C I R R U S

C O M P O N E N T M A I N T E N A N C E M A N U A L - C A P S

M O D E L S R 2 0

95-01-01

Page 49

Serials 1423 thru 1624 before SB2X-95-18

EFFECTIVITY:

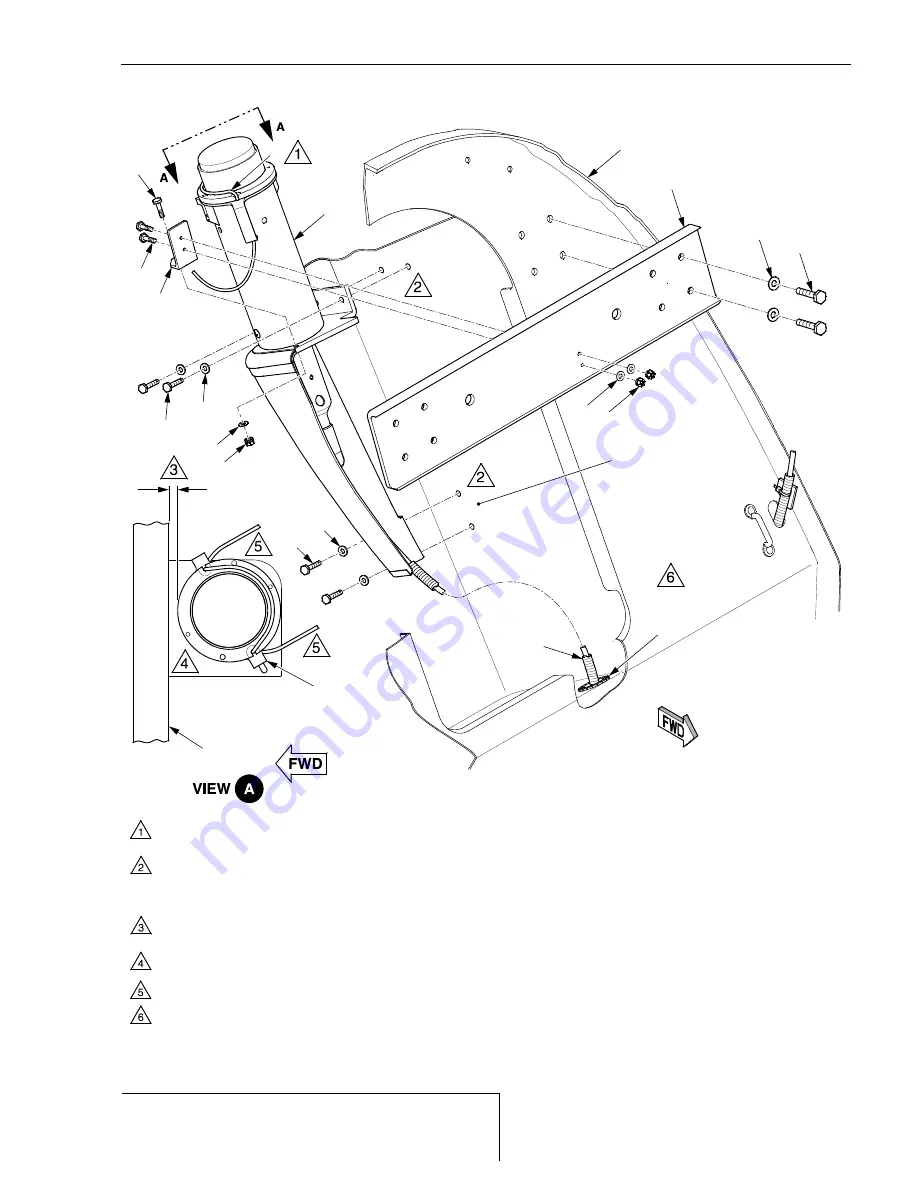

Figure 95-01-0111

Rocket Installation - Serials 1423 thru 1624 before SB2X-95-18 (5 of 10)

6

5

8

Serials 1423 thru 1624 before SB2X-95-18.

1

2

21

1

ADJUSTABLE

BUSHING

(REF)

BH 222

(REF)

2

1

22

2

1

20

2

2

21

1

CAPS COMPARTMENT

(REF)

LEGEND

1. Bolt

2. Washer

5. Rocket Assembly

6. Rocket Lanyard

8. Spiral Wrap

20. Cross Beam

21. Nut

22. Bracket

SR20_CM95_1815E

0.40 inch

(10.16 mm)

BH 222

(REF)

PICK-UP

COLLAR

(REF)

Ensure ends of lanyard routed aft do not wrap around forward portion of rocket assembly.

Position rocket lanyard around top outer diameter of pick-up collar support,

NOT over top of the rocket. Failure to comply will absolutely FAIL rocket deployment!

Due to differing tolerances between the rocket assembly shelves, quantities of shims/washers

may differ from those depicted in the figure. Ensure the exact stackup of the attaching hardware

is noted during disassembly and then replicated during reassembly. Failure to do so may result

in an incorrect rocket installation and subsequent deployment failure.

NOTE

Incorrect gap between outer diameter of pick-up collar and aft side of BH 222 may result in

deployment failure.

To facilitate rocket assembly removal, move CAPS harness to either side and carefully

pull spiral wrap cable from adjustable bushing pass-through hole as required.

Verify LH edge of pick-up collar is oriented away from BH 222.

4 May 2015