TLR-50 PNEUMATIC REMOTE CONTROLS

Page 3

2.3.2

Band the control handle to the blast hose close

to the nozzle holder, using the two nylon ties provided.

Once the control is firmly attached, clip the tie ends so

they will not snag the operator's clothing or interfere with

the operation of the control handle.

2.4.3

Attach the 25-ft. twinline hose to the two fittings

on the control handle. Either side of the hose can be

attached to either fitting.

2.3.4

Working from the control handle back, band or

tape the twinline hose to the blast hose every four to six

feet, and as close to the couplings as possible.

2.3.5

Make sure the coupling gaskets are in place and

not worn before connecting the blast hose to the quick

coupling on the blast machine. To reduce the risk of

accidental coupling separation when the hose is under

pressure, use safety lock-pins or safety wire to lock the

couplings together.

WARNING

Hose disconnection while under pressure could

cause serious injury or death. Use safety lock-

pins and safety cables on all coupling

connections to help prevent hose couplings

from accidental disconnection.

2.3.6

Screw the two hose unions into the unattached

fittings of the 25-ft. twinline hose.

2.3.7

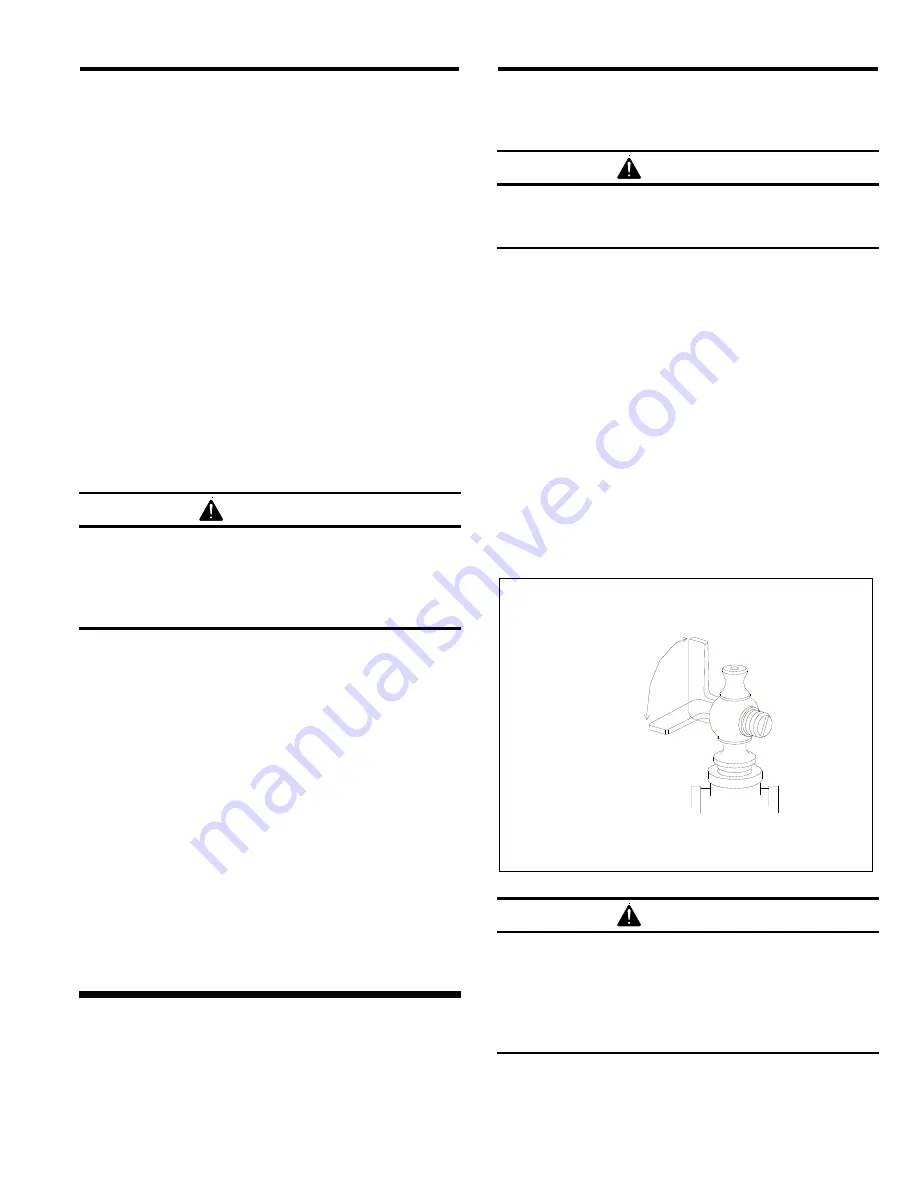

Attach the 3-ft. twinline control hose to the inlet

valve as shown in Figure 1. One side of the hose

connects to the unused upper elbow, the other to the

orifice fitting.

2.3.8

Connect the other end of the 3-ft. twinline to the

hose unions on the 25-ft. twinline. Either side can

connect to either union.

2.3.9

Band the control hoses on the blast machine

side of the unions to the quick coupling nipple.

2.3.10

Make sure that all fittings are tight. Leaks will

cause the system to malfunction.

3.0 OPERATION

WARNING

Refer to the manuals listed in paragraph 1.1.2.

Do not operate this equipment before reading

the instruction manuals for all equipment.

3.1 Start-Up

3.1.1

Make sure that all hose connections are secured

with safety lock-pins and safety cables to prevent

accidental separation or disconnection.

3.1.2

Connect the blast machine to an adequate air

supply. The compressor should be located upwind from

the blasting operation to prevent dust from entering the

compressor intake.

3.1.3

Make sure that the safety petcock located on the

inlet valve is open. The petcock is open when the

petcock lever is in-line with the petcock, as shown if

Figure 2.

Figure

2

Open

Closed

WARNING

To prevent severe injury from accidental

activation of the blast machine, open the safety

petcock when the blast machine is not in use.

Opening the petcock prevents unintentional

blasting. The control handle can not activate

the machine when the petcock is open.