6

Field Operating Checklist

____ Inflate tires to recommended air pressure.

____ Lubrication as required.

____ Seed shafts turned manually to check for obstructions and improper chain alignment on drive

sprockets.

____ Correct sprocket selection and slot width for seed type and size.

____ Calibration as required for accuracy.

____ Drill adjusted at hitch for level field operation.

____ Cylinder stop set for proper toolbar rotation.

____ Down pressure set for soil conditions.

____ Acre meter reset.

____ Lower drill while moving forward to avoid plugging openers.

____ Check seed depth and adjust accordingly.

____ Allow no riders.

____ After approximately 10 hours, check tool bar bolts, wheel bolts, presswheel swivel bolts, etc..

Make sure they are tight.

Transport Instructions

Before attempting to operate the lift cylinder, remove transport lock. Store cylinder lock on the

holder attached to the front of the weight bar bracket. When traveling long distances, it is

recommended that the transport lock be installed, pressure relieved from the hydraulic hoses

and hoses hooked to the tractor. If trailing behind a towing vehicle, the hydraulic hoses should

be stored in the slotted storage in the tongue cover.

NEVER use an unsecured pin in draw bar.

DO NOT attempt to remove the cylinder at any time for transport or field operations.

Stow the adjustable jack on top of the tongue mounting stub to avoid interference with main

tractor wheels in tight turns and make sure 3-pt linkages are fully raised.

Connect the 7 pin lighting plug to the tractor receptacle and use at all times. Confirm the

correct lights are operating if your tractor is not wired by industry standard code. Standard 7

pin receptacles are available through your dealer, local truck supply stores, and auto parts

facilities.

Always attach the safety chain to the tractor drawbar system.

Disconnect drive chain and store on the "dummy" sprocket when traveling long distances.

If your drill is equipped with hydraulic markers, the safety chains should be attached to the

marker to avoid catastrophic injury to oncoming vehicles.

Maximum allowable speed; 25 mph.

CAUTION! Your drill may weigh more than the towing vehicle. The drill is NOT

equipped with brakes. Exercise extreme caution!

Summary of Contents for 4600 Series

Page 1: ...4600 SERIES ALL PLANT DRILL 09 03 605717 ...

Page 6: ...4 Safety Instructions ...

Page 7: ...5 Safety Instructions ...

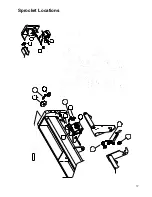

Page 19: ...17 Sprocket Locations ...

Page 20: ...18 ...

Page 34: ...32 Grain Box 10 ...

Page 36: ...34 Grain Box 15 20 ...

Page 44: ...42 All Plant Opener Assembly ...

Page 46: ...44 Gear Box Assembly 10 ...

Page 48: ...46 Gear Box Assembly 15 20 ...

Page 61: ...58 a Harrow Layouts 10 Drill 7 Spacing 10 Drill 10 Spacing ...

Page 62: ...58 b ...

Page 63: ...59 15 Drill 8 Spacing 15 Drill 7 Spacing Harrow Layouts ...

Page 64: ...60 15 Drill 10 Spacing 20 Drill 7 Spacing Harrow Layouts ...

Page 65: ...61 20 Drill 8 Spacing 20 Drill 10 Spacing Harrow Layouts ...

Page 66: ...62 15 Legume ...

Page 68: ...64 20 Legume ...

Page 71: ...67 Light System ...

Page 72: ......

Page 73: ...69 Fertilizer Unit ...

Page 76: ...72 4615 Sprocket Locations Fertilizer Unit ...

Page 78: ...74 4615 Drive Assembly Fertilizer Unit ...

Page 80: ...76 4615 Gear Box Fertilizer Unit ...

Page 82: ...78 4615 Box Bottom Assembly Fertilizer Unit ...

Page 84: ...80 4600 All Plant Feed Tubes Fertilizer Unit ...

Page 86: ...P O Box 1438 Dodge City Kansas 67801 620 227 7106 ...