61

FLUECADE DATA

AND CASCADE OPTIONS

CASCADE

OPTIONS

Spreading the total required heat output over several boilers

in cascade configuration offers several advantages:

•

greater reliability

•

higher efficiency

•

improved design flexibility

•

quick and easy installation.

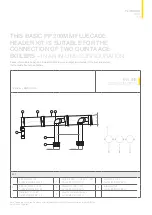

In order to make it as simple as possible to create a cascade

configuration, we have offered complete cascade systems

for years. The compact design of the boilers, combined with the

smart gas and water connection technology of the cascade system,

makes it possible to install a high heat output in a small area.

When installing two to eight boilers, our product range includes

systems that are very comprehensive and easy to install. The

hydraulic and gas system can be put together entirely without

welding, using screw connections, compression connections

and flanges. The individual components of the cascade systems

are available for independent cascade installation.

Please contact our technical or sales departments for different

configurations. We also provide in-depth advice on the choice

of flue gas discharge material and control engineering.

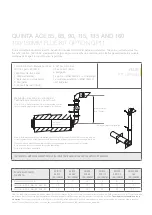

STRUCTURE OF QUINTA ACE

30, 45, 55, 65, 90, 115, 135 AND 160

CASCADE SYSTEMS

The flow, return and gas connections of the individual boilers

are connected using the fittings supplied by means of horizontal

connections to main pipes for flow, return and gas. These pipes

are welded onto a frame that rests on the floor and is fixed to the

wall or to a free-standing frame. The low loss header supplied

has flange connections, which can be fitted to the left or right of

the cascade main pipe as required. The blind flanges supplied

are then fitted on the other side. The gas main pipe has a flange

to which the optional gas filter can also be connected on the

left or right as required. The blind flange supplied is then fitted

on the other side. When a gas filter is used, a pressure loss of

three mbar over the gas filter must be taken into account. The

minimum inlet working gas pressure after the gas filter is 17mbar.

A common PVC condensed water discharge pipe (not supplied)

can be installed in the frame. For this purpose, holes have been

made in the frame into which this pipe can be fitted (to the left or

right as required) sloping downwards.

Quinta Ace 30, 45, 55, 65, 90 and 115 boilers are particularly

suitable for use in cascade systems due to their small footprint

and width of only 50cm which allows an exceptionally compact

cascade configuration. For example, when using six Quinta Ace

115 boilers in line (including low loss header), approximately

only 3.8m wall width is required for 642kW (80/60°C).

The cascade systems can be divided into three main groups:

•

two to seven Quinta Ace boilers in a linear configuration,

wall-mounted

•

two to seven Quinta Ace boilers in a linear configuration,

mounted on a free-standing frame

•

three to ten (2 x 5) Quinta Ace boilers in a back-to-back

configuration, mounted on a free-standing frame. The boiler

side of the cascade systems is sized to 20ºC. The low loss

header or air dirt separator is based on 20/11ºC.

A cascade up to a heat output of 460kW (80/60) has main

flow and return pipes of DN65 and the gas pipe is DN50

with corresponding flanged connections. A cascade up to a

heat output of 830kW (80/60) has main flow and return pipes

of DN100 and the gas pipe is DN65 with corresponding

flanged connections.

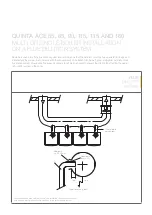

The Quinta Ace 135 and 160 boilers are particularly suitable for

use in cascade systems due to their small footprint and width

of only 60cm which allows an exceptionally compact cascade

configuration. This combined with the smart gas and water

connection technology (no brazing) of the cascade system makes

it possible to install a high output system in a small area. For

example, eight Quinta Ace 160 boilers can be installed in an area

of 4.4m² (including low loss header) to provide close to 1200kW

(80/60°C). It is also possible to have a mixed cascade that

includes the smaller Quinta Ace boilers into the configuration.

The cascade systems can be divided into two main groups:

•

two to eight Quinta Ace boilers in a linear configuration,

mounted on a free-standing frame

or

•

three to eight (2 x 4) Quinta Ace boilers in a back-to-back

configuration, mounted on a free-standing frame. The boiler

side of the cascade systems is sized to 20ºC.

The low loss header or air dirt separator is based on 20/11ºC.

The cascade is supplied with main flow and return pipes of

DN100 and the gas pipe is DN65 with corresponding

flanged connections.

Summary of Contents for Quinta Ace 115

Page 1: ...QUINTA ACE RANGE ...

Page 70: ......