6 MAINTENANCE

6.1

Planning of cleaning operations

The regular cleaning of the device keeps the print quality and extends its life. The following table shows the recommended

planning for the cleaning operations.

EVERY PAPER CHANGE

Printhead

Use isopropyl alcohol

Rollers

Use isopropyl alcohol

EVERY 5 PAPER CHANGES

Paper path

Use compressed air

Sensors

Use compressed air

EVERY 6 MONTHS OR AS NEEDED

Device case

Use compressed air or a soft cloth

For speciic procedures, see the following pages.

NOTE:

If you use the device in dusty environments, you must reduce the intervals between the cleaning operations.

39

Summary of Contents for PLUS2

Page 1: ...CUSTOM S p A USER MANUAL PLUS2 ...

Page 2: ......

Page 4: ......

Page 5: ...MANUAL For details on the commands refer to the manual with code 77200000002100 ...

Page 6: ......

Page 10: ...10 ...

Page 15: ...2 5 Key functions standby advance the paper preset length STANDBY Fast push 15 ...

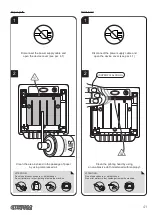

Page 18: ...4 To remove the fixing clips lift the lever shown in figure with a small screwdriver 18 ...

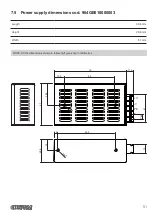

Page 22: ...Model with the 8 42 Vdc extended range module plugged USB Serial RS232 TTL Power supply 22 ...

Page 28: ...28 ...

Page 38: ...38 ...

Page 56: ...56 ...

Page 61: ...Device dimensions with the frame assembled 119 max 46 5 17 4 123 2 112x112 119 RS232 TTL 61 ...

Page 62: ...62 ...