TECP-90-814 • Rev C • October 2020

Page 16

© 2020

CommScope

. All Rights Reserved.

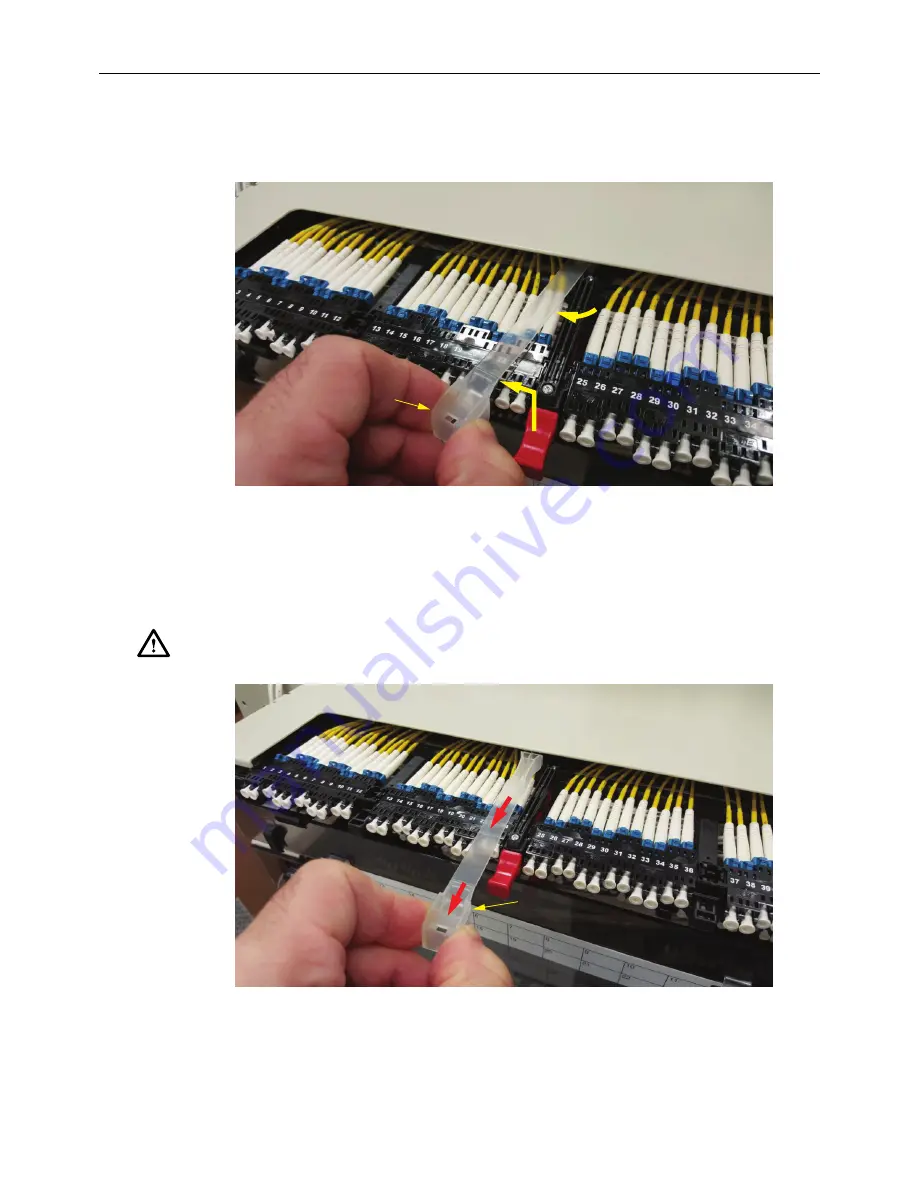

3. Withdraw the latch shipping bracket slightly (enough to clear it from the red latch), and

move the shipping bracket to one side, as shown in

Figure 14. Locking Tray Into Payout Position

4. Slide the latch shipping bracket out of the cable spool tray as shown in

and clear

it from the panel, then push the red latch and tray in to operational position.

Figure 15. Removing Latch Shipping Bracket from Tray

Caution:

When removing shipping bracket, use caution to avoid damaging fibers.

26176-A

LATCH

SHIPPING

BRACKET

26177-A

LATCH

SHIPPING

BRACKET