10

Field Operation

Conventional Field Conditions

For tilled field conditions, the lightest spring

setting (top notch) is recommended. More

weight will be transferred to the carrying wheels

of the drill when the toolbar is rotated. Behind

tractor and drill tires it may be necessary to

adjust individual row units for extra down pres-

sure or different depth setting. Setting the

drill in conventional tillage will be easier if

the tillage trips are kept shallow (2" - 4").

If the first notch presents too much down pres-

sure, the down pressure spring assembly can

be removed. With the spring assembly re-

moved, the effective down pressure of the

opener is approximately 60#.

With the openers rotated clear of the ground,

release the latches on the spring top assem-

blies. With the spring top ears between the

parallel arms, raise the opener halfway and

push the bottom of the spring and spring pin

forward out of the cradles.

Minimum Tillage Conditions

The most challenging condition is often pre-

sented when a high level of residue is present

in a "loose" soil environment. The opener

blades will not cut residue cleanly and can often

have a tendency to push or "bulldoze" residue

ahead of the opener discs.

For minimum tillage operations, the lightest

spring (top notch) is recommended. Firming

the ground using a culti-packer or similar tool

can aid in packing the residue for better cutting

and blade penetration with less hairpinning.

The All Plant drill will work well in minimum

tillage conditions if a "stale seedbed" is created.

Soil worked at an earlier date, and allowed to

firm and crust over can give the opener more

resistance, allow for better cutting action, and

create a firmer seed furrow. The first or second

notch will usually provide enough down pres-

sure to penetrate the soil.

No-Till Conditions

No-till presents many different conditions.

Residue level and condition, previous tillage

strips (ridges, plow dead furrows), soil type, soil

moisture and rocky conditions all increase the

demands on the no-till drill. Many variables and

conditions not removed by tillage trips require

greater attention to settings and speed. In

some circumstances, it may be desirable to drill

at a slight angle to existing rows. This will also

randomize the opener disc wear and extend the

maintenance interval for new blades.

As a general rule, less than ideal conditions will

require slower speeds, to reduce hairpinning,

improve opener penetration and residue cut-

ting, reduce rock damage, and maintain good

furrow formation and seed placement.

It is recommended you set the drill beginning

with light down pressures and work your way

up to heavier settings. If the presswheel

presses firmly on the seed slot and control

depth evenly, it is unnecessary to add more

pressure. When increased down pressure

does not improve penetration, or carrying

wheels lose ground contact (and seed drive

shaft stops), begin adding ballast with weight

bars and/or suitcase weights.

Summary of Contents for 4600 Series

Page 1: ...4600 SERIES ALL PLANT DRILL 09 03 605717 ...

Page 6: ...4 Safety Instructions ...

Page 7: ...5 Safety Instructions ...

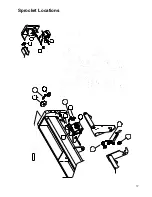

Page 19: ...17 Sprocket Locations ...

Page 20: ...18 ...

Page 34: ...32 Grain Box 10 ...

Page 36: ...34 Grain Box 15 20 ...

Page 44: ...42 All Plant Opener Assembly ...

Page 46: ...44 Gear Box Assembly 10 ...

Page 48: ...46 Gear Box Assembly 15 20 ...

Page 61: ...58 a Harrow Layouts 10 Drill 7 Spacing 10 Drill 10 Spacing ...

Page 62: ...58 b ...

Page 63: ...59 15 Drill 8 Spacing 15 Drill 7 Spacing Harrow Layouts ...

Page 64: ...60 15 Drill 10 Spacing 20 Drill 7 Spacing Harrow Layouts ...

Page 65: ...61 20 Drill 8 Spacing 20 Drill 10 Spacing Harrow Layouts ...

Page 66: ...62 15 Legume ...

Page 68: ...64 20 Legume ...

Page 71: ...67 Light System ...

Page 72: ......

Page 73: ...69 Fertilizer Unit ...

Page 76: ...72 4615 Sprocket Locations Fertilizer Unit ...

Page 78: ...74 4615 Drive Assembly Fertilizer Unit ...

Page 80: ...76 4615 Gear Box Fertilizer Unit ...

Page 82: ...78 4615 Box Bottom Assembly Fertilizer Unit ...

Page 84: ...80 4600 All Plant Feed Tubes Fertilizer Unit ...

Page 86: ...P O Box 1438 Dodge City Kansas 67801 620 227 7106 ...