- 25 - 115.6031.0

6)

Connect a source of Chlorine, Sulfur Dioxide or Ammonia gas to the Vaporizer supply piping.

DO NOT use liquid Chlorine, Sulfur Dioxide or Ammonia for leak testing since one volume of

liquid Chlorine expands to roughly 450 volumes of gas.

7)

Leave the first in-line valve closed. Quickly open and close the gas valve on the chemical

container to pressurize the first piping section.

8)

Using a half-filled nozzle bottle, check for leaks by spraying the fumes only of 26° Baume

Aqueous Ammonia (Ammonium Hydroxide), household Ammonia is not strong enough, on all

fittings of Chlorine or Sulfur Dioxide systems. Ammonia systems can be checked for leaks by

using either sulfur tapers or moist litmus test papers. Sulfur tapers, litmus papers, and

instructions for their use are available from the Ammonia supplier.

9)

A Chlorine or Sulfur Dioxide leak will produce a dense white smoke. If a leak appears, open

the isolating valve (the one in-line valve that is closed) and turn on water to the ejector. The

vacuum created will evacuate the gas from the system so that the leak can be corrected

safely. Leaks around valve stems may usually be eliminated by tightening the packing

nut(s). Leaks at non-permanent (flanged or coupling) joints may usually be eliminated

by retightening. Leaks at permanent (threaded) joints can only be eliminated by disassembly

and reassembly.

10) Test the entire piping system in sections by repeating the same procedure. Close the next

in line valve downstream, open the upstream valve. Quickly open and close the gas

valve on the chemical container to pressurize the section and test all fittings with the

appropriate method.

11) Allow the system to remain pressurized overnight after it has been tested to determine if any

additional leaks have developed. Retest all pipe joints. If no new leaks have developed,

evacuate the system using the ejector. Chemical leaks become worse with time as the

chemical attacks the metal at the leak.

3.5

Optional Water Level Control

The water level control pressure switch must be adjusted in the field prior to use. To properly set the level

switch, the water jacket must be at least 155° F as indicated on the temperature controller. The switch

should be set to close the water supply solenoid when the water level reaches the overflow vent connection

on the rear of the water jacket (midpoint on the water level indicator). The indicator switch should be set to

activate the solenoid when the water level drops to the bottom of the water level indicator.

If the purgemeter is provided, set the purgemeter to allow a dripping overflow from the overflow vent

connection with the water jacket at operating temperature.

3.6

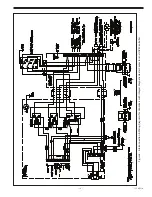

Controller Operation (LOVE Controller)

This section provides fundamental operating procedures for the Evaporator's Temperature Controller

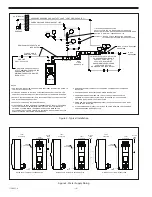

(Controller location on the Vaporizer is shown in Figure 1).

For a more detailed presentation of Temperature Controller operation and features, the Series 16C

Microprocessor Based Temperature Process Control Instruction Manual is provided separately as a reference

only to supplement the information provided in this instruction bulletin.

The 16C Temperature Controller is a full-function controller and has been pre-configured at the factory for

the intended operation of the Vaporizer. The temperature and alarm parameters have been arbitrarily set

and MUST be changed in accordance with the procedure described in the start-up section of this chapter.

Individual process parameter values may be set by stepping through the 16C's setup menus using the

front-panel push-buttons as explained in the next section. The controller's front panel controls and

indicators are shown in Figure 10.

CAUTION

The sequences shown are the default sequences at the time of Vaporizer shipment.

Should the sequences not appear as shown, the program has become

compromised and must be corrected prior to placing the Vaporizer into service.

Summary of Contents for Capital Controls 71V3B Series

Page 1: ... 1 115 6031 0 Instruction Manual Series 71V3B Electrically Heated Vaporizer CAPITAL CONTROLS ...

Page 9: ... 9 115 6031 0 Figure 1 Sectional Diagram ...

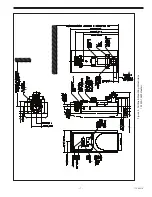

Page 17: ... 17 115 6031 0 Figure 4 Outline Mounting Dimensions 12 kW 15 kW Heaters ...

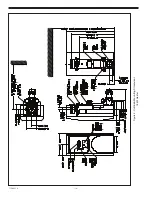

Page 18: ...115 6031 0 18 Figure 5 Outline Mounting Dimensions 18 kW Heater ...