11

32. Trim the casing half gaskets fl ush with casing at end

of

stuffi ng box using a putty knife, fi le, etc.

33.

Mechanical seal pumps:

Remove rag or towel from

between seal cap and rotating element of seal that

was placed here in Step 15. Slide seal element into

place, check to be sure seal faces are clean, and

that the sealing washer is properly positioned in

retainer. Push seal cap and seal cap gasket in

evenly far enough to install seal cap bolts and washers.

Care must be taken to turn both bolts equally to

prevent cocking the seal cap and chipping or cracking

the carbon sealing washer. Check to make sure

gasket is in proper position. Note that these bolts only

need to be tight enough to compress gasket to seal.

34.

Pack Pumps:

Install the gland halves (Note: These

are in sets and marked as such and cannot be

mixed. The one with the hole goes on bottom), gland

washers and nuts. Tighten nuts down fi nger tight.

Be sure the gland has entered the box at least 1/8”.

If the packing will not compress to allow this, remove

one ring of packing. The breaking-in period of the

packing is more important in the satisfactory

performance of a stuffi ng box. When the pump

is returned to service, additional care must be given

the packing box to insure proper packing life. It is

necessary to allow 60 to 100 drops leakage per

minute through the packing for lubrication purposes.

If

the

fl ow rate is other than this, the gland nuts

should be loosened or tightened one fl at (1/16 turn)

at a time to acquire the correct leakage (both nuts

must be turned equally to prevent cocking the gland)

allow at least ten minutes between adjustment for

the leakage rate to stabilize. When in doubt, choose

the greater leakage rate, since overly tightened

packing will ruin the packing as well as the sleeve.

35. Install relief cooling, abrasive separator, fl ush lines,

vent cock, drain plug and other fi ttings that were

removed during disassembly.

36. Open vent cock to evacuate air. Slowly open suction

valve, when air has evacuated close vent cock and

fully open suction valve. Open discharge valve

to its original position. Check for leaks and turn

rotating assembly. Never start a pump until all air

and vapor has been evacuated. Without fl uid around

it, the mechanical seal may be ruined within a few

seconds of operation. It is possible that the

mechanical seals may drip the fi rst few minutes to an

hour of operation.

39. Install coupling sleeve, adjust and align coupling.

Refer to alignment procedure section.

40. Install coupling guard

41. Turn power to pump on. Start and run pump

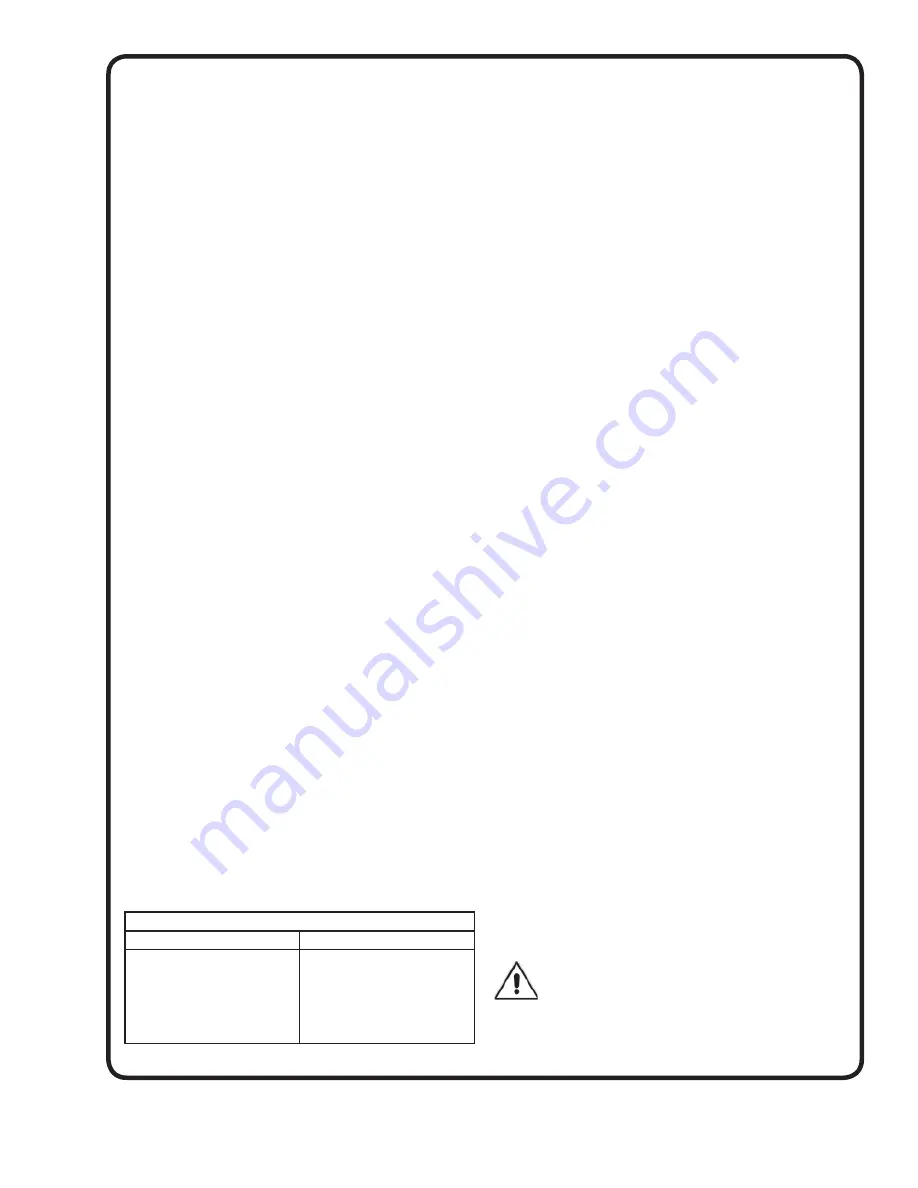

TORQUE REQUIREMENTS

SIZE

FOOT-POUNDS

3/8-16

1/2-13

5/8-11

3/4-10

7/8-9

1-8

21.7

43.5

86.0

152.0

222.0

307.0

FOOTNOTE:

The rotating assembly can be adjusted by

loosening the three bolts that holds the bearing housing to

lower case half on one end or the other, or both. Lift up on

bearing housing and snug bottom bolt, then using a rubber

hammer, lightly tap housing while turning shaft. Repeat

until best position is found, then tighten all bolts.

5. DOUBLE-WEAR RING IMPELLERS:

Remove -

Wear rings are pressed and bolted on and must

be removed with puller or by drilling through the width of

the wear ring and removing with a chisel after the wear

ring locking screws are removed. Wear ring locking screws

can be removed by center punching and drilling out using

a 7/32” drill.

Install -

Install wear rings onto impeller hubs. Drill through

each wear ring and impeller hub in two places 180° apart,

using a number 7 drill, tap holes with 1/4-20UNC tap

stopping 1 or 2 threads short of tapping through. Thread

screws into tapped holes until tight or fl ush with inside of

impeller hub. Cut screws off fl ush with outside diameter of

wear ring and fi le smooth any burrs or protrusions.

6. CHANGE ROTATION:

Follow disassembly instructions Steps 1 thru 24. Turn both

impellers and interstage diaphragm around and slide back

onto shaft. The mark put on impeller in Step 16 should

be opposite the coupling (driver) end of shaft. Follow

reassembly instruction Steps 1 thru 10, Steps 17 thru 39.

There is only one correct way for impeller to go in casing.

If pump is mounted on base, unbolt and turn casing

around 180°.

7. SEAL REPLACEMENT (Inboard):

Follow disassembly instructions Steps 1 thru 4, remove

fl ush line to seal cap only, 5, 6 remove three motor

mounting bolts and turn motor enough to allow for coupling

removal, 7, 16 thru 21.

Follow reassembly instructions Steps 5, 6, 7, 9, 10. 16, 17,

22, 28, 32, 34, 35, put motor back into place, 36 & 27.

8. SEAL REPLACEMENT (Outboard):

Follow disassembly instructions Steps 1, 2, 3, remove

fl ush line to seal cap, 7, 25 thru 28, then 18 thru 21.

Follow reassembly instructions Steps 5, 6, 7 thru 15, 21,

32, 34, 35.

9. SHAFT SEAL - TYPE 1 INSTALLATION

Remove top half of the casing. After determining size and

type of pump from name plate, fi nd setting location of

seal collar, either X, Y, or Z, from Table 1. If the seal collar

needs resetting, rotate it 30° before tightening set screws.

IMPORTANT ! - DO NOT ATTEMPT TO

REINSTALL ANY USED PARTS OF THE SEAL,

EXCEPT THE SPRING AND COLLAR.

Summary of Contents for Deming 5260 Series

Page 7: ...7 Figure 3 ...

Page 22: ...Notes ...