16

Spacing

10'

15'

20'

7 ½"

.00096

.00143

.00246

8"

.00126

.00224

10"

.00069

.00103

.00177

Meter Man Acreage Counter

(Option)

Calibration

Use the formulas below to determine your imple-

ment calibration factor or refer to the predeter-

mined factors listed when using CrustBuster

drills.

DT = Distance traveled with one counter shaft rota-

tion (when using two magnets, divide DT by 2).

WW = Working Width of implement (in inches).

WW x DT/2 = Calibration factor

6272640

NOTE: Whenever a gear change is made on the

shaft being monitored, you will need to enter a

new calibration factor.

Entering Calibration Factor

1. Depress ON/C

2. Round off factor to 5 digits

3. Enter factor (remember decimal point)

4. Depress + key

5. Depress = key

6. Depress decimal point (screen display 0)

CrustBuster Drill

Meter Man Factors by Model

4600 Drill

Sprocket Box Adjustment

The sprocket box design will enable the operator

to set a wobble slot width once for a given seed

size and change rates by changing the speed of

the seed shaft.

Choose a range of seeding rates that you wish to

operate in, set the slot width as indicated by the

chart and simply change knob position with the

slide handle to select seed rate.

A narrow slot width will produce more even

distribution and spacing in the row.

For round seeds, the ideal slot width can be

determined by measuring seed size. To attain

singular file flow of seeds from the wobble slot

seed cup, the slot width should be greater than

one and one half (1 ½) times the average seed

size, but less than two (2) times the average size.

Ideal Slot Width =

Greater than (>) 1½ times seed size

Less than (<) 2 times seed size

To determine average seed size, lay out 20-30

seeds in single file, each seed touching each

other. A short piece of angle iron can help align

the seeds evenly. Measure distance from end to

end with a ruler. Divide that measurement by the

number of seeds to equal the average seed size.

Multiply average seed size times 1½ to find the

minimum width. Multiply average seed size times

2 to find the maximum width. The slot width

should be ideal when set between these values.

Example:

30 seeds measure 9 inches.

9 " divided by 30 seeds

= .30"

.30" times 1.5

= .45"

.30 times 2

= .60"

Ideal slot width is greater than .45",less than .60"

Ideal slot width

= ½"

Refer to seed chart ½" column as a starting point

for setting final seed rate.

To change position, move throw-out lever toward

the rear to disengage the chain from the lower

sprocket. Pull the spring loaded collar outward

with two fingers and slide side to side to the

desired gear position. Pull throw-out lever for-

ward to re-engage the chain.

Sprocket Box

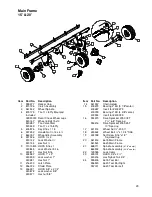

Summary of Contents for 4600 Series

Page 1: ...4600 SERIES ALL PLANT DRILL 09 03 605717 ...

Page 6: ...4 Safety Instructions ...

Page 7: ...5 Safety Instructions ...

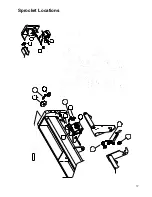

Page 19: ...17 Sprocket Locations ...

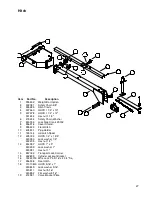

Page 20: ...18 ...

Page 34: ...32 Grain Box 10 ...

Page 36: ...34 Grain Box 15 20 ...

Page 44: ...42 All Plant Opener Assembly ...

Page 46: ...44 Gear Box Assembly 10 ...

Page 48: ...46 Gear Box Assembly 15 20 ...

Page 61: ...58 a Harrow Layouts 10 Drill 7 Spacing 10 Drill 10 Spacing ...

Page 62: ...58 b ...

Page 63: ...59 15 Drill 8 Spacing 15 Drill 7 Spacing Harrow Layouts ...

Page 64: ...60 15 Drill 10 Spacing 20 Drill 7 Spacing Harrow Layouts ...

Page 65: ...61 20 Drill 8 Spacing 20 Drill 10 Spacing Harrow Layouts ...

Page 66: ...62 15 Legume ...

Page 68: ...64 20 Legume ...

Page 71: ...67 Light System ...

Page 72: ......

Page 73: ...69 Fertilizer Unit ...

Page 76: ...72 4615 Sprocket Locations Fertilizer Unit ...

Page 78: ...74 4615 Drive Assembly Fertilizer Unit ...

Page 80: ...76 4615 Gear Box Fertilizer Unit ...

Page 82: ...78 4615 Box Bottom Assembly Fertilizer Unit ...

Page 84: ...80 4600 All Plant Feed Tubes Fertilizer Unit ...

Page 86: ...P O Box 1438 Dodge City Kansas 67801 620 227 7106 ...