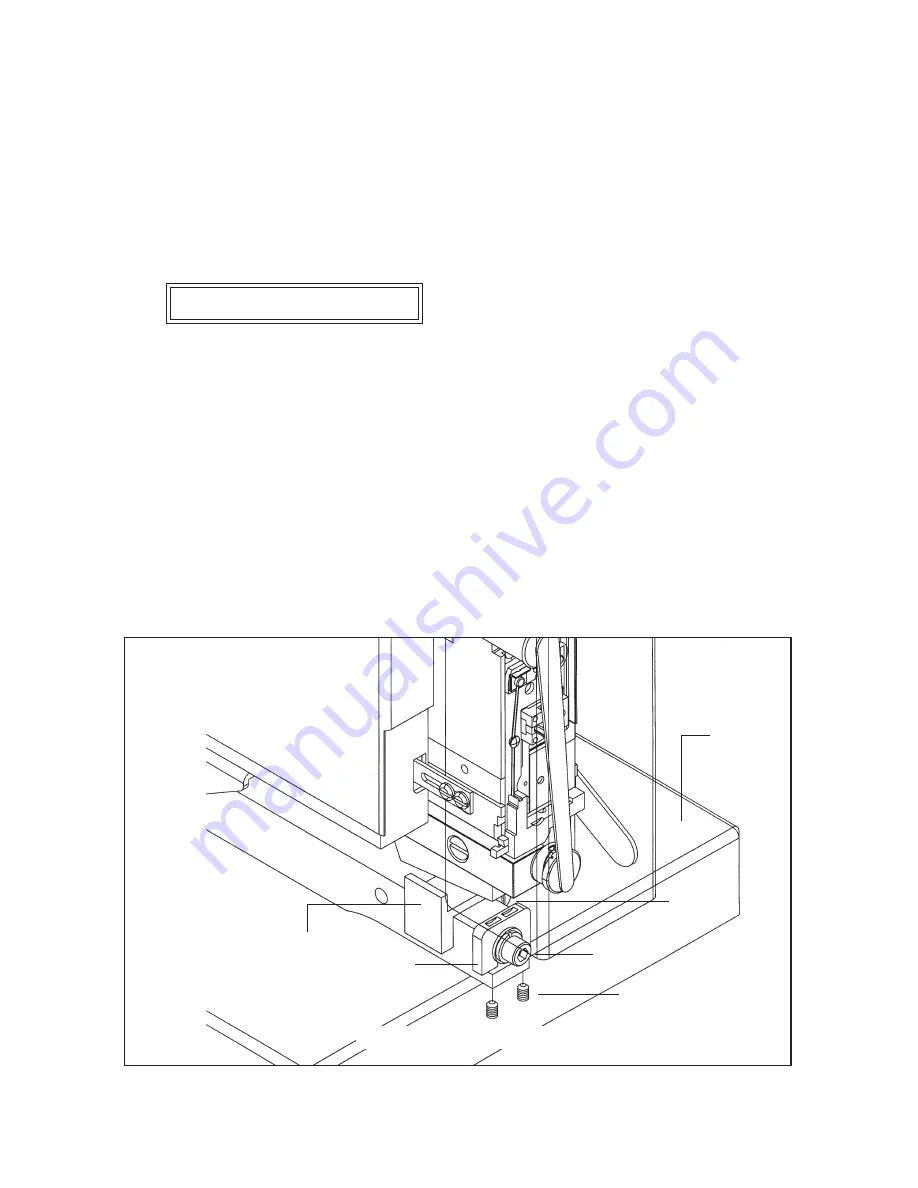

The MiniStitcher has been specifically designed to use a solid Clincher Plate. For this reason,

adjustable work tables and table trips have not been installed on the MiniStitcher. Following is a brief

explanation of options available for the machine.

The Solid Clincher (MG10178) is attached to the Platform Weldment (MG10170A) on every

MiniStitcher. Because the Clincher is mounted to a stationary Clincher Arm, the legs of each stitch

are bent when the wire is pushed through the stock and hits the Clincher as opposed to the Clincher

Points on moveable Clincher Plates coming up to meet the wire. Having fewer moving parts

supporting this process results in a more solid brace for the stitches as they are driven into the stock,

a more sustained capacity and fewer wear parts to replace.

Minor adjustments can be made to the Solid Clincher if necessary. Loosen the Screw (UA4808.3)

retaining the Solid Clincher on the Clincher Arm to adjust the Clincher side to side.

The Back Stop (MG10176) attaches to the Clincher Arm with a Thumb Screw (P2731) and is used

to consistently locate the depth of the stitch.

Solid Clinching (Figure 6)

Figure 6 - Solid Clinching

MG10170A

UA2804.6 (2)

MG10076

MG10178

UA4808.3

P2731

Summary of Contents for IMSHP-A25

Page 2: ...0...

Page 28: ...26 The MiniStitcher...

Page 29: ...27...

Page 54: ...52 NOTES...

Page 55: ...53...