Unit Preparation

12

SECTION III - Unit Preparation

Handling Instructions

The PERFORMANCE is generally easier to

handle and maneuver once removed from the

shipping carton and pallet.

To remove the shipping carton and pallet:

a. Remove the shipping straps and open

the top of the carton to remove the

wood shipment insert.

b. Lift the carton over the unit to remove.

If ceiling height is limited, the carton

maybe cut open using care not to dam-

age the exterior jacket of the unit.

c. Remove the front burner hood to pre-

vent damage prior to lifting the unit

from the shipping pallet.

When lifting or moving the unit do not

use the burner or its components as a

means of a handle. Hand-truck the unit

from the rear only.

d.

Discard all packing materials.

Hydrostatic Pressure Test

Prior to permanently connecting water,

gas supply or electrical supply, perform

a pressure hydrostatic test of the outer

tank to ensure all piping connections

were not damaged during shipment.

Hydrostatic Test Preparation

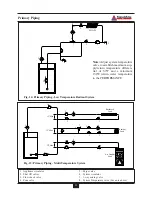

1. Mount the circulator on the supply pipe as

shown in Figure 11 page 23.

2. Temporarily plug the primary return con-

nections as shown in Figure 11 using a 1”

NPT pipe plug. Use pipe dope sparingly to

allow removal of the plugs upon comple-

tion of the test.

3. On the outlet flange of the circulator pipe

install a 1” NPT nipple and shut-off valve.

Use pipe dope sparingly to allow removal

of the fittings upon completion of the test.

To avoid getting water onto the unit

and/or surrounding area, additional pip-

ing from the shut-off to a catch bucket or

drain may be required.

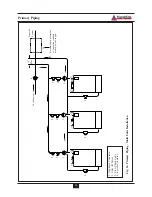

4. Connect a hose to the primary circuit drain

valve located per Figure 45 page 70, Item 2

and connect the other end to a fresh water

supply. Ensure the hose can be used as a

drain hose upon completion of the test.

Hydrostatic Test Procedures

1. Open the shut-off valve installed on the

outlet flange of the circulator.

2. Open the fresh water supply valve and then

open slowly the primary circuit drain valve

to fill the outer tank with water.

3. When the water within the outer tank

reaches the shut-off on the primary supply,

close the primary circuit drain valve.

4. Close the shut-off valve, on the top of the

circulator.

5. Slowly reopen the primary circuit drain

valve until the test pressure on the temper-

ature / pressure gauge reaches

10 psig

maximum

. Close the primary circuit drain

valve and fresh water supply valve.

To prevent damage to the inner tank the

test pressure must not exceed 10 psig.

6. Allow the test pressure to remain for 10

minutes.

CAUTION

NOTICE

BEST PRACTICES

WARNING