Page 11

Drive Belts & Power Transmission

The FM Series Flail Mowers utilize two drive belts (2 x BX41 / 16 X 1115), driven through a centrifugal clutch, with a

spring tensioned idler system to compensate for wear of the belts and pulleys.

The drive belts are designed as a ‘weak

-

link’ in the drivetrain, such that the belts will fail before damage is ca

used to

the engine if a foreign object is encountered or rotor entanglement occurs. Drive belts are a wearing part and as

such are not covered by the machine warranty.

NOTE: Always replace belts as a pair. Replace with ‘matched set’

belts which have a consistent belt length.

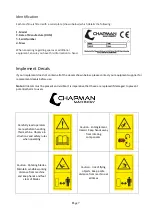

Belt Replacement

New Type Tensioner (09/14 - Present)

1.

With the height at the highest setting, this should allow the easiest access without removing the wheels.

Alternatively, remove the wheel on the engine side, once the machine is suitably supported with chocks or

similar.

2.

Remove the belt guard by loosening the 2 17mm bolts marked ‘B’, and fully removing the bolt marked ‘A’.

3.

Slacken the tensioner adjuster bolt using two 17mm spanners, shown as part ‘C’ above. The tensioner adjust

er

should be slackened to such a point as the spring can be removed by hand from the tensioner arm, as shown

by the right-hand image above.

4.

At this point the tensioner arm will be free to rotate, allowing full access

to the belts. The belts can then be r

emoved by ‘winding’ over the lower

pulley. Take care when removing / replacing belts not to lever the belt

or damage in any way, as this will greatly reduce belt life. The belts

should be able to be fitted by hand, without using any forcing tools.

5.

Replacement is a reversal of removal. Belts should be tensioned to 5mm

deflection at 15kgf. As a rough guide each belt should deflect

approximately 5mm under medium thumb pressure applied at the

midpoint of the belt between the two pulleys. Both belts should deflect to

the same degree.