BOILER CONTROLS

The Quinta Ace range can be controlled using a number of

methods – other examples are given below. Scheduling using

the integral Mk3 controller in conjunction with the recommended

Outside / Room sensor when connected to the CB-01 control

board. Other examples are given below. Please contact our

sales or technical departments for further options.

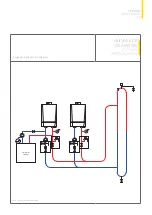

MODULATING (TWO WIRE CONTROL)

When using the optional Remeha compensating controllers the

heat output modulates between the minimum and maximum

value on the basis of the boiler flow temperature sensor. This

applies to both single and multiple boiler installations, under the

dictates of a room and/or outside temperature sensor.

iSense Pro

– multi-boiler multi zone optimising/compensating

controller can control up to ten boilers, two heating zones either

VT or CT and one domestic hot water circuit. Information on

the iSense Pro controller can be obtained from the installation

manual and the suggested wiring and controls schematics for

the controller.

Also, can be used as a boiler sequencer with a 0-10V dc

analogue input signal from a remote BMS controller. Managing

a primary or secondary heating circuit with up to 10 boilers.

The control is temperature dependent only i.e. 5V = 50°C flow

temperature providing lead / lag control, subject to the settings

within the controller.

iSense controller

– single-boiler (option for multiple boiler)

single zone optimising/compensating controller.

Remeha MC4

– in conjunction with the iSense controller can

provide step control for multi-boiler installation of up to four boilers.

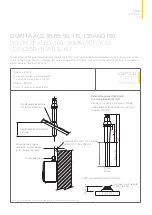

ON/OFF VOLT FREE CONTROL FROM A THIRD

PARTY INSTALLER

Connect a two-wire cable to terminal OT / On-Off which must be

a volt free connection from the third party controller.

Analogue control (0-10V dc)

The heat output modulates between the minimum and the

maximum values on the basis of the voltage supplied by an

external analogue (0-10V) input.

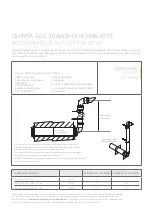

ANALOGUE OUTPUT – TEMPERATURE CONTROL

The 0-10V signal controls the boiler flow temperature between

0°C and 100°C. This control modulates based on the flow

temperature, whereby the heat output varies between the

minimum and maximum values based on the flow temperature

set point calculated by the controller sent by the BMS e.g: 6.4V =

64ºC. A jumper 2 (see table opposite) on the interface is used to

select either temperature control or heat output control (%).

ANALOGUE OUTPUT – CAPACITY CONTROL (%)

The 0-10V signal controls the boiler output between 0% and 100%

of its total capacity (kW). The minimum and maximum values are

limited. The minimum output is linked to the boiler’s modulation

depth. The output varies between the minimum and maximum

value on the basis of the value determined by the controller.

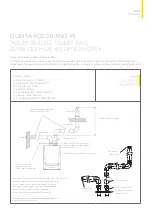

SYSTEM / SHUNT PUMP

A shunt pump can be connected to the boiler via the integral

CB – 01 PCB (maximum input 300VA). If the pump requires more

than this, terminals can only be used to switch a pump relay. The

pump should be fitted on the heating return connection and be

as close to the boiler as possible. A system pump can also be

connected to the boiler via the integral SCB-01 (refer to page 24,

SCB-01 Relay Load data for maximum load).

SYSTEM WATER

Before operation, the system should be cleaned and flushed

(according to BS 7593 (2006) and filled with mains cold water.

Suitable chemicals and their use should be discussed with

specialist water treatment companies in respect to aluminium

heat exchangers. For further information “Remeha Water Quality

Regulations” is available from

remeha.co.uk

The recommendations in the document must be followed.

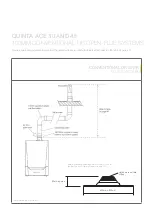

FROST PROTECTION

Install the boiler in a frost-free room. The built-in frost protection

system is activated as follows: below 7°C – system pump is

switched on if connected to the boiler. Below 3°C – boiler is

switched on, when the flow temp reaches 10°C the boiler and

pump switch off. Note: This control is designed to protect the

boiler – for full system protection use a frost thermostat or a

weather compensator.

REMOTE ALARM AND BOILER RUN INDICATION

As standard the boiler is supplied with the integral smart control

board SCB-01. This has two potential-free contacts, Status

/ Function can be configured as required. Depending on the

setting, a common alarm and boiler run signal can be transmitted

by the boiler.

SAFETY INTERLOCKS

As standard the boiler is supplied with shutdown (BL) and

release (RL) inputs via the main standard connections board

CB-01.

JUMPER 2

INPUT

SIGNAL (V)

TEMPERATURE A

DESCRIPTION

0-1.5

0-15

Boiler off

1.5-1.8

15-18

Hysteresis

1.8-10

18-100

Temp required

JUMPER 2

INPUT

SIGNAL (V)

HEAT OUTPUT (%) DESCRIPTION

0-2.0

(1)

0-20

Boiler off

2.0-2.2

(1)

20-22

Hysteresis

2.0-10

(1)

20-100

Heat output

requested

%

(1) Dependent on the minimum modulation depth (set speeds, standard 20%).

29

ELECTRICAL INSTALLATION

AND BOILER CONTROLS

Summary of Contents for Quinta Ace 115

Page 1: ...QUINTA ACE RANGE ...

Page 70: ......