24

CONFIGURING CHECKMATE™ DL WITH RDC CONFIGURATION

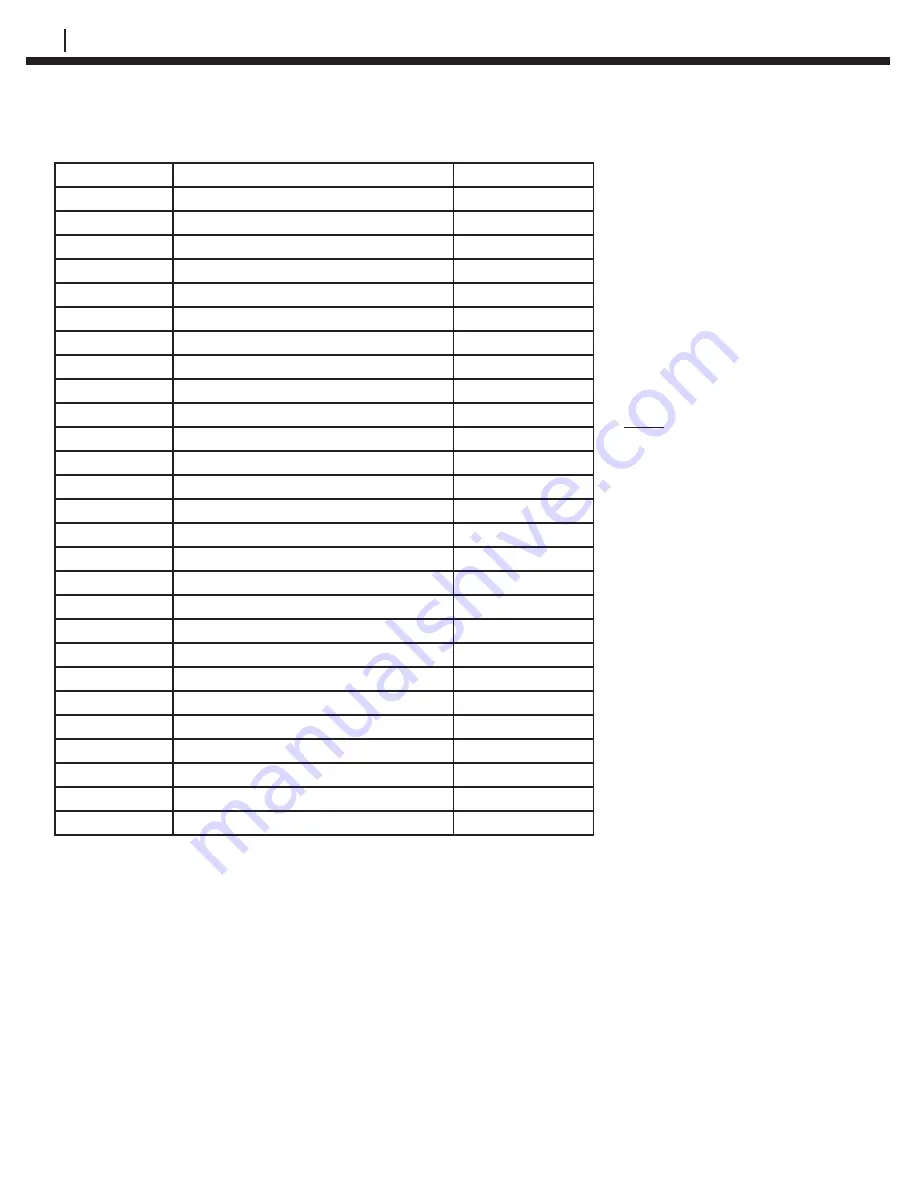

Note: These factors are

recommended for the

MULTIPLIER values. They are

based on use of CORRATER

electrodes which have surface

areas of 5cm

2

for “standard”

probes and 0.5 cm

2

for “

fl

ush”

probes.

UNS Code

Material

Multiplier

K03005

Pipe Grade Carbon Steel

1.00

A91100

Aluminum 1100-0

0.94

A92024

Aluminum 2024

0.88

C11000

Copper 110 ETP Comm. Pure

2.00

C44300

CDA 443 Arsenical Admiralty

1.67

C44500

CDA 445 Phosphorized Adm.

1.68

C64200

CDA 642 A1 Silicon Bronze

1.48

C68700

CDA 687 Alum. Brass Arsenical

1.62

C70610

CDA 706 90/10 Copper/Nickel

1.80

C71500

CDA 715 70/30 Copper/Nickel

1.50

G41300

AISI 4130 Alloy Steel

1.00

L50045

Lead

2.57

N04400

Monel 400 Nickel

1.13

N05500

Monel K-500 Nickel

1.04

N06022

Hastelloy C22

0.85

N06600

Inconel 600 Nickel

0.95

N08020

Carpenter 20 CB3 SST

0.98

N08800

Incolloy 800

0.89

N08825

Incolloy 825

0.88

N10276

Hastelloy C276

0.86

R50400

ASTM B-348 Grades 2-4 Titanium

0.75

S30400

AISI 304 Stainless Steel

0.89

S31600

AISI 316 Stainless Steel

0.90

S31603

AISI 316L Stainless Steel

0.90

S31803

2205 Duplex Stainless Steel

0.89

S32750

2507 Duplex Stainless Steel

0.88

Z17001

Grades 1A, 1, 2, 3, or 5 Zinc

1.29

Table 5.2

Alloy Multipliers

Summary of Contents for Checkmate DL

Page 6: ...iv TABLE OF CONTENTS ...

Page 8: ...ii FIGURES AND TABLES ...

Page 10: ...2 INTRODUCTION Figure 1 2 Checkmate DL Instrument Specifications ...

Page 18: ...10 BASICS OF CHECKMATE DL ...

Page 22: ...14 INITIALIZING CHECKMATE DL TO WORK WITH CORRDATA SYSTEM ...

Page 40: ...32 CONFIGURING A RDC ER 210 USING CHECKMATE DL ...

Page 46: ...38 READING A RDC ER 210 WITH THE CHECKMATE DL ...

Page 52: ...44 TRANSFERRING RDC ER 210 DATA TO THE PC ...

Page 60: ...52 READING A DATA LOGGER WITH THE CHECKMATE DL ...

Page 64: ...56 TRANSFERRING DATA LOGGER DATA TO THE PC ...

Page 66: ...58 TROUBLESHOOTING GUIDE ...

Page 67: ...CHECKMATE DL 59 ...

Page 68: ...60 ...

Page 69: ...CHECKMATE DL 61 ...

Page 70: ...62 ...