11

Calibration, Seed Rates and Sprocket Box

Calibration/Drilling Rates

Planting the right rate can be frustrating.

Sometimes the end result is not what the rate

chart indicates. Seeding rate is affected by

seed size, seed treatments, foreign material,

test weight, and tire air pressure.

1. Always plant clean seed.

2. Check tire air pressure.

3. Seed treatments vary by type and time of

application.

Some seeds are treated at the processor. Drill

box treatments are common methods of appli-

cation. Each of these can "gum" up the wobble

slot cup halves and reduce final seeding rate.

Treated seed often flows differently than non-

treated seed.

A general method for checking quantities drilled

is as follows:

1. Set drill for desired seeding rate.

2. Fill the box level; then pull drill for a short

distance to settle seed. Refill box exactly

level full.

3. Drill a calculated one acre.

4. Carefully weigh the seed required to refill

the box level full.

5. Compare the amount used versus that

stated on the rate chart.

6. Adjust seeding rate by changing the

sprocket combination or wobble slot width.

One method involves catching seed from one

or more seed cups and utilizing a density scale

to determine actual rates. These scales are

commercially available, inexpensive and very

easy to use. Information can be obtained from

CrustBuster®/Speed King, Inc.

Sprocket Box Operation

The sprocket box design will enable the opera-

tor to set a wobble slot width once for a given

seed size and change rates by changing the

speed of the seed shaft. Choose a range of

seeding rates that you wish to operate in, set

the slot width as indicated by the chart and

simply change knob position with the slide

handle to effect seed rate. A narrow slot width

will produce more even distribution and spacing

in the row.

When changing derailleur, be sure openers

are rotated out of ground.

To change position, move throw-out lever

toward the rear to disengage the chain from the

lower sprocket. Pull the spring loaded collar

outward with two fingers and slide side to side

to the desired gear position. Pull throw-out

lever forward to re-engage the chain.

Sprocket Box

Summary of Contents for 4600 Series

Page 1: ...4600 SERIES ALL PLANT DRILL 09 03 605717 ...

Page 6: ...4 Safety Instructions ...

Page 7: ...5 Safety Instructions ...

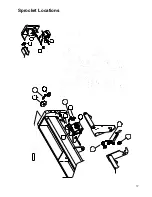

Page 19: ...17 Sprocket Locations ...

Page 20: ...18 ...

Page 34: ...32 Grain Box 10 ...

Page 36: ...34 Grain Box 15 20 ...

Page 44: ...42 All Plant Opener Assembly ...

Page 46: ...44 Gear Box Assembly 10 ...

Page 48: ...46 Gear Box Assembly 15 20 ...

Page 61: ...58 a Harrow Layouts 10 Drill 7 Spacing 10 Drill 10 Spacing ...

Page 62: ...58 b ...

Page 63: ...59 15 Drill 8 Spacing 15 Drill 7 Spacing Harrow Layouts ...

Page 64: ...60 15 Drill 10 Spacing 20 Drill 7 Spacing Harrow Layouts ...

Page 65: ...61 20 Drill 8 Spacing 20 Drill 10 Spacing Harrow Layouts ...

Page 66: ...62 15 Legume ...

Page 68: ...64 20 Legume ...

Page 71: ...67 Light System ...

Page 72: ......

Page 73: ...69 Fertilizer Unit ...

Page 76: ...72 4615 Sprocket Locations Fertilizer Unit ...

Page 78: ...74 4615 Drive Assembly Fertilizer Unit ...

Page 80: ...76 4615 Gear Box Fertilizer Unit ...

Page 82: ...78 4615 Box Bottom Assembly Fertilizer Unit ...

Page 84: ...80 4600 All Plant Feed Tubes Fertilizer Unit ...

Page 86: ...P O Box 1438 Dodge City Kansas 67801 620 227 7106 ...