20

Primary Piping

SECTION V - Primary Piping

General Piping Requirements

Low Water Cutoff Device

-

The PERFORMANCE is equipped with a

factory installed pressure switch style

Low Water Cut Off device.

-

The minimum operating system pressure

allowable with this device is 10 psig.

-

Check local codes which require a low

water cutoff device for compliance of

this device.

Backflow Preventer

-

Use a backflow preventer valve in the

make-up water supply to the unit as

required by local codes.

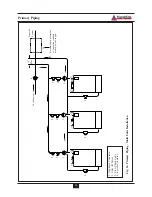

Primary System Piping Applications

All piping applications shown in this instal-

lation manual utilize a primary/ secondary

piping arrangement. This method is rec-

ommended as a means to provide priority

to the production of domestic hot water.

For other piping arrangements, consult the

Engineering Department at Triangle Tube

or consult other approved/recognized

design arrangements.

On piping applications utilizing a single

zone or other recognized piping design

arrangements, it is recommended the

installer uses flow/check valves with

weighted seats at or near the appliance to

prevent gravity circulation.

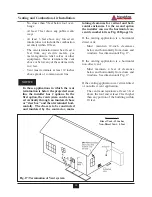

To prevent potential outer tank failure,

the primary system piping must be a

“closed” loop sytem to avoid any oxygen

contamination of the boiler water.

Expansion Tank and Makeup Water

Ensure the expansion tank is properly sized

for the outer tank volume (20 gallons) and

the system volume and temperature.

Undersized expansion tanks will cause sys-

tem water to be lost through the pressure

relief valve and cause additional makeup

water to be added to the system. Eventual

primary tank failure can result due to this

excessive makeup water addition.

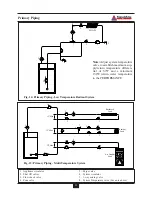

The expansion tank must be located as

shown in Figure 11, 11A or 11B page 23 or

as per recognized design methods. Refer to

the expansion tank manufacturer instruc-

tions for additional installation details.

Connect the expansion tank to an air sepa-

rator only if the air separator is located on

the suction side (inlet) of the system circu-

lator. Always locate and install the system

fill connection at the same location as the

expansion tank connection to the system.

Diaphragm (Bladder) Expansion Tank

Always install an automatic air vent on the

top of the air separator to remove residual

air from the system.

Closed-Type (Standard) Expansion Tank

It is recommended to pitch any horizontal

piping toward the expansion tank 1 inch per

5 feet of piping. Use 3/4” piping for the

expansion tank to allow air within the sys-

tem to rise.

CAUTION

NOTICE

BEST PRACTICE

BEST PRACTICE