16

17

APEX

APEX

APEX

APEX

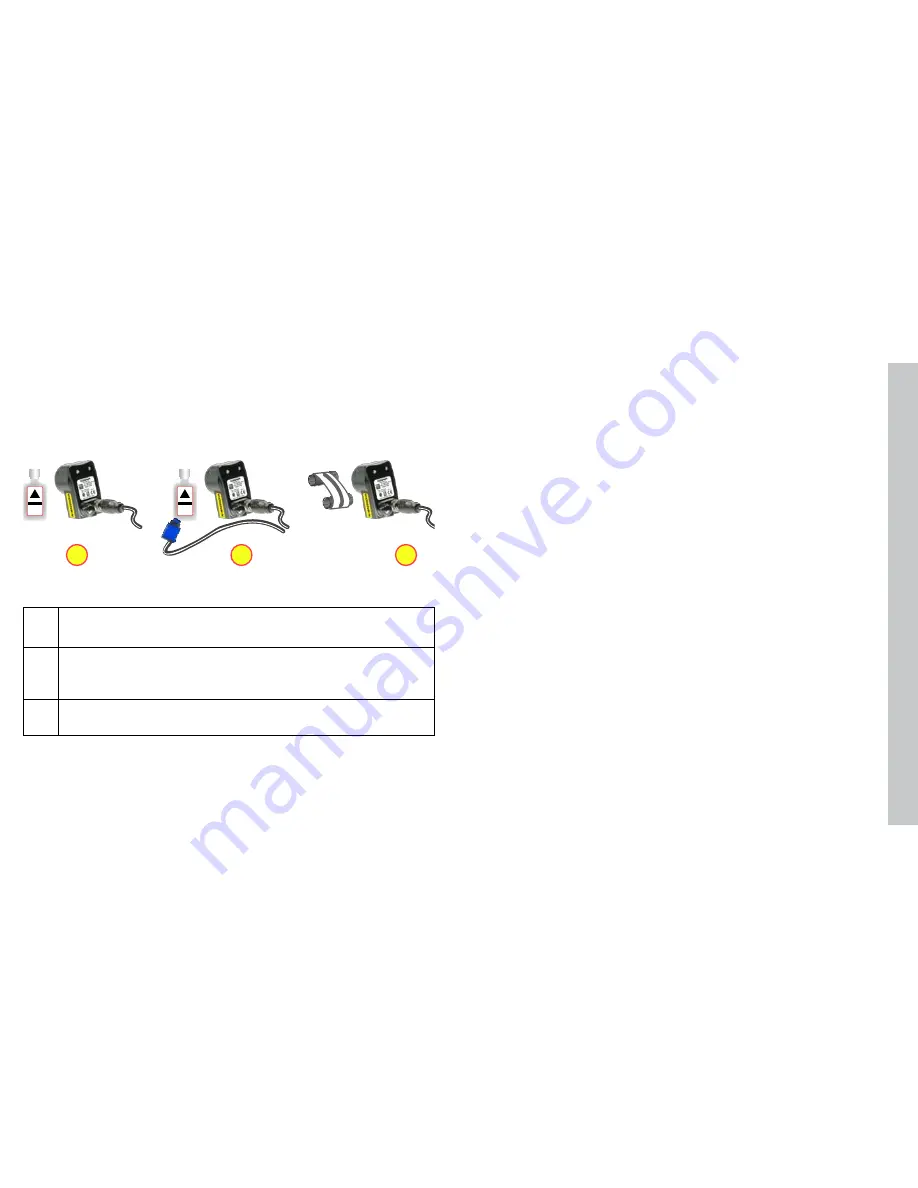

1

2

3

1

Internal Part Trigger

: Checker uses its Part Finding Sensor to detect when a part is

present and ready to be inspected. You create and configure the Part Finding Sensor

by selecting a feature on your part that is always present

2

External Part Trigger

: Checker uses an external signal that your equipment supplies

to detect when a part is present and ready to be inspected You use an External Trigger

by configuring a device such as a photoelectric sensor, contact switch, or proximity

sensor, then connecting it to Checker’s Trigger input line

3

Free Running

: Checker inspects each and every image that it acquires, not just the

images that contain a part or for which an external trigger is received

Checker Part Triggers

A part

trigger

tells Checker that a part is ready to be inspected Checker supports three trigger

types

Choosing a Trigger Type

You set the trigger type in the

Start ►Select Trigger

step on SensorView Teach Pendant or the

Select Part Trigger

step on the PC

In most cases, it is simplest to use the Internal Part Trigger, since no external equipment is

required You create a Part Finding Sensor in the

Set Up Sensors ►Find My Part

step on

SensorView Teach Pendant or the

Find My Part

step on the PC

If the appearance of your parts is highly variable, or if your line already has a device or sensor

that produces a part trigger signal, you can use an External Trigger

Free Running mode is useful for several types of applications:

Checking objects that move continuously and which cannot be detected with a Part Finding

•

sensor, such as a moving web of paper or metal

Checking parts that move in multiple ways, such as a part that moves into the field of view

•

and then rotates in place

Performing continuous inspection of non-moving objects to check for changes in

•

appearance

Summary of Contents for Checker 3G Series

Page 1: ...COGNEX Checker 3G Series User s Guide...

Page 25: ...COGNEX 590 7096...