3.7 Configuring the Welbee Inverter series welding power source

3-21

3.7 Configuring the Welbee Inverter series welding power

source

This section describes the front panel operations and internal functions of the welding power source when a

Welbee Inverter series welding power source is to be connected with the robot.

3.7.1 The welding power source operations when a robot is connected

When Welbee Inverter Series welding characteristics is connected to the robot, operable keys are

displayed in Table 3.7.1. The keys, other than the ones indicated, cannot be used.

All basic settings such as selecting the welding modes and setting the welding conditions are

performed by commands from the robots.

INFO.

Concerning the operation of the welding power source

For details on how to operate the welding power source, refer to its instruction

manual.

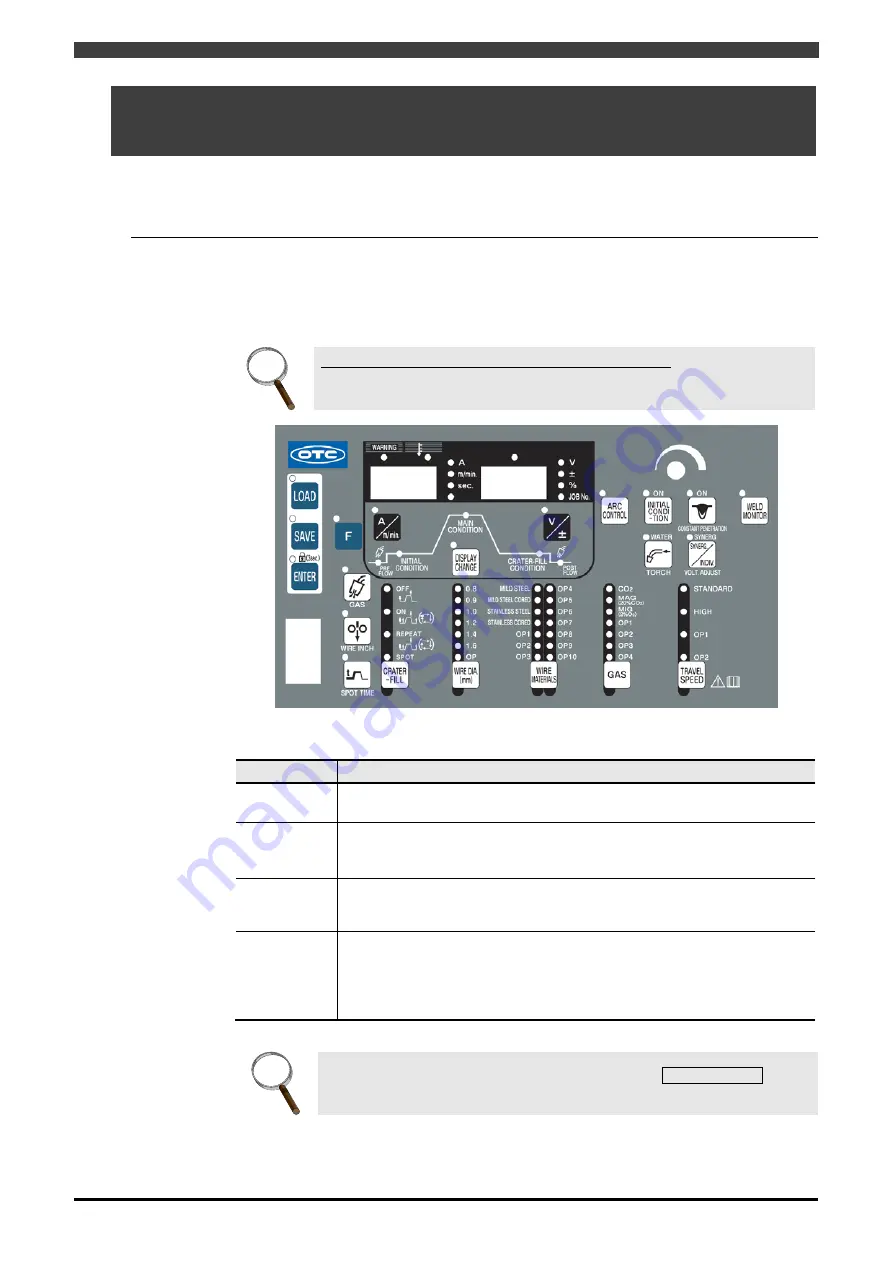

Figure 3.7.1 Welbee Inverter series welding power source Front Panel

Table 3.7.1

Keys that can be used when the welding power source is connected to a robot

Key name

Description of function

LOAD

Used when saving a simple data log to a USB memory. For details, see the

instruction manual for the welding power source.

ENTER

This key cannot work alone. Press [ENTER] key for a while (Approx. 3 sec.) to

switch the key lock ON/OFF.

When the key lock is ON, LED for [ENTER] key flashes.

GAS CHECK

When the key is pressed once, gas is discharged (for up to 2 minutes), and

the LED lights. When it is pressed again, the gas discharge stops, and the

LED goes off.

F

When the key lock is disabled, the functions (status settings) become

available by holding down this key for a few seconds. But the settings of the

functions are ignored when Welbee Inverter series is configured for a robot.

If holding down the [F] key when turning ON the power, the software version is

displayed.

INFO.

When set for the robot dedicated application, all LEDs in TRAVEL SPEED key are

OFF.

Summary of Contents for OTC Almega AX Series

Page 10: ......

Page 69: ...1 4 Welding mode lists 1 59...