Cooper Crouse-Hinds GmbH

11

11

11

11

11

2

Safety instructions

The safety switches are not

suitable for Zone 0 and Zone 20

hazardous areas.

The temperature class and explosion

group marked on the apparatus shall be

observed.

To ensure adherence to the temperature

class stated on the type label of the

apparatus, the permissible ambient

temperature, the rated terminal cross

section and the self-heating of the

apparatus, that is mainly due to the power

dissipation, shall be taken into account

(test criterion for the self-heating is an

overload of 10%).

Modifications or changes to the safety

switches are not permitted.

They shall be used for their intended

purpose and in a perfect and clean state.

The apparatus shall not be used in dust

layers > 50mm acc. to EN 50 281-1-2.

Only original CCH / CEAG parts may be

used as replacements and for repairs.

Explosion-protected safety switches for variable

frequency drives, 20A - 180A

Repairs that affect the explosion

protection may only be carried out by

CCH / CEAG or by a qualified electrician in

compliance with the respective national

regulations.

Prior to being put into operation, the

control units shall be checked in acc. with

the instructions as per section 6.

Before initial operation, any foreign matter

shall be removed from the apparatus.

Warning:

The covers of the safety switches can only

be removed when the switch is in the “ON”

position.

The safety switches can be switched off

only after having „unlocked“ the

interlocking switch.

Attention!

When opening the interlocking switch, the

drive is switched off.

The national safety rules and regulations

for the prevention of accidents, as well as

the safety instructions included in these

operating instructions, that, like this text,

are set in italics, shall be observed!

3

Conformity with standards

The safety switches meet the requirements of

EN 50 014, EN 50 018, EN 50 019, EN 50 020

and EN 50 281-1-1 (comparable international

standards IEC 60079-0, IEC 60079-1,

IEC 60079-7, IEC 60079-11, IEC 60079-14).

94/9 EC: Equipment and protective systems

intended for use in potentially explosive

atmospheres.

The safety switches fulfil further requirements,

such as those of the EC directive on

electromagnetic compatibility (89/336/EEC).

They have been designed, manufactured and

tested according to the state of the art and to

DIN EN ISO 9001.

4

Field of application

The safety switches are intended for use in

potentially explosive atmospheres in Zones 1

and 2 as well as in Zones 21 and 22 in

accordance with IEC 60079-10.

The enclosure materials used, including any

external metal parts, are high quality materials

that ensure a corrosion resistance and

resistance to chemical substances according

to the requirements for use in a “normal

industrial atmosphere”:

- glass-fibre reinforced polyester

- impact resistant polyamide

- special steel AISI 316 L.

When used in extremely aggressive

atmospheres, the additional data relating to

the chemical resistance of the plastics being

used shall be taken from the data sheet

GHG 902 4001 P0001.

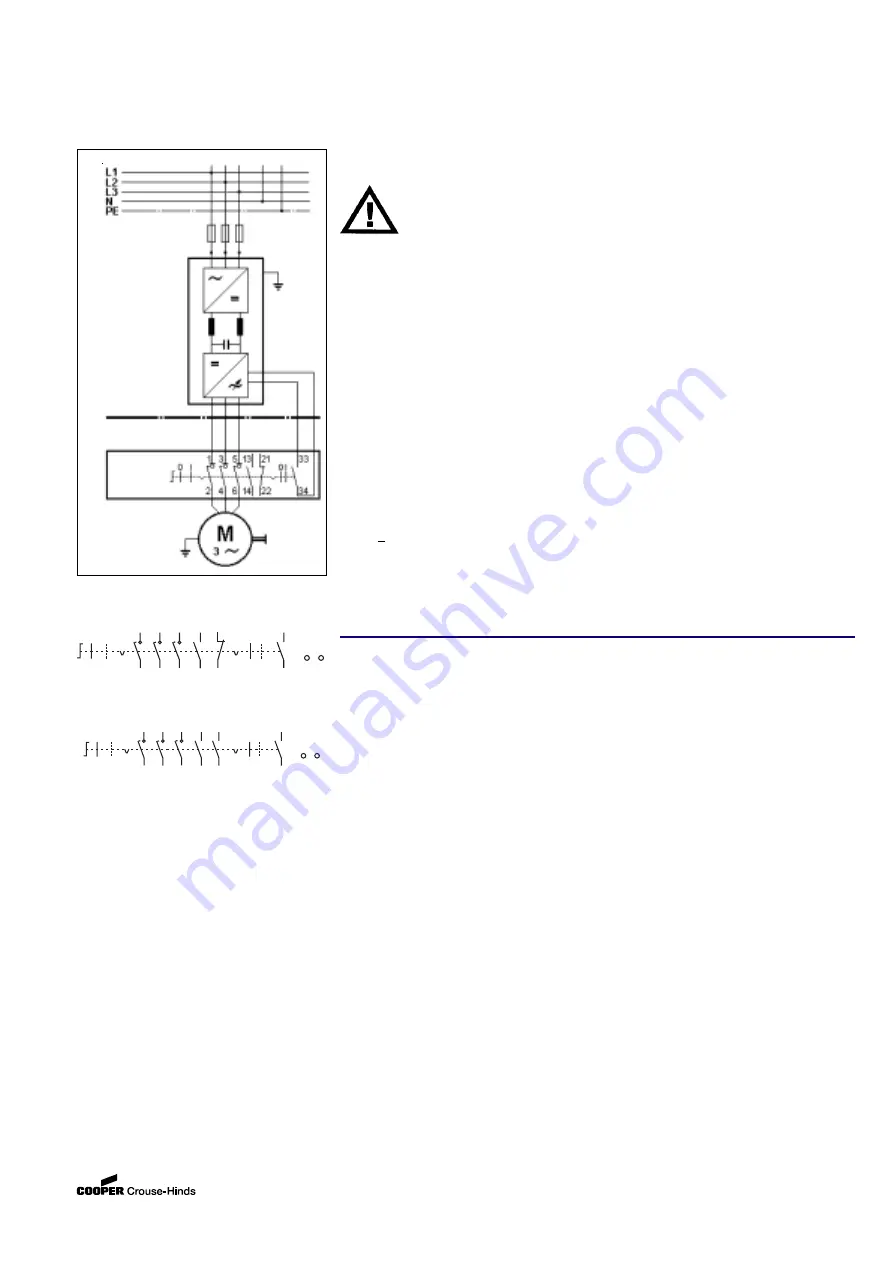

Fig. 5

Ex

Area

Non - Ex

Area

Safety switch

Wiring diagrams

3-pole + 1NO + 1NC

3-pole + 2 NO

5

Application / Properties

The safety switches for variable speed drives

are used for the safe, all-pole isolation of

electrical power when maintenance, cleaning

and repair work is carried out on systems,

machinery and drives operating on frequency-

controlled converter drives in hazardous areas.

See technical data for the temperature class,

explosion group and permissible ambient

temperature.

With frequencies up to f 40 Hz and from

about 60 to max. 200 Hz, the main switch must

be switched without load to avoid damages.

Any damage to the switch within the lower

frequency range (zero point erasing) as well as

within the upper frequency range (restriking) is

thus prevented.

The time delay required for switching off the

converter (approx. 1 second) is achieved by

means of a compulsory mechanical

interlocking auxiliary switch. See also

functional diagram, Fig. 1 and Fig. 2, page 9.

Due to the compulsory mechanical

interlocking, a maloperation of the switch is

not possible without destroying it.

In addition to this, the safety switches are

fitted with auxiliary contacts (1 N/O and 1 N/C),

that, in relation to the main contacts, are

lagging / leading during making and leading /

lagging during breaking.

0 I

30° 90°

1

2

5

3

13

4

6

14

N PE

22

21

0 I

33

34

0 I

30° 90°

1

2

5

3

13

4

6

14

N PE

0 I

33

34

23

24