Cooper Crouse-Hinds GmbH

14

14

14

14

14

6.6

Putting into operation

Before putting the apparatus into operation,

the tests specified in the individual national

regulations shall be performed.

In addition to this, before being put into

operation, the correct functioning of the

apparatus and installation of the apparatus

shall be checked in accordance with these

operating instructions and other applicable

regulations.

The improper operation of safety switches

may result in the invalidation of the

guarantee.

6.5

Closing apparatus

Any foreign matter shall be removed from

the apparatus.

The switch handle on the cover of the switch

is to be set to the "ON" position.

When fitting the apparatus cover, care shall

be taken to ensure that the switch shaft of

the switch insert engages correctly in the

carrier hole of the switch handle.

To ensure the required minimum degree of

protection, the cover screws shall be

tightened down.

Overtightening may impair the degree of

protection.

7

Maintenance / Servicing

The valid national regulations for the

servicing / maintenance of electrical

apparatus for use in potentially explosive

atmospheres shall be observed (e.g. ElexV,

VDE 0105, Part 9 in Germany).

Prior to opening the enclosure, it is

necessary to ensure that the voltage supply

has been isolated or to take suitable

protective measures.

The necessary intervals between servicing

depend upon the specific application and

shall be stipulated by the operator according

to the respective operating conditions.

During servicing, special attention shall be

given to checking the parts on which the

explosion protection depends (e.g. intactness

of the flameproof components, the enclosure,

the seals and cable entries).

Special attention shall be given to the safe

functioning of the cover interlock and the

perfect condition of the locking device.

If, in the course of servicing, it is ascertained

that repairs are necessary, section 8 of these

operating instructions shall be observed.

8

Repairs / Overhaul /

Modifications

Modifications

Modifications

Modifications

Modifications

Only original CCH / CEAG parts shall be

used for carrying out repairs.

In the event of damage to the flameproof

encapsulation, replacement of these

components is mandatory. In case of

doubt, the respective apparatus shall be

sent to CCH / CEAG for repair.

Repairs that affect the explosion protection

may only be carried out by CCH / CEAG or

by a qualified electrician in compliance

with the respective national regulations.

Apparatus modifications or design changes

are not permitted; excepted from this is the

fitting of additional cable entries within the

scope of the apparatus approvals.

9

Disposal / Recycling

The respective valid national regulations for

waste disposal shall be observed when

disposing of apparatus.

To facilitate the recycling of individual parts,

parts made of moulded plastic shall bear the

marking for the type of plastic used.

The product range is subject to changes and

additions.

Explosion-protected safety switches for variable

frequency drives, 20A - 180A

The unused entry hole of the double cable

end box is to be closed with a sealing sleeve,

item 5 (order No. GHG 740 1933 R0003).

Attention: In order to ensure that the

required minimum protection category is

maintained, it is necessary ensure that the

seal, item 6, is in the correct position.

When using cable entries with a lower IP

protection than that which applies to the

device (see technical data, page 9 and 10),

the IP protection of the complete unit is

reduced.

Intrinsically safe circuits shall be fed through

cable entries that are colour-coded (light blue).

In order to ensure the minimum degree of

protection, any unused entry holes shall be

sealed with certified blanking plugs.

When fitting cable entries, care has to be

taken that the sealing inserts are suitable for

the cable diameter.

In the case of sealing inserts that have to be cut

to size, it is necessary to ensure that the insert

is properly adapted to the cable diameter.

When using cable entries for fixed cables it is

necessary to ensure that no inadmissible high

mechanical stress is applied to the cable entry

or its seal.

In order to ensure the required minimum

degree of protection, the cable entries shall be

tightened down securely.

Overtightening can impair the degree of

protection.

Warning: When tightening the cap nut of

the metal cable entry (e.g. type E1WF/e),a

suitable tool shall be used to safeguard the

gland against twisting.

Any unused metric CCH / CEAG cable

entries shall be sealed with the blanking plug

certified for these metric cable entries.

6.4

Flanges, metal plates and

external earth connection *

If flange plates have to be dismantled, (e.g. to

drill entry holes), when replacing the plates, in

order to maintain the minimum degree of

protection, it is necessary to ensure that the

flange plate and the fixing clamp fit correctly.

PE conductors fed from outside shall be

connected to the PE terminal provided on

the flange.

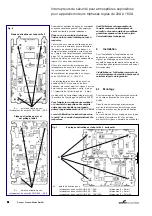

In case an external earth connection is mounted

on the plastic enclosure, it should be connected

with a max. 25mm² wire.

This earth connection is inserted through a M6

drill in the inner wall of the enclosure (see fig.

10).

Warning: Metal flanges, metal plates and

metal glands shall be incorporated in the

potential equalization.

*

not yet certified for category II D

Fig. 10

External earth connection

Inner wall of

the enclosure

Internal

earth plate

Internal earth

connection