16

Domestic Piping

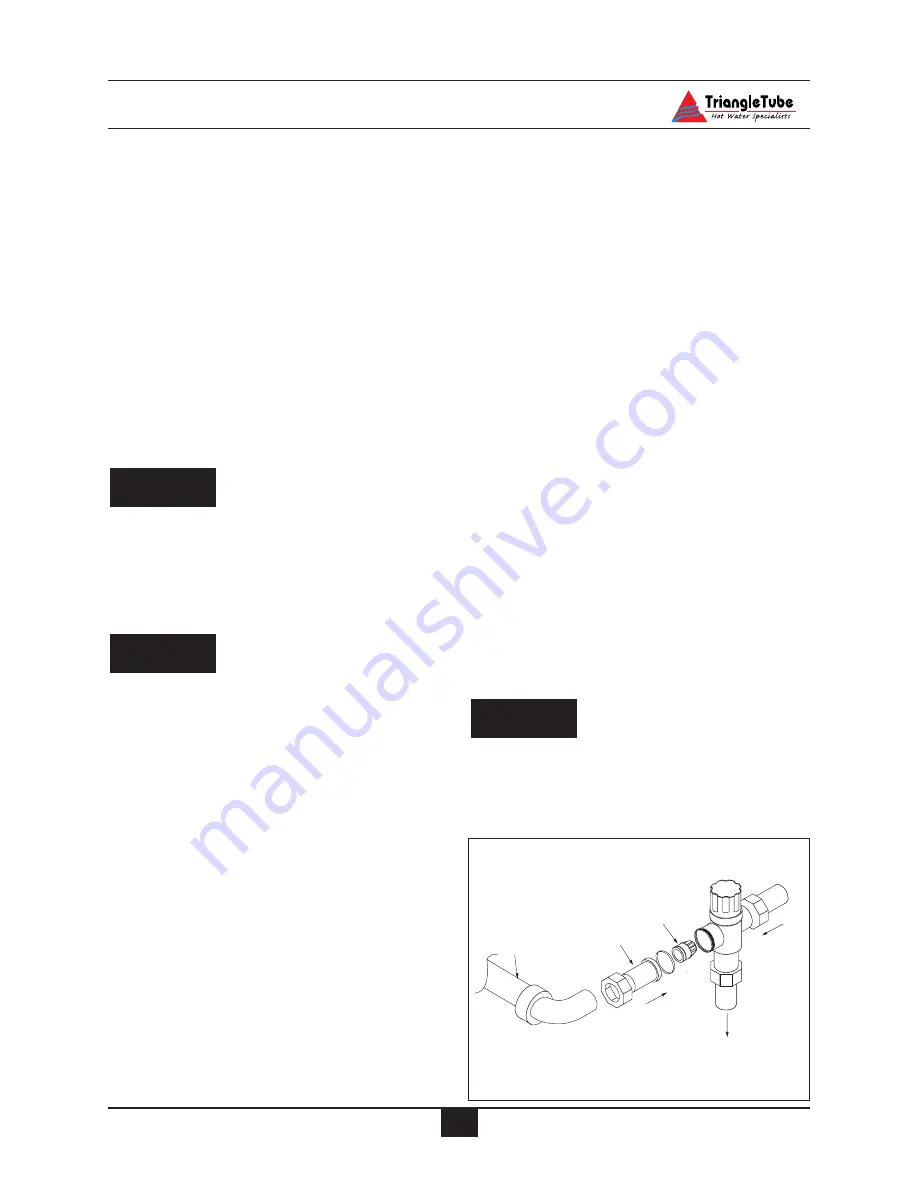

3. Solder the U-Tube Assembly onto the

adapter. (See Fig. 5)

4. Once the adapter has sufficiently

cooled, re-insert the check valve assem-

bly making sure of orientation and

reconnect onto the mixing valve.

If the installation of the PERFORMANCE

requires domestic hot water for a commer-

cial dishwasher, the installer may insert a

tee connection between the unit and the

mixing valve to provide 140ºF domestic

hot water. The installer must reference

local plumbing codes to ensure if this type

of application is permissible.

The thermostatic mixing valve MUST be

installed and utilized on the PERFOR-

MANCE. Removal of the thermostatic

mixing valve will result in severe person-

al injury or death.

The manual valve on the U-Tube assem-

bly must remain in the full open position

for proper operation of the thermostatic

mixing valve.

Domestic Drain Valve

-

The installer must install a drain valve

and drain leg as shown in Fig. 6 page 17

or Fig. 7 page 18.

-

The drain valve should be positioned

close to the floor to aid in the siphon

action required to drain the inner tank.

Multiple Units Installation

For applications using multiple units the

domestic piping should be piped using a bal-

anced manifold arrangement.

The installer should remove the thermostatic

mixing valve from the units and install a single

thermostatic mixing valve at the outlet of the

hot water manifold. The thermostatic mixing

valve should be sized according to the required

flow rate and pressure drop. Refer to the ther-

mostat mixing valve manufacturer specifica-

tion and installation instructions for more

details.

Reference Fig. 8, page 18 for piping diagram.

Storage Tank Application

For applications requiring large volumes of

domestic hot water in a relative short period,

the installer may include a storage type tank

(see Fig. 9 page 19) in the domestic piping.

The installer must:

1. Relocate the thermostatic mixing valve

from the PERFORMANCE to the out-

let of the storage tank.

2. Provide recirculation from the storage

tank back to the PERFORMANCE

using a bronze type circulator.

Maximum recommended flow rate is 5

to 10 gpm.

This can be accomplished through the

drain connection if a 3rd tapping is

unavailable and the circulator should be

controlled by an aquastat.

NOTE

CAUTION

DANGER

Cold

Hot

U-Tube Assembly

Adapter

Check Valve

Mixed

Fig. 5: Mixing Valve Assembly