4-106

Service Manual

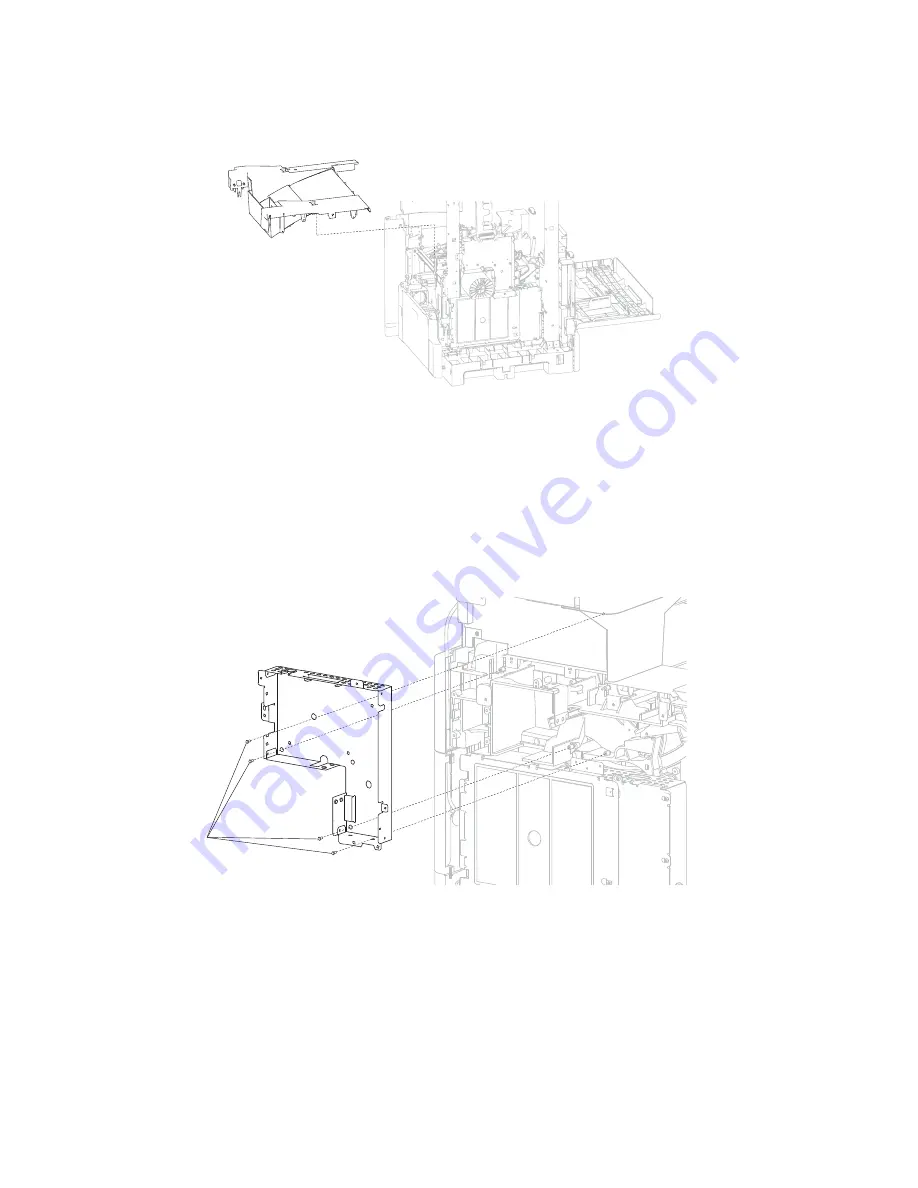

9.

Remove the laser cover.

4.

Remove the four screws (A) from the controller card cage.

5.

Remove the controller card cage.

A

8.

Remove the print cartridge cover. See

“Print cartridge cover assembly removal (model X658)” on

page 4-120

.

3.

Remove the scanner controller card. See

“Scanner controller card assembly removal (models X651,

Laser cover removal (models X651, X652/5535dn, X654, and X656)

2.

Remove the scanner unit assembly. See

“Scanner unit assembly removal (models X651,

X652/5535dn, X654, and X656)” on page 4-94.

X654, and X656)” on page 4-85.

1.

Remove the ADF unit assembly. See

“ADF unit assembly removal (models X651, X652/5535dn,

(model X658)” on page 4-129

.

X652/5535dn, X654, and X656)” on page 4-132

or

“Scanner controller card assembly removal

Summary of Contents for Multifunction Laser Printer 5535dn

Page 1: ... SULO ...

Page 2: ... ...

Page 19: ...Notices and safety information xix ...

Page 20: ...xx Service Manual ...

Page 212: ...2 180 Service Manual ...

Page 258: ...3 46 Service Manual Media tray assembly Wear strips Side guides End guides ...

Page 348: ...4 28 Service Manual 7 Disconnect the connection C from the MPF pick solenoid assembly C ...

Page 433: ...Repair information 4 113 8 Disconnect the cable F from the card reader F ...

Page 436: ...4 116 Service Manual 5 Remove the pins D on both sides securing the links C A B D ...

Page 438: ...4 118 Service Manual 9 Lift the operator panel door assembly out of the machine ...

Page 475: ...Repair information 4 155 4 Remove the LVPS cooling fan ...

Page 476: ...4 156 Service Manual Option removals High capacity input tray ...

Page 479: ...Repair information 4 159 3 Remove the HCIT tray cover front A ...

Page 481: ...Repair information 4 161 2 Remove the HCIT cover rear ...

Page 483: ...Repair information 4 163 4 Remove the HCIT cover right A ...

Page 509: ...Repair information 4 189 2 Remove the tray roller catch assembly from the drawer ...

Page 510: ...4 190 Service Manual 550 sheet option tray assembly ...

Page 516: ...4 196 Service Manual 5 Remove the 550 sheet frame assembly ...

Page 531: ...Repair information 4 211 ...

Page 565: ...Repair information 4 245 ...

Page 572: ...4 252 Service Manual ...

Page 574: ...5 2 Service Manual ...

Page 580: ...7 2 Service Manual Assembly 1 Covers X651 X652 5535dn X654 and X656 ...

Page 584: ...7 6 Service Manual Assembly 3 Covers 2 X658 ...

Page 586: ...7 8 Service Manual Assembly 4 Media path and ducts ...

Page 588: ...7 10 Service Manual Assembly 5 Pick arm and media tray assemblies ...

Page 596: ...7 18 Service Manual Assembly 9 Fuser and LVPS card assemblies ...

Page 598: ...7 20 Service Manual Assembly 10 Flatbed scanner ...

Page 600: ...7 22 Service Manual Assembly 11 ADF unit assembly 1 ...

Page 602: ...7 24 Service Manual Assembly 12 ADF covers ...

Page 604: ...7 26 Service Manual Assembly 13 ADF feed and drive 3 11 7 13 5 9 2 10 6 4 12 8 1 ...

Page 606: ...7 28 Service Manual Assembly 14 ADF electronics ...

Page 608: ...7 30 Service Manual Assembly 15 550 Sheet option tray assembly X658 ...

Page 612: ...7 34 Service Manual X654 and X656 Assembly 17 550 Sheet option tray assembly X651 X652 5535dn ...

Page 616: ...7 38 Service Manual Assembly 19 MFP stapler assembly 1 ...

Page 620: ...7 42 Service Manual Assembly 21 MFP stapler assembly 3 4 5 1 2 3 6 6 7 8 9 10 11 ...

Page 622: ...7 44 Service Manual Assembly 22 MFP stapler assembly 4 1 2 ...

Page 624: ...7 46 Service Manual Assembly 23 MFP offset stacker assembly 1 1 ...

Page 628: ...7 50 Service Manual Assembly 25 MFP Offset stacker 3 4 5 1 2 3 6 6 7 8 9 10 11 ...

Page 630: ...7 52 Service Manual Assembly 26 MFP 4 bin mailbox assembly 1 1 ...

Page 632: ...7 54 Service Manual Assembly 27 MFP 4 bin mailbox assembly 2 3 2 4 5 11 8 9 10 7 1 6 ...

Page 636: ...7 58 Service Manual Assembly 29 Envelope feeder 1 ...

Page 642: ...7 64 Service Manual ...

Page 646: ...I 4 Service Manual ...