Page 11

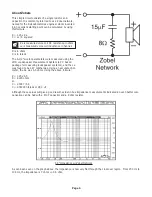

4. Solder all component connections on the p.c. board

using silver or electronics grade (60/40) solder. At this

time, you should also solder the riveted .205 terminal

connections. A properly soldered connection appears

shiny and smooth. We recommend using a soldering

iron with a wattage rating between 20-30watts. Using

wire cutters, trim off all excess component leads.

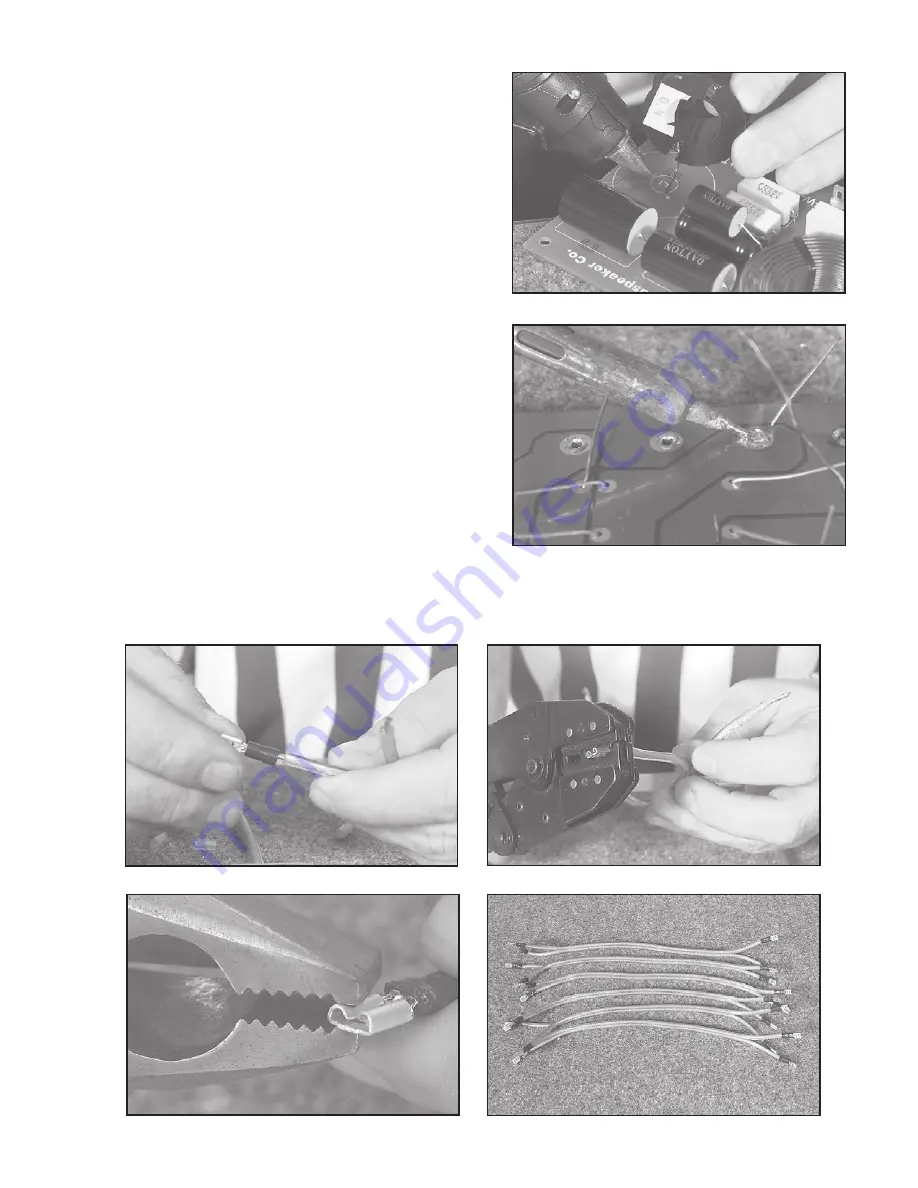

5. Cut the supplied wire into 6 pieces approximately 12"

long. Strip the insulation on all wires back

about 3/8"-1/2".

6. Using a crimp tool, crimp the .205 terminals on the wire leads. To ensure a tight connection, gently squeeze

the push on terminals with a small pair of pliers. Note: If you prefer, you can solder the wires directly to the

p.c. board and drivers instead of using the connectors.

3. To help reduce the risk of components rattling on

the p.c. board, (especially the inductors) use RTV

sealant or hot glue to mount the components to the

p.c. board. We recommend using hot glue due to its

faster setup time. If you use RTV sealant, you may

need to let it setup over night, before proceeding

with the assembly.