Power Cabling, Cords and Connectors

PowerMax systems support single-phase, three-phase Delta and three-phase Wye wiring configurations.

Topics:

•

•

•

•

Best practices: Power configuration guidelines

•

•

•

PowerMax 2000 line cord and jumper configurations

•

PowerMax 8000 line cord and jumper configurations

Power distribution units

CAUTION:

Dell EMC PDUs are designed to be mounted securely in Dell EMC racks. They are not intended for third party

racks.

PowerMax systems are powered by two redundant power distribution units (PDUs), one for each power zone. The PDUs are available in

three wiring configurations:

•

Single-phase

•

Three-phase Delta

•

Three-phase Wye

The AC power cords (single-phase and three-phase) extend above the bay egress for connection to the customer power supply. 15ft

(4.57M) power cords that plug into the bottom of the PDUs are provided. For single-phase, more than one power cord per power zone

may be required.

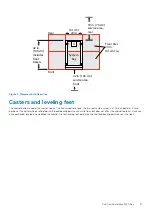

The AC cords can be routed out either the bottom or the top of the rack. If the customer requires power to be supplied from overhead,

Dell EMC recommends replacing the rear top cover of the bay with the ceiling routing top cover, which allows the power cables inside the

machine to be routed out through the top.

A second option is to "drop" the power cables down the hinge side, to the bottom, and route them inside the machine. The cables should

be dressed to allow all doors to open freely and space should be provisioned accordingly to accommodate an adjacent cabinet.

If the customer requires power to be supplied from overhead, the Overhead Routing Kit is available to route the power cables inside the

machine through the top. Extension cables are not provided. See

on page 60 for information on optional kits.

NOTE:

Utilize proper strain relief methods when customer-provided power drops are located overhead or wall-mounted.

Power interface

Data centers must conform to the corresponding specification for arrays installed in North American, International, and Australian sites.

Customers are responsible for meeting all local electrical safety requirements.

Customer input power cabling

Before the array is delivered, the customer must supply and install the required receptacles on their PDUs for zone A and zone B power

for each system bay.

Dell EMC recommends that the customer's electrician be present at installation time to work with the Dell EMC customer engineer to

verify power redundancy.

8

Power Cabling, Cords and Connectors

35