IOM 1274-3 • CENTRIFUGAL WATER CHILLERS 24 www.DaikinApplied.com

Installation

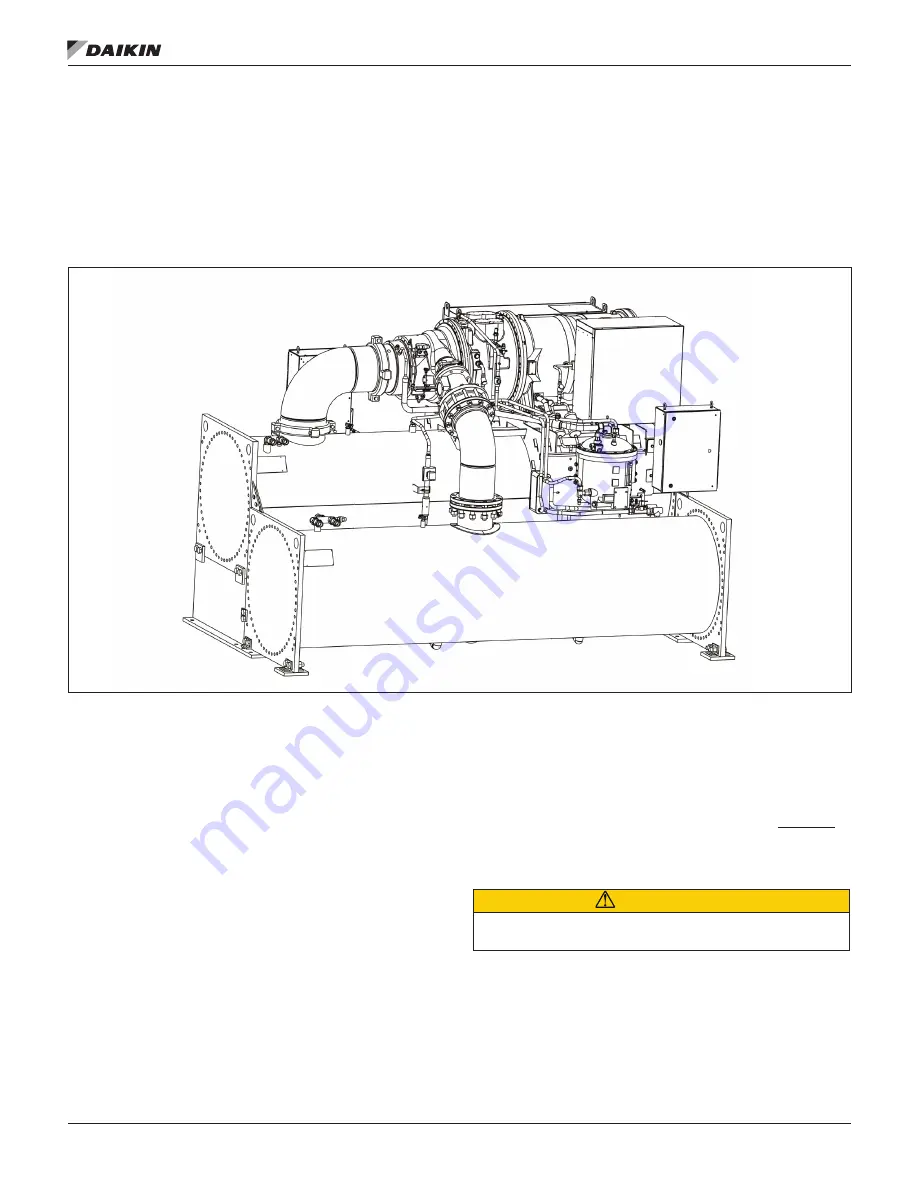

Retrofit Knockdown

Various knockdown arrangements are available as options and are ideal for retrofit applications with tight installation clearances.

Bolt-Together Construction - Type A

Chillers are built and shipped completely assembled with bolt-together construction on major components for field disassembly and

reassembly on the job site.

Figure 19: Bolt-Together Construction Option - Representative Schematic

Scope:

• Site disassembly and reassembly must be supervised or

completed by Daikin Applied service personnel.

• Unit is fully tested at the factory prior to shipment.

• The chiller is shipped completely assembled with the

full refrigerant charge, which must be recovered before

breaking any refrigerant connection.

• The refrigerant charge must be removed from the unit

if the vessels are to be separated. Exert the proper

precautions before attempting any disassembly, assume

the condenser isolation valves may have leaked and that

any component of the chiller may be pressurized with

refrigerant.

•

Suction and discharge lines have bolt-on flanges.

• Motor cooling line is brazed at mechanical connections.

•

Blockoff plates are required to cover any refrigerant

connection left open for extended periods of time. Contact

Daikin Applied service to obtain these parts.

• Check that no power is being applied to the unit. Before

disconnecting any wire, it is prudent to label its function

and connection point to facilitate re-connection.

• Unit ships with vessel and/or head insulation, if ordered.

• Unit ships with replacement refrigerant gaskets and

O-rings, stick-on wire ties, and touch-up paint. Some

insulation repair and touch-up painting may be required.

CAUTION

Standard torque specs must be followed when re-installing

bolts. Contact Daikin Applied service for this information.

NOTE: Schematic

shown without

waterboxes