ChipBLASTER Inc

30

14.0. PREVENTATIVE MAINTENANCE (Cont.):

14.13. Filter Changing procedure General Warnings:

USE CARE WHEN CHANGING FILTER CARTRIDGES

AS THEY MAY BE HEAVY DEPENDING ON

MATERIAL BEING MACHINED. THE USE OF

GLOVES AND SAFETY GLASSES IS STRONGLY RECOMMENDED

DUE TO THE CHIPS THAT MAY BE IN THE FILTERS.

14.14. DUAL MANUAL FILTER: (CHIPBLASTER SHUT DOWN)

The preferred method is to shut down the ChipBLASTER.

14.14.1. A dirty filter error signal to alarm horn/machine center or a 1 bar (15 psi), or

less, pressure reading on the filter outlet pressure gauge will indicate when the

cartridge filter is dirty.

14.14.2. Check gauges to ensure that pressure is relieved from the housing. Then,

remove the filter lid hold-down screws using a 17mm wrench.

14.14.3.

Remove lid and inspect for damage. Be careful not to damage filter hold down

plate, seal or spring. Set lid aside.

14.14.4.

Pull the filter cartridge out of the housing.

14.14.5.

Install the new filter cartridge in the housing. Ensure cartridge it is all the way

down and firmly seated.

14.14.6.

Inspect the lid seal O-ring for cracks or tears, replace if damaged.

14.14.7.

Inspect filter hold down plate, spring and seal. Replace any damaged parts.

14.14.9. Reinstall the filter lid. Make sure the O-ring is in the proper groove before

installing the lid. Set the filter lid straight down so that the filter hold down

plate will properly contact the seal on cartridge filter top.

14.14.10. Torque filter lid cap screws to 41Nm (30 FT LB) in a star pattern.

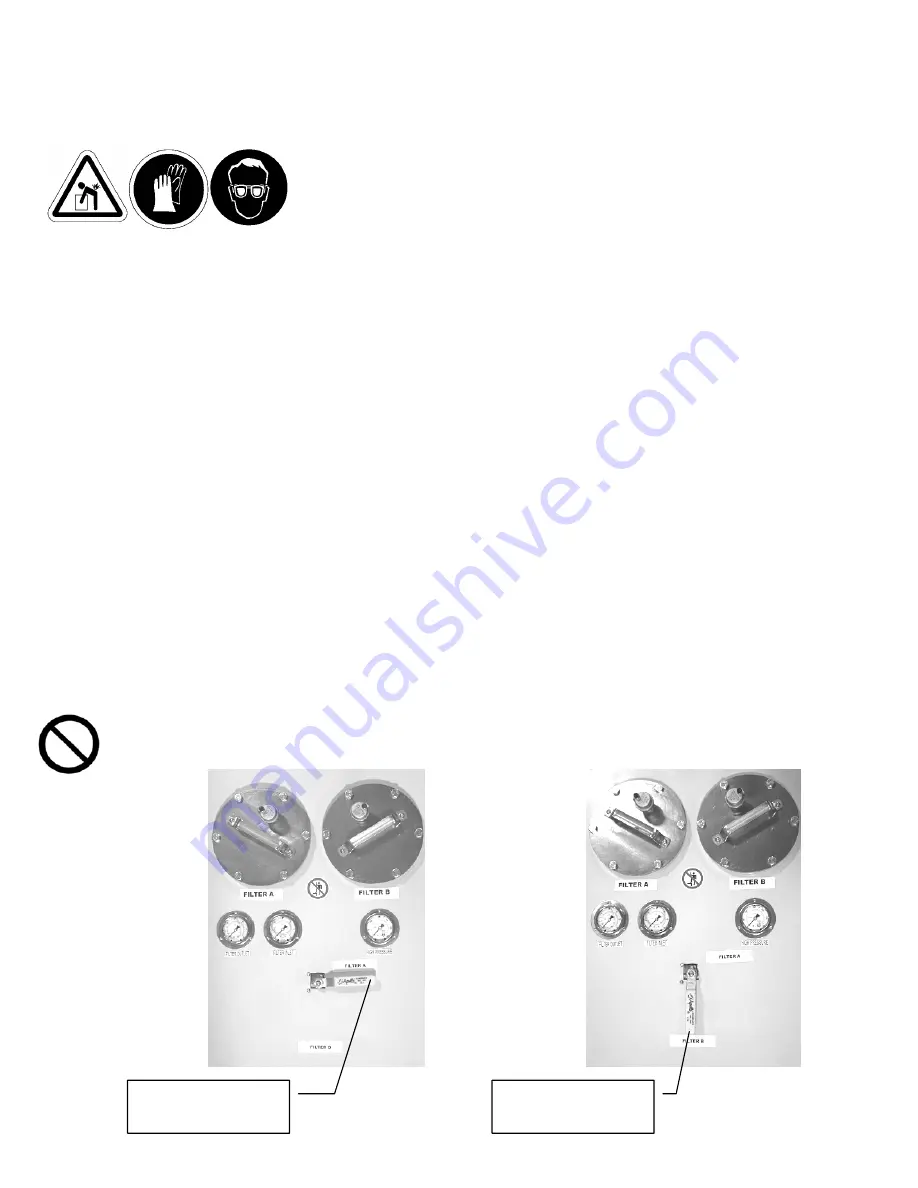

14.14.11. Turn the handle of the filter ball valve to the desired filter, “A” or “B”.

DO NOT REUSE DIRTY FILTER CARTRIDGES.

14.13–14.14

Handle Position

RUN FILTER “A”

Handle Position

RUN FILTER “B”