Fixed Addressing Mode

Fixed addressing mode allows for any pair of CAN message identifiers to be used for I/O module

communication.

In this mode, the I/O module relies on the RX_ID, TX_ID, and Frame parameters for communication with

the function block. Use the PLUS+1

®

Service Tool to set the proper values to match the function block and

to set the AddrMode.

Volatile Parameters

Once initial communication is established, all volatile parameter configuration messages are sent to the

I/O module.

Non-Volatile Parameters

After volatile parameters are configured, the function block sends a request for the configuration CRC to

the I/O module.

If this number matches the locally calculated value, then the configurations stored on the I/O module

match those set in the function block. If the numbers do not match, then all configuration commands are

sent and the CRC is requested again.

You can use the PLUS+1

®

Service Tool to access all non-volatile parameters on the I/O module.

Timing Configurations

Timing for messages to and from the I/O module is established after all other configurations are sent.

CAN Bus Load

Adjust the average amount of message transmissions on the CAN bus to allow for bursts and other

increased message transmission situations.

Any CAN bus has a maximum message transmission capacity. So, to allow for situations that can cause

increases in messages, minimize the CAN bus load.

The CAN bus load is the average amount of message transmission on a CAN bus. Use the PLUS+1

®

CG150

USB/CAN gateway and CANKing software to view CAN bus loads.

PLUS+1

®

I/O modules communicate with their associated controllers over a CAN bus. System developers

can adjust I/O module RepTime and TimeOut parameters to manage CAN bus loading. Increasing these

times reduces the CAN bus load. Decreasing these times increases CAN bus load.

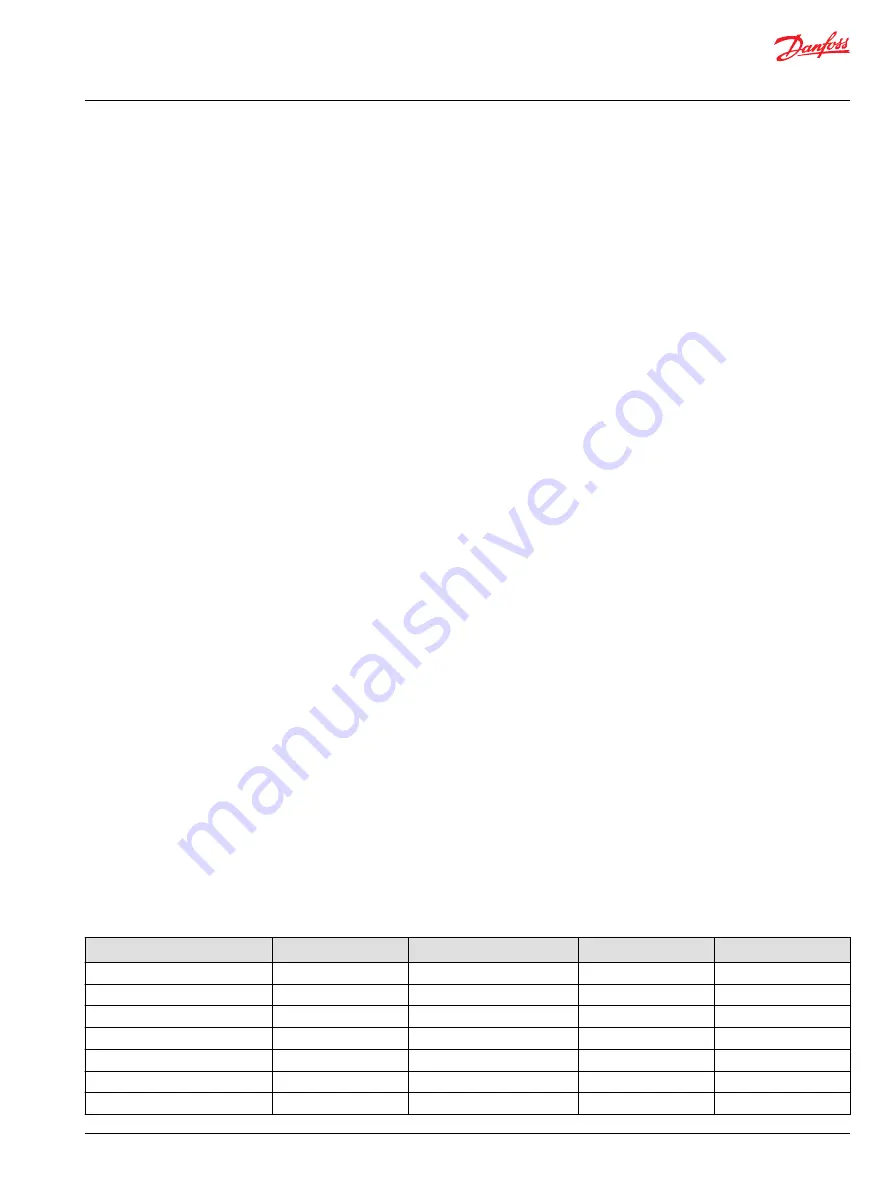

CAN Message Identifiers

The function block uses the following message identifiers to enable communication between the

controller and the I/O module.

I/O Module CAN Message Identifiers

CAN Shield Voltage [mV]

N1

KWP2000 Node

Tx ID

Rx ID

0 – 299

0

0

0x180

0x300

300 – 599

1

8

0x188

0x308

600 – 899

2

16

0x190

0x310

900 – 1199

3

24

0x198

0x318

1200 – 1499

4

32

0x1A0

0x320

1500 – 1799

5

40

0x1A8

0x328

1800 – 2099

6

48

0x1B0

0x330

User Manual

PLUS+1® Compliant OX024-x10 Function Block

OX024-x10 Function Block

©

Danfoss | July 2018

11063395 | AQ00000104en-US0101 | 11