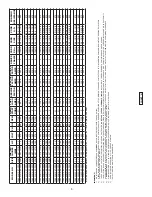

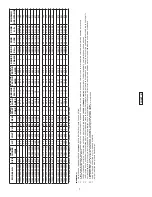

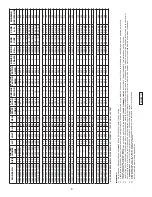

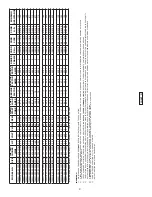

20

PARTS LIST

ITEM QTY

PART NO.

DESCRIPTION

MATERIAL

2 10 136284

Screw, SHCS, M12 x 1.75 x 25

300 SS

3 2 138312

Pin, Spring, .13 x .20

300 SS

4A 1 138315

Seal, Mech, 2.88”

C/CE/B

4B 1 138315SD

Seal, Mech, 2.88”

SC/SC/B

6

1

See Table

Impeller

Ductile Iron

7 1 Q21-20-J8

Key, .25 x .25 x 1.50”

303 SS

8 1 138310

Screw, SHCS, M18 x 2.50 x 50

304 SS

8A 1 138543

Washer, Impeller, .75 X 2.44

18-8 SS

9- 1 M-6614

O-Ring, -465, 18.0” ID

Buna-N

9- 1 125857-360

O-Ring, M3 x 360, 70 DURO

Buna-N

9-

1

125857-295

O-Ring, M3 x 295, 70 DURO

Buna-N

9- 1 018386

O-Ring, -276, 10.98” ID

Buna-N

9- 1 2-31003-281

O-Ring, -281, 14.98” ID

Buna-N

9- 1 2-31003-282

O-Ring, -282, 15.96” ID

Buna-N

10

1

See Table

Volute

Cast Iron

11

2

See Table

Volute Wear Ring (as required)

Bronze

11A

2

See Table

Impeller Wear Ring (as required)

Bronze

14 3 014270-SS

Plug, Pipe, .375-18NPT

300 SS

15 34 138179

Screw, SHCS, M16 x 2.00 x 40

300 SS

16 1 Q10-51-E4

Bearing, Ball, 6310, 4.33

Steel

17 1 138314

Bearing, Ball, 3315A

Steel

18 2 138316

Washer, Spring, Wavy, 110mm

Steel

19A 2 138311

Ring, Retaining, EXT, 2.88"

SS

19B

1

138313

Ring, Retaining, EXT, 3.00"

Steel

20 1 130073

Ring, Retaining, 5000-433-S

SS

24 2 125856

Sensor, Moisture, .250-18NPT

PP / SS

25 1 138175

Block, Terminal, 9 Pin, Male

Valox/Brass

26

1

138546

Handle, Lifting, 32FR

304 SS

27 1 127267

Resistor, Moisture, Sensor

28

1

138545

Pin, Dowel, 7/16” D, 5/8” LG

Steel

35 1 138328-XX-XXX

Stator, 32FR

36

1

138327-XX-XXX

Rotor, Assy, 32FR, RB

37 2 127234B Wire, Orange, 36”, BAR/BAR

38 1 138054

Housing, Motor, 32FR

Class 30 CI

39 1 138051-465

Plate, Seal, 465mm, 32FR

Class 30 CI

40 1 138057

Cap, Motor, 32FR

Class 30 CI

41 1 138544

Ring, Retaining, INT, 160mm

Steel

42 2 138310

Screw, SHCS, M18 x 2.50 x 50

SS

43 1 138056

Plate, Bushing, Retainer

Steel

44 1 138055

Bushing, BRZ, Oil, 2.88

Bronze

47 1 138053

Bracket, Bearing, 32FR

Class 30 CI

51 2 134013

Connector, Wire, Clip

PC

52 3 138542

Screw, SHCS/SF, M8 x 1.25 x 12

Steel

53 1 625-01551

O-Ring, 2-232, 2.75” ID

Buna-N

54

1

138547

Pin, Dowel, .313” x 1.50” LG

18-8 SS

55 1 138549

Ring, Retaining, INT, VH-375

Steel

56 4 001628

Screw, Drive, U #4, .187”

300 SS

57 1 127264C

Nameplate, Main

SS

58

1

See Table

Cord

59 1 2-31003-248

O-Ring, -248, 4.75” ID

Buna-N

60 2 138559

Retainer, Seal, 2.88”

SS

61 1 138563

Tag, Caution, Cord, Yellow

70

-

Paint

(As Needed)

Epoxy Paint (Kits Masked and Painted)

Epoxy

71

.001oz 126638

Adhesive, #RC603

72

1020oz 029034

Oil, Cooling

Oil

Summary of Contents for DEMING 7365N-X54-95-30N

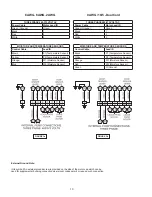

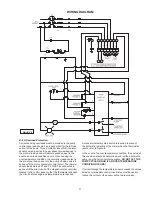

Page 18: ...18 FIGURE 9 Vortex Enclosed CROSS SECTIONS FIGURE 10 ...

Page 19: ...19 EXPLODED VIEWS FIGURE 11 ...

Page 22: ...22 Notes ...