9

2. PACKING BOX

The packing glands should be adjusted occasionally to

insure proper packing lubrication. A slow dripping through

the gland is recommended for good lubrication and long

packing and shaft sleeve life.

When installing new rings of packing, clean packing box

and inspect parts for any damage. If the shaft sleeve is

worn or grooved, it should be replaced. New packing will

not do an adequate sealing job on a worn shaft sleeve.

Insert two new rings of packing in front of lantern ring.

Stagger joints to minimize leakage.

Tamp each ring in place. Replace lantern ring. Add two

rings of packing behind lantern ring. Replace gland and

bolts, rotate shaft and tighten gland securely. Loosen the

gland and add the fi nal ring of packing. Be sure lantern

ring is positioned to receive lubrication through orifi ce.

Tighten nuts securely to seat packing and rotate shaft.

After rotating several turns, loosen nuts to fi nger tight for

starting.

3. DISASSEMBLY

The following procedure is for complete disassembly of

the pump. If complete disassembly is not necessary, use

only those steps which apply.

1. Shut off and lock put power to motor.

2. If hot liquids are being pumped, care should be

taken so personal injury is not incurred during

disassembly.

3. Totally depressurized pump and associated piping

by closing suction and discharge valves, to isolate

pump from system. Slowly open vent cock and then

remove drain plug from casing.

4. Remove all relief cooling, fl ush lines from pump.

5. Remove coupling guard

6. Loosen coupling set screws. Move coupling hubs

back and remove coupling sleeve.

7. Remove seal cap bolts by alternating the loosening

of the bolts. Exercise care to not cock the seal cap,

which could chip or crack the carbon seal face.

(Pack pumps remove packing gland).

8. Remove case rollpins. (Used to align upper and

lower

halves).

9. Using some type of overhead lifting device, (a

frame, come a long chain fall, etc) hook onto the

two eyebolts or lifting lugs on top half of casing.

10. Remove bolts holding casing halves together. Turn

jackscrews in to separate the casing halves.

11. Set top half out of the way on a piece of cardboard

or wood, taking care not to scratch gasket surface.

12. Place casing gasket, as well as all other gaskets in

water to keep them from drying out and shrinking

13. Check seal setting (distance from machined surface

at the end of the stuffi ng box area to the seal collar).

This will need to be known to reset collar in the

proper position, if disassembly requires removal of

collar. (See Chart “Construction Details”).

14. Using overhead lifting device, hook onto rotating

assembly with nylon straps or rope, to not scratch

shaft. Remove bolts holding bearing housing to

pump casing. Remove rotating assembly from casing.

15. Mark impeller on coupling side , so if required to

remove from shaft, it will be reassembled correctly.

16. Remove coupling hub from pump shaft (may

require use of a gear or wheel puller). Remove

coupling key. (This is inboard side).

17. Remove three capscrews holding bearing cap and

bearing housing together. Remove bearing housing

(tap off using rubber hammer). Using a gear or wheel

puller, pull bearing off of shaft.

18. Remove bearing cap and water defl ector (rubber

slinger) from shaft.

19. Loosen set screws in sleeve lock nuts, using a

spanner wrench. Remove (when used).

20. Remove seal cap. (Stationary seal seat is

pressed

in).

21. Remove rotating seal assembly. (Packing and

packing bushing on pack pumps).

22. Slide shaft sleeve off

23. Remove both impellers and interstage diaphragm,

impeller key and casing rings.

24. Remove three capscrews holding bearing cap and

bearing housing together (outboard). Remove

bearing housing (Tap off using rubber housing).

25. Remove retaining ring (bearing snap ring).

26.

Remove bearing (outboard) using gear or wheel puller.

27. Remove thrust collar. (Remove bearing cap before

thrust collar on verticals).

28. Repeat Steps 20 through 25.

4. REASSEMBLY

The following procedure is for the complete assembly of

the pump. This procedure must be followed for satisfactory

operation. If pump is not completely disassembled, use

only the steps that are applicable.

1. Install both impellers and interstage diaphragm,

with gasket between impellers. Make sure impeller

is installed on shaft the same way it came off, per

mark put on it during disassembly. (Double check

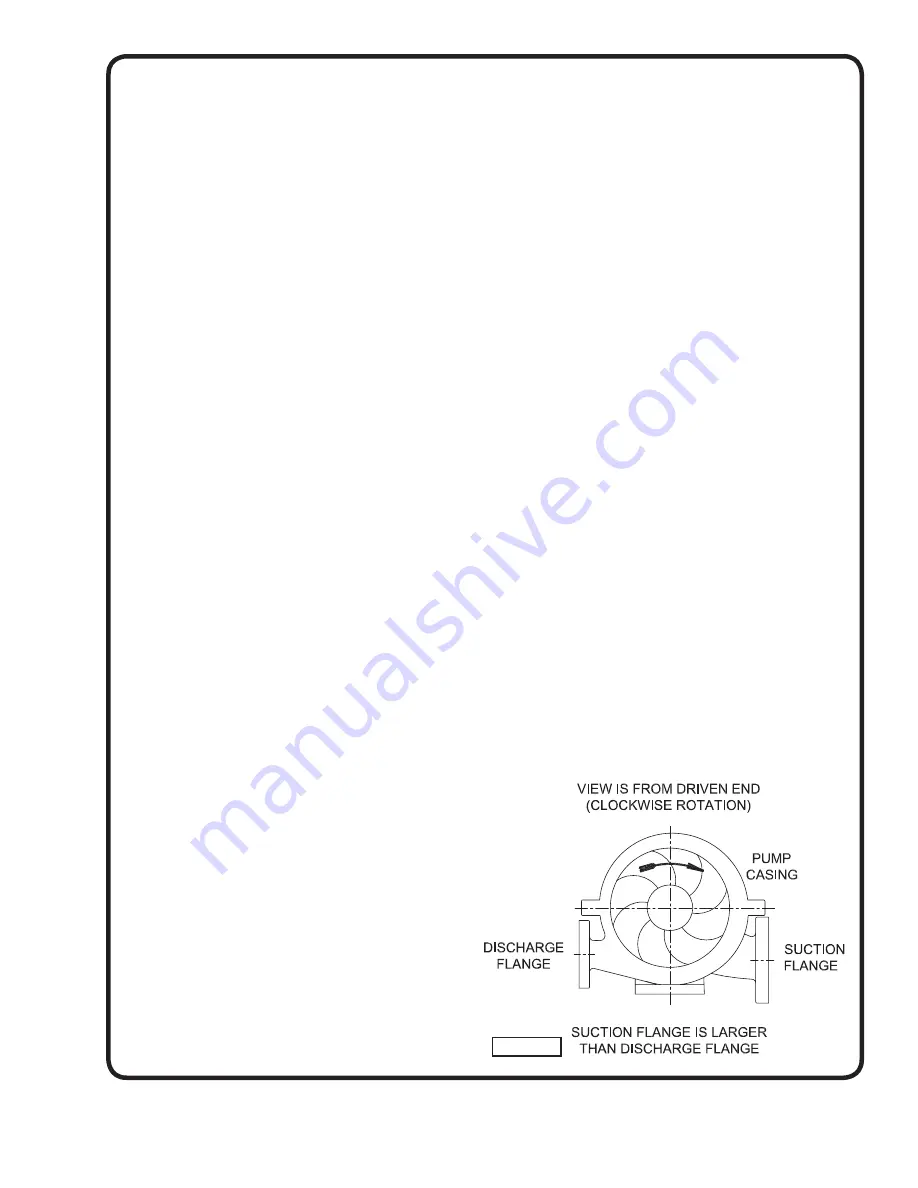

vane curvature as indicated as shown in Figure 4.

Figure 4

Summary of Contents for Deming 5260 Series

Page 7: ...7 Figure 3 ...

Page 22: ...Notes ...