16

3

3

3

.

.

.

4

4

4

M

M

M

e

e

e

d

d

d

i

i

i

a

a

a

a

a

a

n

n

n

d

d

d

C

C

C

a

a

a

l

l

l

i

i

i

b

b

b

r

r

r

a

a

a

t

t

t

i

i

i

o

o

o

n

n

n

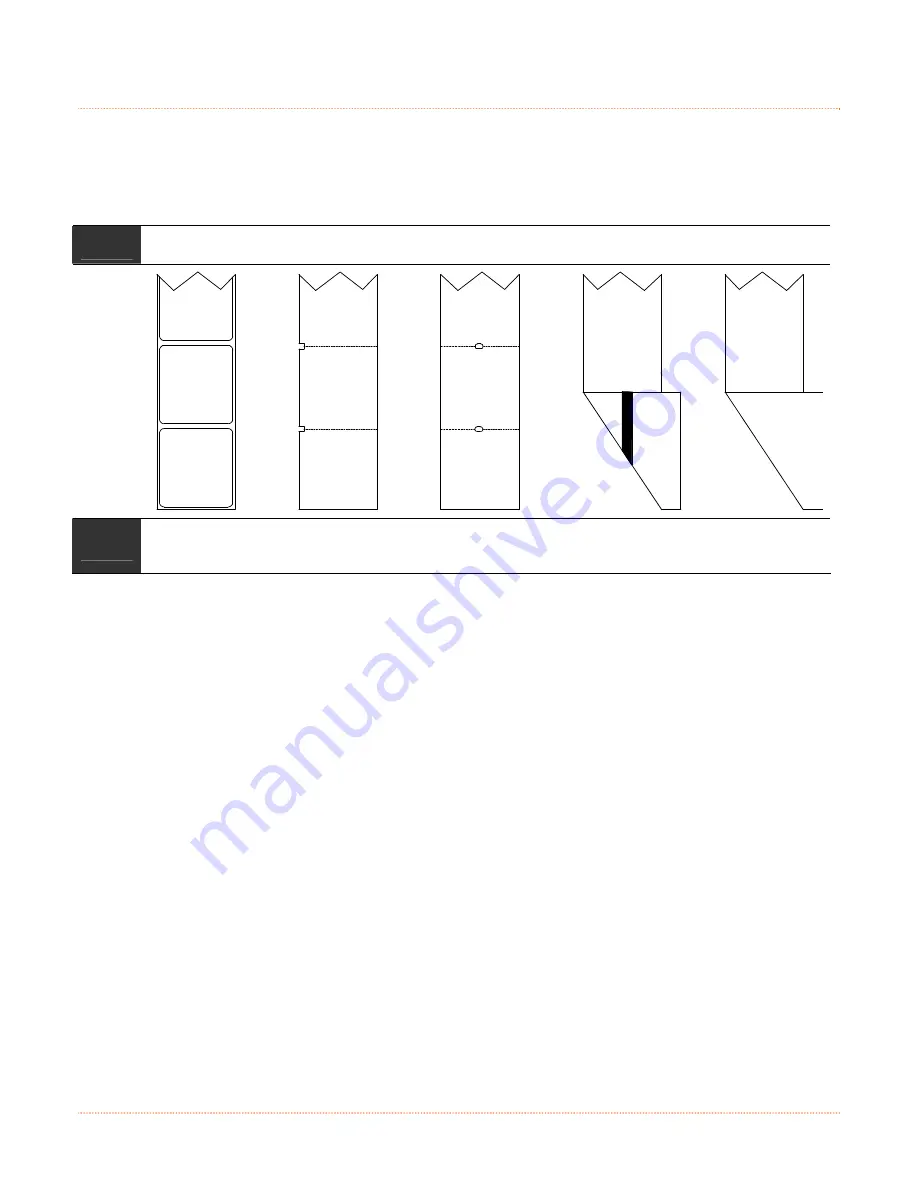

3.4.1 Selecting Media Type

To accommodate a variety of media types the printer is equipped with two sensors. A transmissive sensor

(for gap and notch type label media) and a reflective sensor (for “black mark” type label media). Several

media types and their proper sensor settings are shown below:

Media

Type

Gap Label Media

Notch Media

(Edge)

Notch Media

(Center)

Reflective Media

(Black Mark)

Continuous

Media

Sensor

Setting

Gap

Not Supported

Gap Reflective

Continuous*

*Requires the

“Continuous Label

Length” value to be set.

Most applications that use label media will use the default setting of “Gap”. However if “black mark” or

continuous media is being used this setting must be changed.

The Sensor Type setting can be changed using the NETira CT configuration utility, (see section 3.3 for

more information on NETira CT).

Summary of Contents for RL4

Page 1: ...User Guide ...

Page 2: ......

Page 10: ...4 ...

Page 38: ...32 ...

Page 44: ...A 4 ...

Page 52: ...B 8 ...

Page 66: ......