Page 14

Flail Condition & Replacement

Over time, the flails on your machine will wear, and performance will deteriorate. It is important that the flails are

kept in good condition to ensure a long service life of your machine. Flails should be replaced when either; 3mm

has worn off the end of the flail; the flail has become blunt or damaged; flails are missing.

When replacing flails the diametrically opposite flail should be replaced at the same time in order to maintain rotor

balance, When flails are fitted in pairs, (e.g. Y Grass Flails), both must be replaced at the same time. As flails are

fitted in a spiral pattern care must be taken to replace the correct diametrically opposite flails.

When replacing flails visually inspect the mounting bolts and bushes, if applicable. These are all wearing part and

normally should be replaced at the same time as the flails.

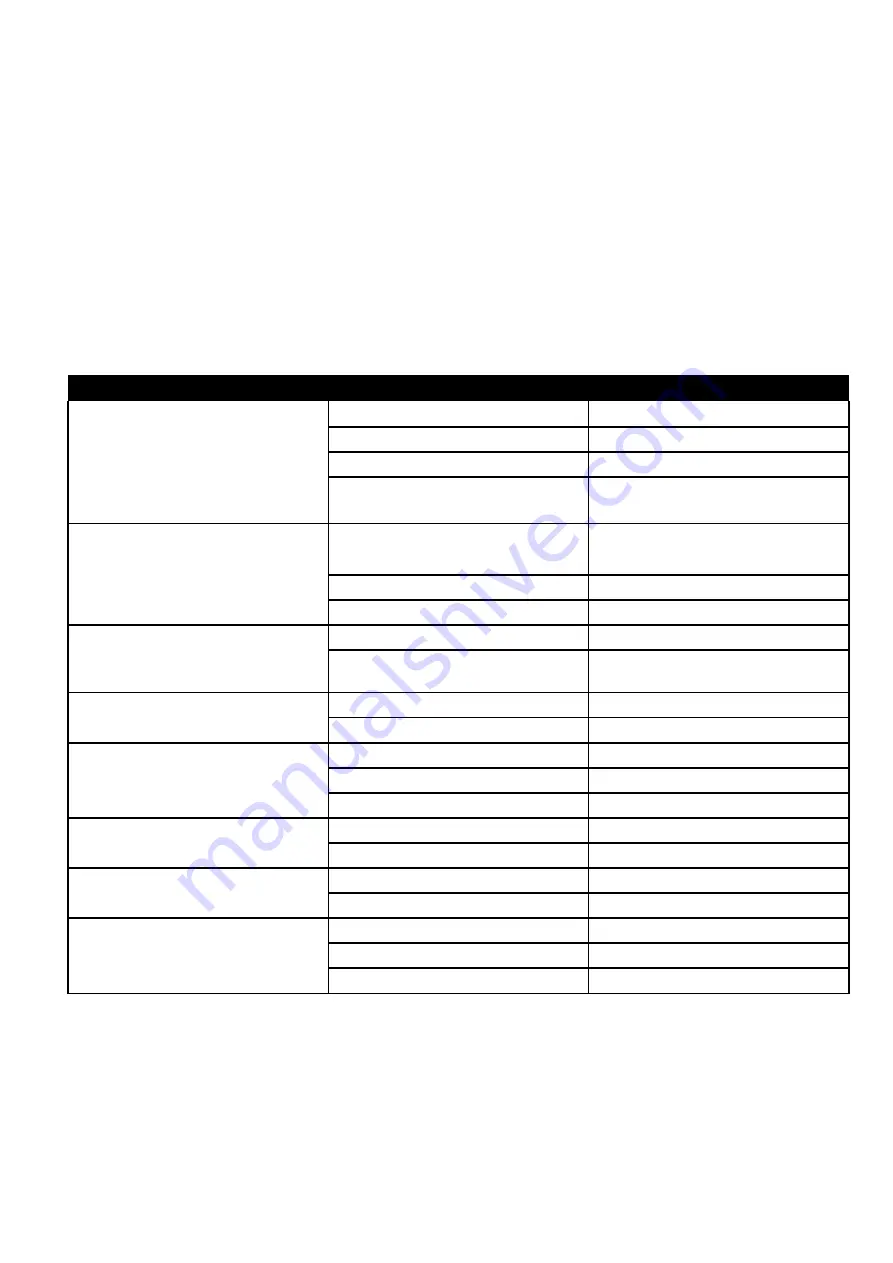

Troubleshooting

Problem

Possible Causes

Remedies

Irregular Cut

Worn, bent or broken flails

Inspect & replace & damaged flails

RPM too low

Always use maximum throttle

Machine not level to the ground

Check & adjust tyre pressures

Clogged material caused by exces- sive

forward speed

Reduce forward speed

Excessive Machine Noise

Unbalanced Rotor

Check flails & replace any damaged flails. If

vibration persists, see

“vibration”

below

Loose bolts

Check bolts & tighten as necessary

Damaged components

Repair or replace

Excessive Engine Noise

Worn muffler

repair or replace

Engine problems

Consult authorized dealer or

Chapman Machinery

Excessive Belt Noise

Belts slipping

Adjust belt tensioner

Belts worn

Replace belts

Vibration

Worn, bent or broken flails

Inspect and replace as necessary

Rotor out of balance

Balance or replace rotor

Worn rotor bearings

Replace rotor bearings

Excessive movement of drawbar

Worn drawbar pins

Replace drawbar pins

Loose drawbar hand screws

Tighten hand screws

Bearings tight or overheating

Bearings dirty or ungreased

Clean & grease bearings

Bearings worn to excess

Replace bearings

Belts Overheating

Belts slipping on pulleys

Tension belts

Flails contacting the ground

Raise cutting height

Working speed too high

Reduce forward speed

Machine Disposal

Disposal of this machine and any of its component parts must be performed in a responsible and inoffensive

manner respecting all current laws relating to this subject. Materials forming this machine that must undergo

differentiated division and disposal are:

Steel, Mineral Oil, Rubber & Plastic