PMA_CHR_CD40199_R01_allPIXA_SWIR_GigE_User_Manual.docx

10

2.3 Import and export regulations

IMPORTANT

NOTE:

We would like to point out that the cameras described in this manual are

covered by Annex I to EC Regulation No. 2021/821 under ECCN 6A003,

also known as "dual-

use” items. Prior the import, export, transit or

transfer, the exporter shall diligently check on its own responsibility for

any applicable reporting or license requirements, restrictions, and

prohibitions. The import, export, transit, or transfer may be subject to

licensing requirements, or prohibited in accordance with the

aforementioned regulation. We also point out that similar licensing

obligations as well as restrictions or prohibitions may apply outside the

European Union according to the respective export control law and

regulations of the country from where the products shall be exported to or

shall be imported into.

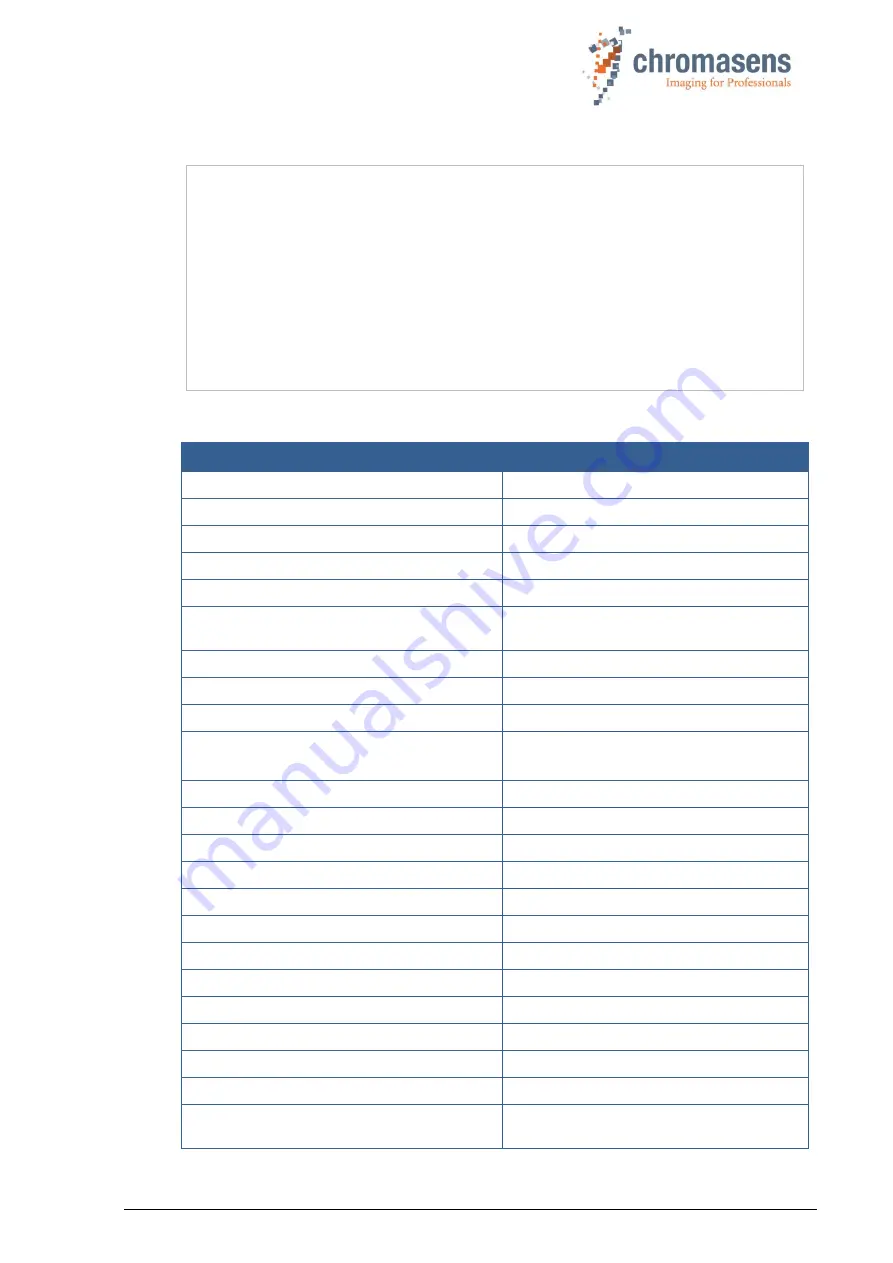

2.4 Technical specification

Sensor

InGaAs short-wave infrared line sensor

Spectral sensitivity

950 nm to 1700 nm

Resolution

1024 px or 512 px

Pixel size

12,5 µm or 25 µm (square)

Pixel bit depth

8 / 10 / 12 bit

Line scan operating mode

Free-running / software trigger /

external trigger

Maximum line frequency

40 kHz

Minimum integration time

21 µs

Interface

GigE Vision (1000BASE-T, RJ-45)

Other interfaces

Power supply (6-pin Hirose, male)

External I/O (12-pin Hirose, male)

Digital input

3x RS422 or LVTTL

Digital output

2x RS422

Lens mount

C-Mount (F-Mount on request)

Protection class

IP40

Conformity

CE, RoHS

Power supply

12 to 24 VDC +/- 10 %; 6 W

Housing dimensions

L = 62 mm, H = 62 mm, D = 52 mm

Weight

170g

Storage temperature

-20 °C to +70 °C; -4 °F to +158 °F

Operating temperature (housing)

-10 °C to +50 °C; +14 °F to +122 °F

Maximum operating temperature mainboard

+100 °C; +212 °C

Maximum operating temperature sensor

+60 °C; +140 °F

Air humidity during operation

10% - 90% relative air humidity,

non-condensing