Chapter 1 Safety Instructions

Chapter 1 Safety Instructions

CAUTION

It is not advisable to install an electromagnetic contactor in the side of

output power supply, because the operation of open and close to the

contactor when the motor is running may cause damage to the inverter

arising from over-voltage produced during this process. But it is still

necessary to install a contactor if one of the following three points occurs:

1.The system of frequency converting governor used to control energy-

saving usually works at a rated rotation speed. To run the governor

economically, there is a must to remove the inverter.

2.The inverter participates in some import procedure and cannot stop

operating for a long period of time. To realize free shift in various control

systems and improve the reliability of these systems, there is a must to

install a contactor.

3.When an inverter controls several motors, there is a must to install a

contactor.

Caution: DO NOT operate the contactor if there is output of the inverter.

1.5 Cautions for Operation

HAZARD

Do not operate electrical equipment with wet hands.

An inverter stored for a year or longer should be given

powerup test before use so that the main circuit filter capacitor

could be recovered.When the inverter is in the state of powerup,

it is necessary to raise the voltage gradually to the rated value

with a voltage regulator. Generally, the charging time should be

controlled within 1~2 hours. Otherwise, there is the danger of

electric shock or exposure.

Do not touch the inner side of the inverter while the power is

ON, nor put any foreign matter, i.e., rod or other matter inside the

inverter. Otherwise, it may result in serious damage to the

equipment or death to personnel.

Do not open the front cover while the inverter is powered ON.

Otherwise, there is the danger of electric shock.

Be careful to select the Restart Mode. Otherwise, there is

the danger of personnel death.

WARNING

If the inverter runs at a frequency higher than 50Hz, DO confirm

it is within the speed range acceptable by your motor bearing and

mechanical device. Otherwise, there is the danger of damage to the

motor.

It is not advisory to run the reduction box, gear and other

mechanism that need lubricating at low speed for a long period.

Otherwise, it may reduce the service life of these equipment or

even damage the equipment.

A general motor should be derated before use due to less

effective of heat dissipation when it runs at a low frequency. If it is

a constant torque load, then a forced method or a special variable

frequency motor should be used to release heat.

DO cut off the power supply of an inverter set aside for a long

time to avoid foreign matter or other things enter in it which may

cause damage to the inverter or even lead to fire.

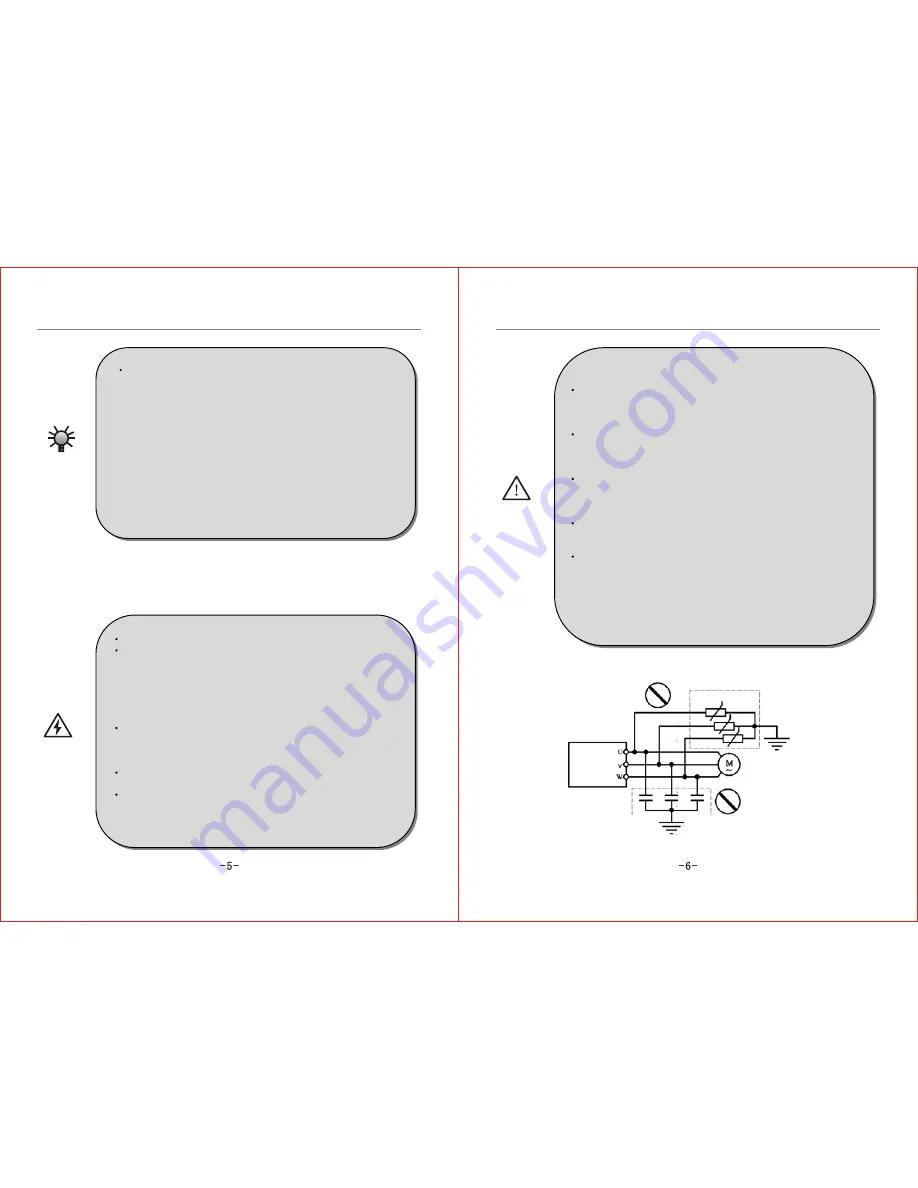

The output voltage of inverter is PWM impulse wave. DO NOT

install a capacitor or surge current sink (i.e., a varistor) in the

inverter output port. Otherwise, there is the danger of fault tripping

of the inverter or damage to its power elements. DO remove such

kind of things if already installed. See the Figure 1-3 below.

Forbidden

Forbidden

Inverter

Power factor

compensation

capacitor

Surge current sink

Figure 1-3

Summary of Contents for ZVF9V-G/P

Page 8: ...M Integration Module S Schism Module...

Page 12: ......

Page 16: ......

Page 21: ...Inverter...

Page 33: ......

Page 87: ......