Page 12

Maintenance

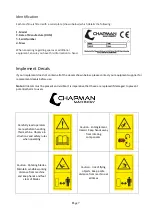

All maintenance, cleaning and repair operations must be performed with the machine suitably supported, the

engine switched off (and cool), and the ignition keys removed.

NOTE: For commercial use, log hours of operation in a maintenance booklet to ensure proper maintenance

intervals and continued service.

Maintenance Schedule

After first 1 hours of work

•

Check all nuts and bolt for tightness

–

retighten if required.

•

Check belt tension and taper lock tightness

–

adjust / tighten if required

(refer to belt section for details of adjustment).

Every 8 hours or daily

CHECK

•

Check all nuts and bolt for tightness

–

retighten if required.

•

Check belt condition and replace if necessary

•

Check wear and condition of flails

–

replacing missing, or damaged flails immediately.

•

Check condition of safety guards

–

repair or replace if not performing their function.

•

Check operation of emergency stop control

LUBRICATE

•

Lubricate rotor bearings

–

Apply grease to the two main rotor bearings. See below for locations of the

•

grease points.

•

Lubricate rear roller bearings - Apply grease to the two rear roller bearings. See below for locations of the

grease points.

•

Lubricate cross shaft bearings (Centre-mount only) - Apply grease to the two cross shaft bearings. See

below for locations of the grease points.

After every 100 hours (or annually, whichever occurs first), in addition to the above

CHECK

•

Check belt condition - replace if required

•

Check axle bearing condition - replace or lubricate as required

•

Check rear roller condition - replace if required

•

Check main rotor bearing condition - replace if required

•

Check condition of battery & connections

•

Check condition of fuel lines & replace if damaged or perished

•

Check condition of battery cables - replace if worn.

•

Check condition of flexible coupling (Centre mount models only)

•

Check clutch operation (disengage at idle, engage at approx. 30% throttle)

Tyre Pressures

FM range

- 22x11x8 0.50-0.82 bar (7-12 psi)