BECT832-SSO Screwdriver Controller

Operation Manual

DELTA REGIS

Tools Inc.

www.deltaregis.com

Page 14

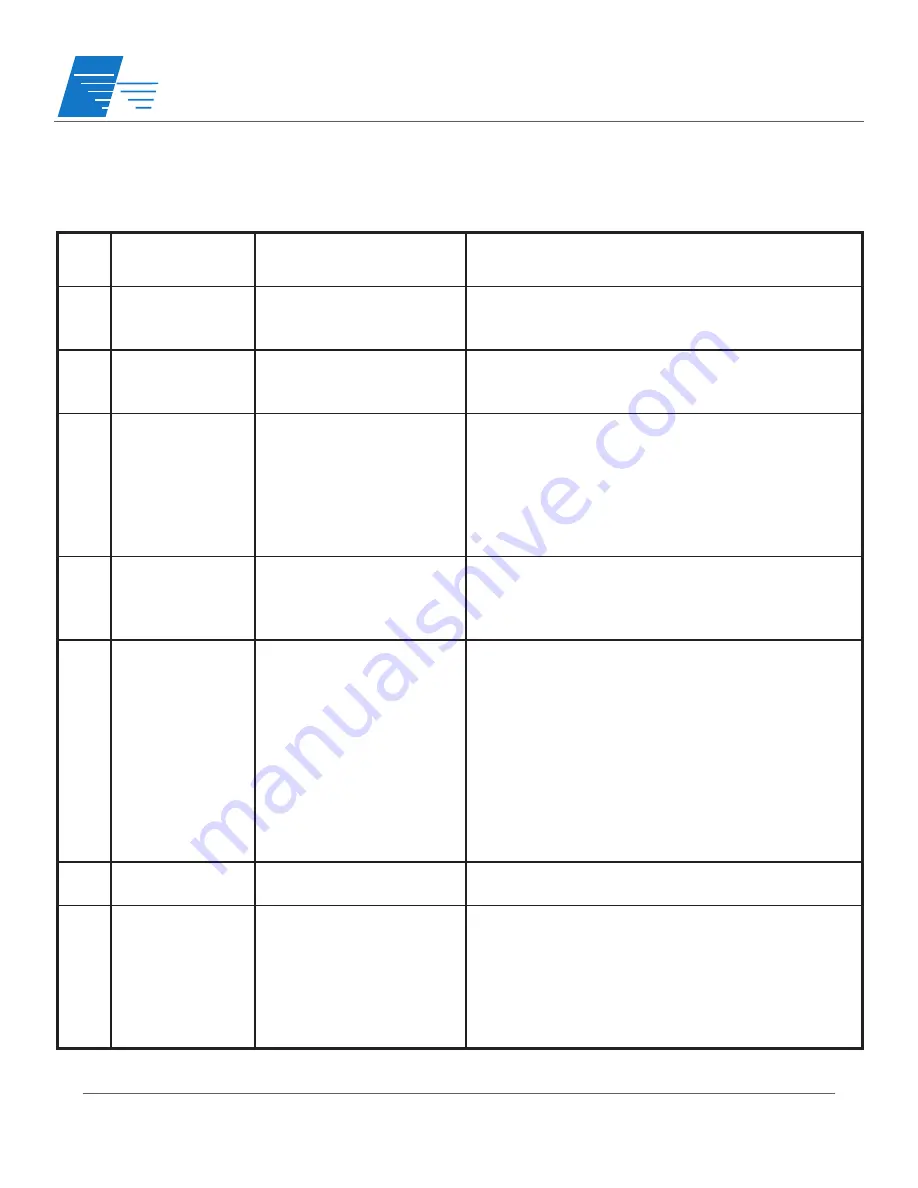

During operation of the counting controller and screwdriver, the LED display may indicate an error code.

These codes indicate a fault that was encountered during the operation of the tool/controller.

Code Indicates

Error Description

Possible Cause / Solution

E3

Low Voltage

Protection

Screwdriver has stopped

because the operating

voltage is too low.

- tool supply voltage has dropped below acceptable

levels due to excessive current draw or malfunction.

If problem persists, send in for evaluation.

E4

High Temperature

Protection

Screwdriver has stopped

because the operating

temperature is too high.

- excessive duty cycle; allow tool/controller to cool

down and re-test at lower duty cycle

- internal issue; send for evaluation/service

E5

Stall Protection

Screwdriver has stopped

because the motor stalled

abnormally.

- prevailing torque (eg. soft joint, thread cutting)

is causing the tool’s motor to slow down and stall

before reaching final torque; evaluate suitability of

tool for the application

- internal damage to gearing, clutch, or lack of

lubrication is affecting motor’s ability to complete the

rundown; inspect gearing and clutch

E7

FWD/REV Switch

Error

Controller detected a

change in the position of

the FWD/REV switch while

the tool was running.

- FWD/REV Button was moved by the operator

during rundown

- switch PCB improperly positioned in tool housing

or magnetic switching element has failed

E8

Brake Error

Controller detected an

abnormal brake (clutch)

signal before the tool was

started.

- clutch is stuck at the top of the clutch ramp,

possibly caused by operator releasing trigger too

early in anticipation of shut-off. Turn off power to the

driver, put a 1/4” hex key in the output shaft and turn

the output shaft to reset the clutch - you will here

a click when it resets. Ensure that operators are

instructed to hold the trigger until the tool clicks over

the clutch and shuts off.

- internal push rod mechanism for clutch shut-

off is sticking or of incorrect length. Send tool for

evaluation/service.

E9

Flash Memory

Error

The internal flash memory

has failed.

- reset the controller to see if the error clears; if error

persists, send in for evaluation and service.

PC

Power Change

An error or change in the

tool supply voltage has

been detected.

- Hi/Lo speed switch position was changed with the

key lock turned ON. Lock must be off to change

speed setting.

- voltage setting incorrect for screwdriver being

used. (eg. 40V setting selected for a 32V driver)

- very soft joint causing power drop during rundown

- faulty tool cable/connection; test with a new cable.