PULSAR

®

III-P/III-PE and VI-P/VI-PE PRESSURE CABINETS

Page 13

© 2019 CLEMCO INDUSTRIES CORP.

www.clemcoindustries.com

Manual No. 21527, Rev. I, 02/19

4.5.6

Insert hands into gloves.

4.5.7

To blast, firmly grasp the nozzle holder or hose

just behind the nozzle holder, point the nozzle toward

the object to be blasted, and apply pressure to the foot

pedal; blasting will begin almost immediately.

WARNING

Shut the cabinet immediately if dust leaks are

detected from the dust collector or cabinet.

Make sure the dust-collector filter(s) are

correctly seated and not worn or damaged.

Prolonged breathing of any dust can result in

serious lung disease or death. Short-term

ingestion of toxic dust such as lead, poses an

immediate danger to health. Toxicity and health

risks vary with type of media and dust

generated by blasting. Identify all material being

removed by blasting and obtain a safety data

sheet (SDS) for the blast media.

4.5.8

Adjust the pilot pressure regulator to the

required blasting pressure, per Section 5.1. The

regulator is located on the top-left side of the cabinet.

NOTE: Pressure registers on the gauge only while

blasting.

NOTE: When holding parts off the grate, use a solid

conductive backrest to support the part. Without this

assist, especially with longer blasting operations, the

operator will tire easily from resisting blast pressure, and

static electricity could build up in the ungrounded part

and cause static shocks. Whenever possible, avoid

holding small parts that require blasting into the glove.

4.5.9

If an object should fall through the grate, stop

blasting immediately and retrieve it.

NOTICE

To prevent rapid frosting of the view window,

install a view-window cover lens, per Section

7.4, and avoid pointing the blast nozzle toward

the view window

4.6

Operation and Function of the Choke Valve

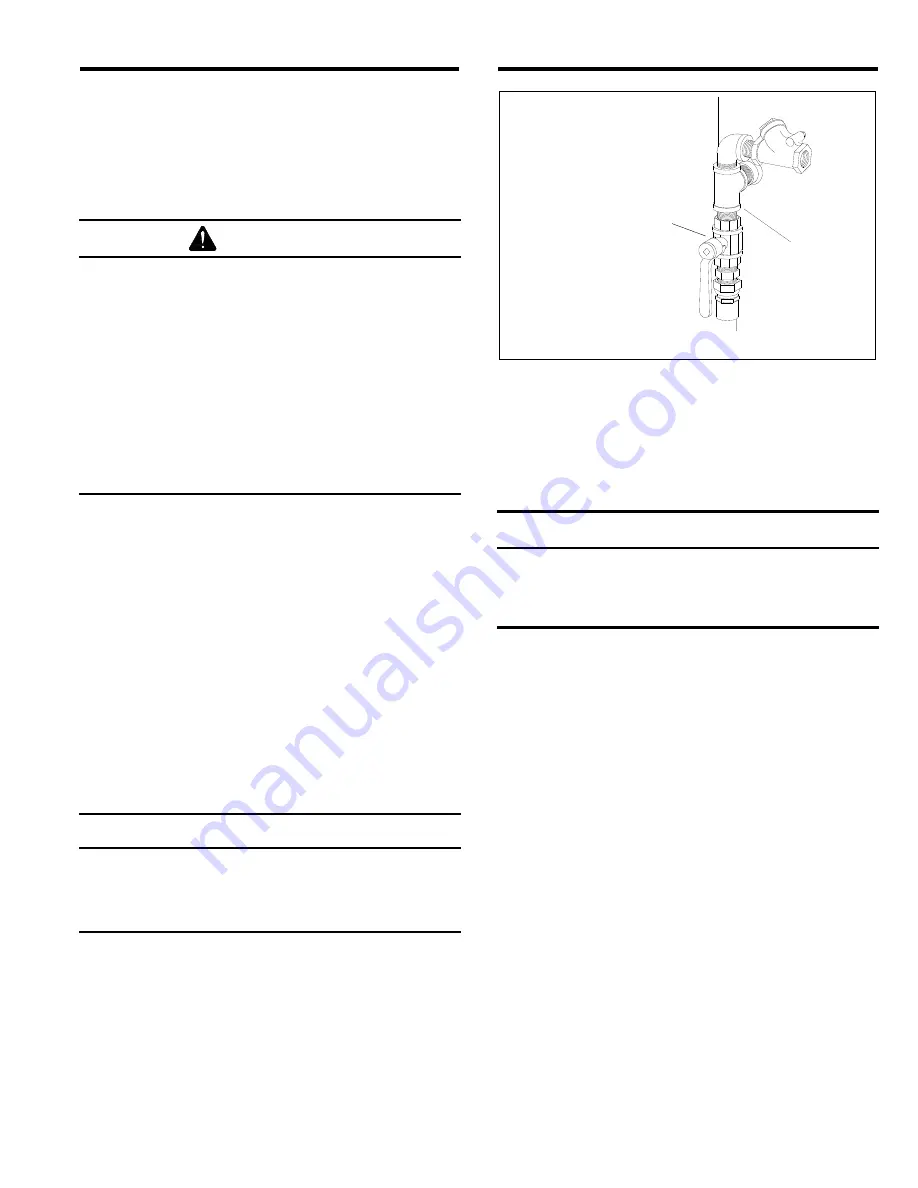

Figure 14

4.6.1

Always fully open the choke valve while blasting;

open is when the handle is vertical and aligned with the

piping, as shown in Figure 14.

Figure 14

4.6.2

Closing the choke valve while blasting lowers

pressure in the pusher line from the pressure in the

vessel. Closing the valve forces media through the

metering valve to clear minor blockage, such as damp

media, or it is used to rapidly empty the machine to

change media.

NOTICE

Do not blast with choke valve closed or partially

closed. Prolonged blasting with the choke valve

partially closed will accelerate wear on the

metering valve.

4.7

Blasting Technique

4.7.1

Blasting technique is similar to spray painting

technique. Smooth, continuous strokes are usually most

effective. The distance from the part affects size of blast

pattern. Under normal conditions, hold the nozzle

approximately 6" from the surface of the part.

4.8

Stop Blasting

4.8.1

To stop blasting, remove pressure from the foot

pedal. The blast machine will depressurize each time the

foot pedal is released.

4.8.2

. The blast machine refills with media stored in

the reclaimer each time the foot pedal is released and

the blast machine depressurizes. Refill takes

approximately 15 seconds when the machine is empty.

4.8.3

Use the blow-off nozzle to blow media off

cleaned parts.

4.8.4

Keep doors closed and exhauster running until

the cabinet is clear of all airborne dust.

Choke Valve

Valve is shown open;

the position of the

handle is aligned with

the piping.