Less than 90% of the relief valve set point pressure.

Less than the maximum operating pressure of the

compressor.

Midpoint of the pressure switch range.

5.

Vibration Switch:

Shuts down the unit if vibration

becomes excessive. Recommended for units mounted

to a portable skid.

1.9 Compressor Cooling

This compressor has a water-cooled head and cylinder.

There is one water inlet connection on the cylinder and

two water outlet connections on the head. The owner

of the compressor is responsible for the inlet and

outlet water connections.

The cylinder has one water jacket while the head has

three water jackets. See Figure 1.9 for details.

when installation is complete. Always check the flywheel

runout before startup and readjust if it exceeds the value

listed in Appendix B.

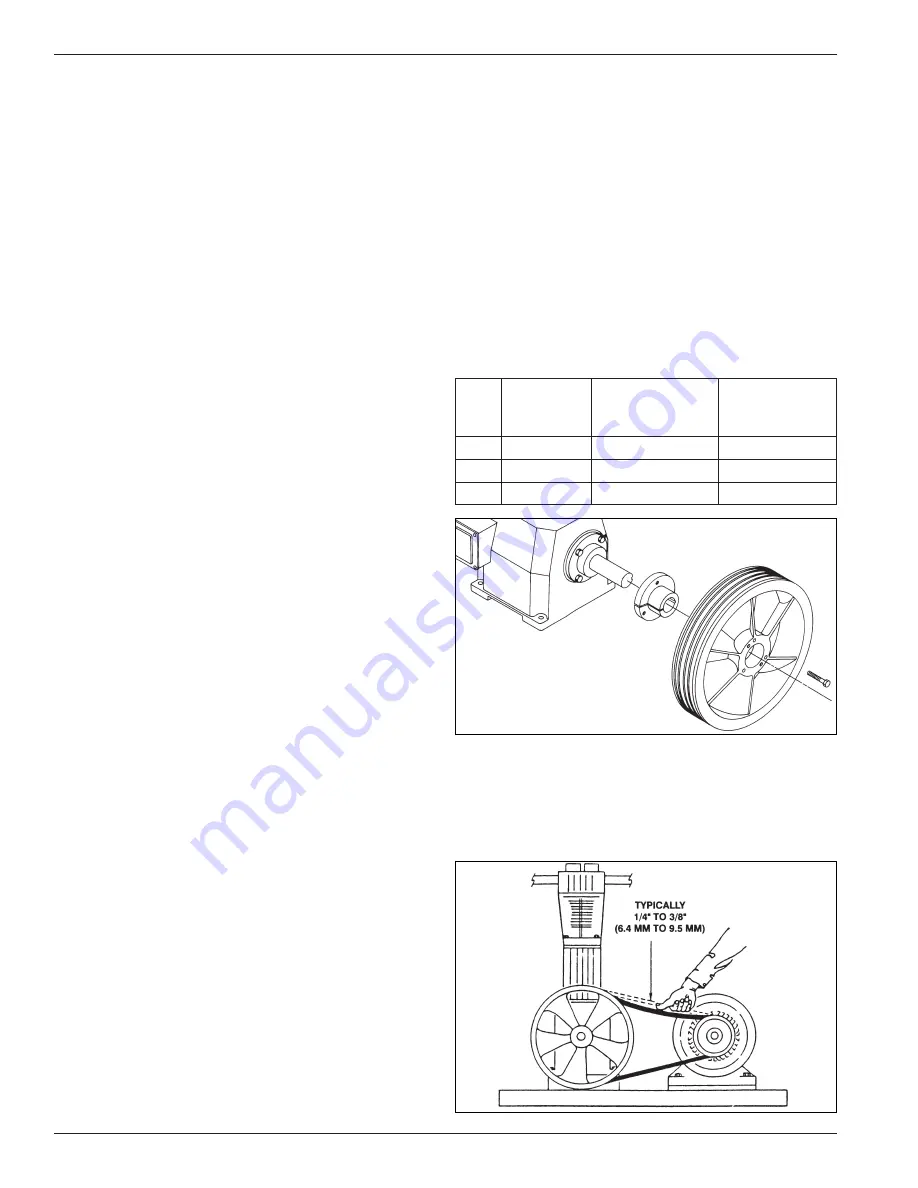

Hub

Size

Diameter

in. (cm)

Bolt Torque

Ft-lb (kg-meter)

Set Screw

Torque Ft-lb

(kg-meter)

SF

4.625 (11.7)

12-18 (1.7–2.5)

22 (3.1)

E

6.0 (15.2)

30-36 (4.1–4.9)

22 (3.1)

J

7.25 (18.4)

75-81 (10.3–11.1)

109 (15.1)

Figure 2.2A: Flywheel installation

Tighten the belts so that they are taut, but not extremely

tight. Consult your V-belt supplier for specific tension

recommendations. Belts that are too tight may cause

premature bearing failure. Refer to figure 2.2B.

Figure 2.2B: Belt tension

NOTE: Read this entire chapter, then proceed with

the startup checklist.

2.1 Inspection After Extended

Storage

If your compressor has been out of service for a long

period of time, you should verify that the cylinder bore

and valve areas are free of rust and other debris. For

valve and/or cylinder head removal instructions, refer to

chapter 4 of this IOM manual.

Drain the oil from the crankcase and remove the

nameplate and crankcase inspection plate. Inspect the

running gear for signs of rust and clean or replace parts

as necessary. Replace the crankcase inspection plate

and fill crankcase with the appropriate lubricant through

the nameplate inspection opening. Squirt oil on the

crossheads and rotate the crankshaft by hand to ensure

that all bearing surfaces are coated with oil.

Rotate unit manually to ensure running gear functions

properly. Replace nameplate and proceed with startup.

2.2 Flywheel and V-belt Alignment

Before working on the drive assembly, be sure that the

electric power is disconnected. When installing new belts,

always make sure the driver and compressor are close

enough together to avoid forcing the belt onto the flywheel.

Improper belt tension and sheave alignment can cause

vibration, excessive belt wear and premature bearing

failures. Before operating your compressor, check alignment

of the V-grooves of the compressor flywheel and driver

sheave. Visual inspection often will indicate if the belts are

properly aligned, but use of a square is the best method.

The flywheel is mounted on the shaft via a split, tapered

bushing and three bolts (see figure 2.2A). These bolts

should be tightened in an even and progressive manner

to the specified torque by the manufacturer. There must

be a gap between the bushing flange and the flywheel

Chapter 2—Starting Up Your Corken Compressor

10