Installation and operation manual

18

EWWD440~850AAYNNO**

Packaged water-cooled water chillers

4PW25558-1B

Checking the water system

■

Pump is filled with water

Fill the water piping, taking into account the minimum water

volume required by the unit. Refer to

Perform an air purge at the same time. Purging air is possible by

opening the airpurge valves on top of the condenser and

evaporator.

Operation with insufficient air purge can lead to drop of

performance.

■

Water pressure is less than the specified value

Check the chilled water side and condenser water side water

pressure.

Check the water pressure not only during normal flow, but also

at pump start.

If water pressure is over the maximum operating water pressure,

it may damage the machine.

In case of a standard model, the maximum operating water

pressure is 1.0 MPa both at chiller water side and condenser

water side.

■

No water leakage

Make sure that there is no water leakage from flanges or shells.

■

No mixing of air

Sound like "gobo gobo" while the water flows, or pressure

gauges attached to the equipment oscillate, or while the pump

operating current is unstable, means that air got mixed into the

water system.

Perform an air purge again.

Mixing of air not only makes the unit performance drop, but also

leads to damage of heat exchanger tubes inside the condenser

and evaporator.

■

Flow rate adjustment has been made

Adjust the flow rate to a proper rate using a flow meter and

adjust the rate in function of the pump characteristics chart.

Too low flow rate not only makes the unit performance drop, but

also leads to damage due to acceleration in adhesion of

contaminant and foreign matters to the heat exchanger tubes.

Excessive flow rate may lead to damage due to corrosion of heat

exchanger tubes.

■

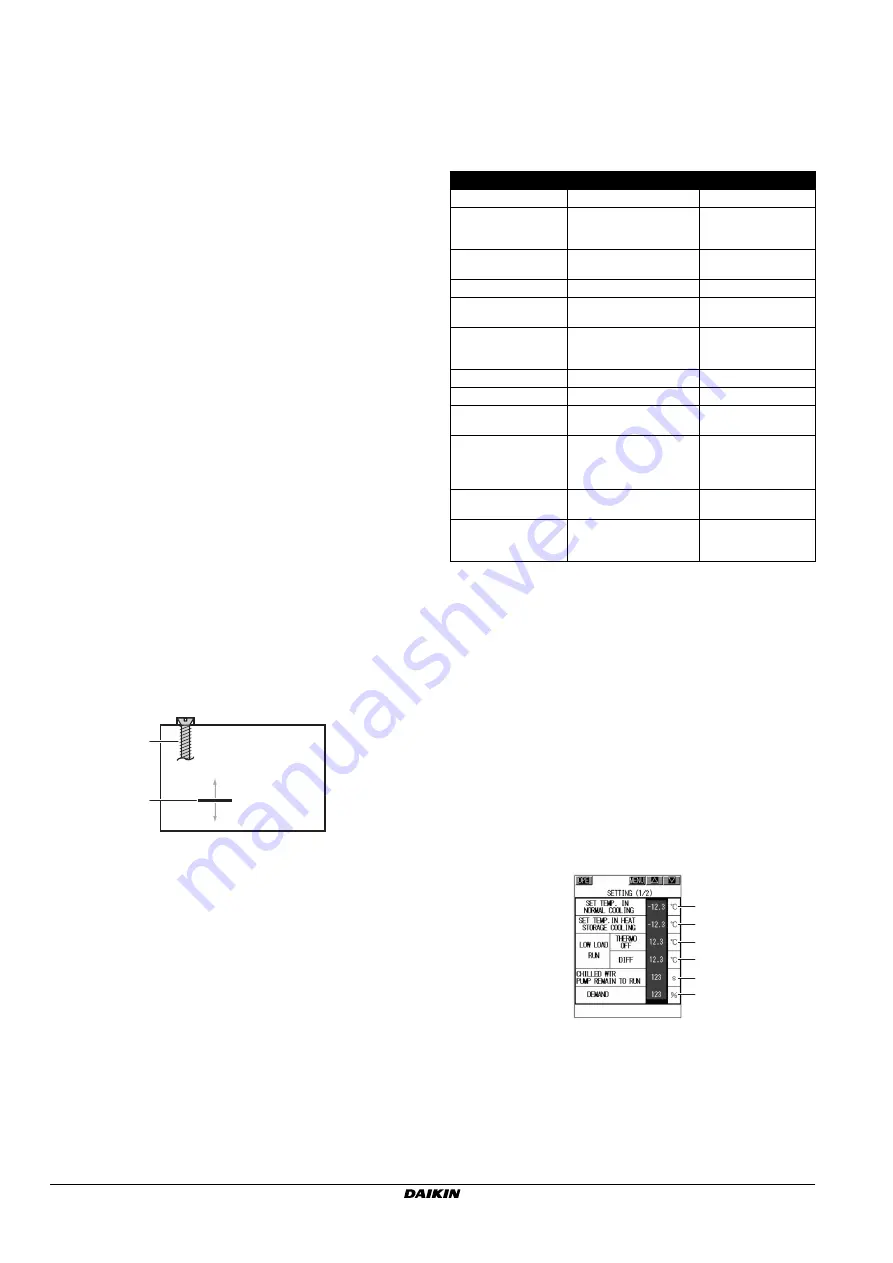

Make adjustment of water interruption relay (Protective device)

Be sure to make this adjustment. Local adjustment to the head

of equipment is required.

Remove the cover of the water interruption relay to observe the

movement of the internal metal piece contact. Check that the

metal piece contact moves upward when the water flows

and moves downward during water flow failure. If the contact

has already moved upward during water flow failure, turn the

adjusting screw clockwise by means of a screwdriver so that the

contact moves as indicated in the drawing. If the contact does

not move upward while water flows, adjust it by turning the

adjusting screw counterclockwise.

Checking the unit body

■

Open all shut-off valves indicated by a red label: “OPEN THIS

VALVE BEFORE OPERATION”.

All stopvalves, except those for charging of refrigerant or

oil, must be opened prior to start of the unit. Be sure to

check that they stay opened.

Stopvalves given below are installed.

•

Oil charge valve and refrigerant charge valve are used under

normally closed condition.

•

The pressure gauge valve (discharge pressure/suction pressure)

is designed as a 3-way valve taking maintenance of the pressure

sensors into account. Do not fully open these valves but keep

them at an intermediate opening.

•

Valves other than described in the 2 points above, are used under

normally opened condition.

Checking the settings on the controller

■

Prior to putting the unit into operation, change the settings of the

graphic panel display to the details that meet your configuration.

Refer to

"Operating the graphic panel display" on page 12

"Functions of this model" on page 21

■

The “SETTING (1/2)” screen represented below is the one of a

model with 2-temperature setting option. In case of the standard

model, the target temperature to be set will be represented with

“SET TEMPERATURE”.

1

Adjusting screw

2

Metal piece contact

3

When water flows

4

During water flow failure

2

1

3

4

Installation position

Stopvalve shape

Comment

Suction piping

Suction stop valve

Important

Liquid piping (Bottom)

Copper pipe stopvalve

Important

EWWD440/600: 1 point

EWWD850:

2 points

Condenser top

(Right and left)

Copper pipe stopvalve (3/8")

2 points, right and left

Condenser top (Center)

Copper pipe stopvalve (3/8")

—

Copper pipe from

condenser to compressor

Packless valve (3/8")

2 points,

right and left

Compressor

discharge chamber

(Oil discharge valve)

Copper pipe stopvalve (3/8")

2 points, right and left

Use at normally closed

condition.

Float chamber top

Copper pipe stopvalve (3/8")

—

Float chamber

Packless valve (5/8")

—

Evaporator bottom

Copper pipe stopvalve (3/8")

3 points,

right and left

Liquid pipe

(Refrigerant charge valve)

Copper pipe stopvalve (3/8")

EWWD440/600: 1 point

EWWD850:

2 points

Use at normally closed

condition.

Copper pipe from

evaporator to suction pipe

Copper pipe stopvalve (3/8")

—

Pressure gauge valve

3-way stopvalve for copper

pipe (3/8")

2 points,

Be sure to use at

intermediate opening

1

Set the chilled water outlet temperature target value.

The standard model is an outlet temperature control-only

model.

2

Make settings for the low load stop function.

3

Set the remaining operating time of the pump.

In case of models with 2-temperature setting option, also the

cooling water pump uses this setting.

The setting valve shall be 360 seconds or more.

4

Make setting of the current demand control.

1

1

2

2

3

4