16

Parts & Service: 020 8988 7400 / E-mail: [email protected] or [email protected]

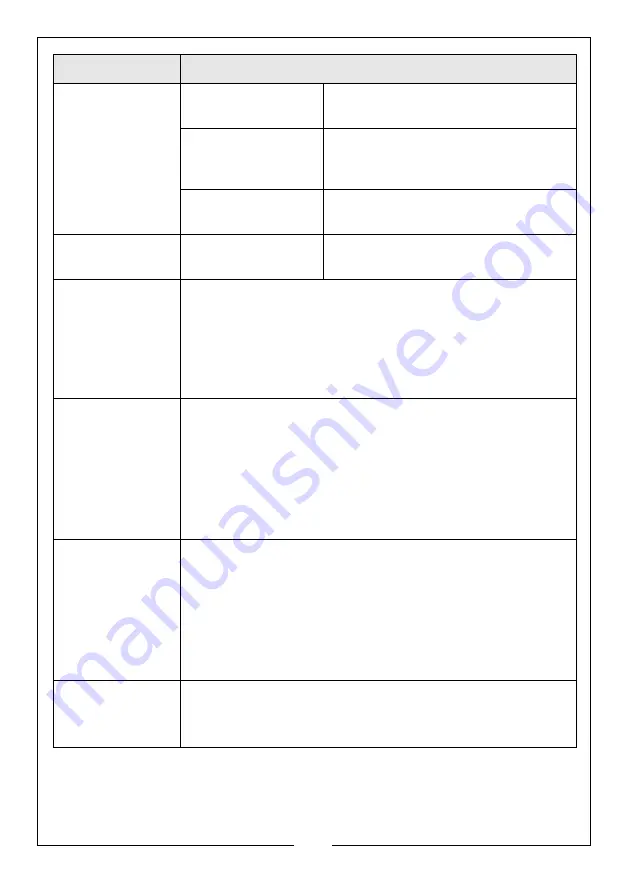

Gas does not

flow

Nozzle blocked.

Clean nozzle and replace if

necessary.

Air pressure

regulator not

sufficiently open.

Ensure regulator is correctly

adjusted.

Blockage in

compressed airline

Check supply hose and the hose

within the cutting torch cable.

Unit continually

overheats

Input voltage too

high or too low.

Have electrician inspect the

building power supply.

Insufficient

penetration

1. Cutting speed too high.

2. Torch is tilted.

3. Workpiece is too thick.

4. Cutting current is too low.

5. Torch parts are worn out.

Interruption of

the cutting arc

1. Cutting speed too slow

2. Excessive distance between torch and workpiece

3. AC line too low - reduce output current

4. Torch parts are worn out

5. Non-genuine manufacturer's parts

6. Work cable is disconnected

Excessive scoria

settlement

1. Too low cutting speed causing bottom dross

2. Too high cutting speed causing top dross

3. Excessive distance between torch and workpiece.

4. Cutting current too low

5. Torch parts are worn out

6. Non-genuine manufacturer's parts

Tilted cutting

1. Torch position not correct

2. Asymmetric wear of nozzle hole and/or wrong assembly

of the torch parts

Problem

Possible Cause and Likely solution

Summary of Contents for 6015700

Page 24: ......