13-11-614 Page 50

SECTION 6

AIR FILTER

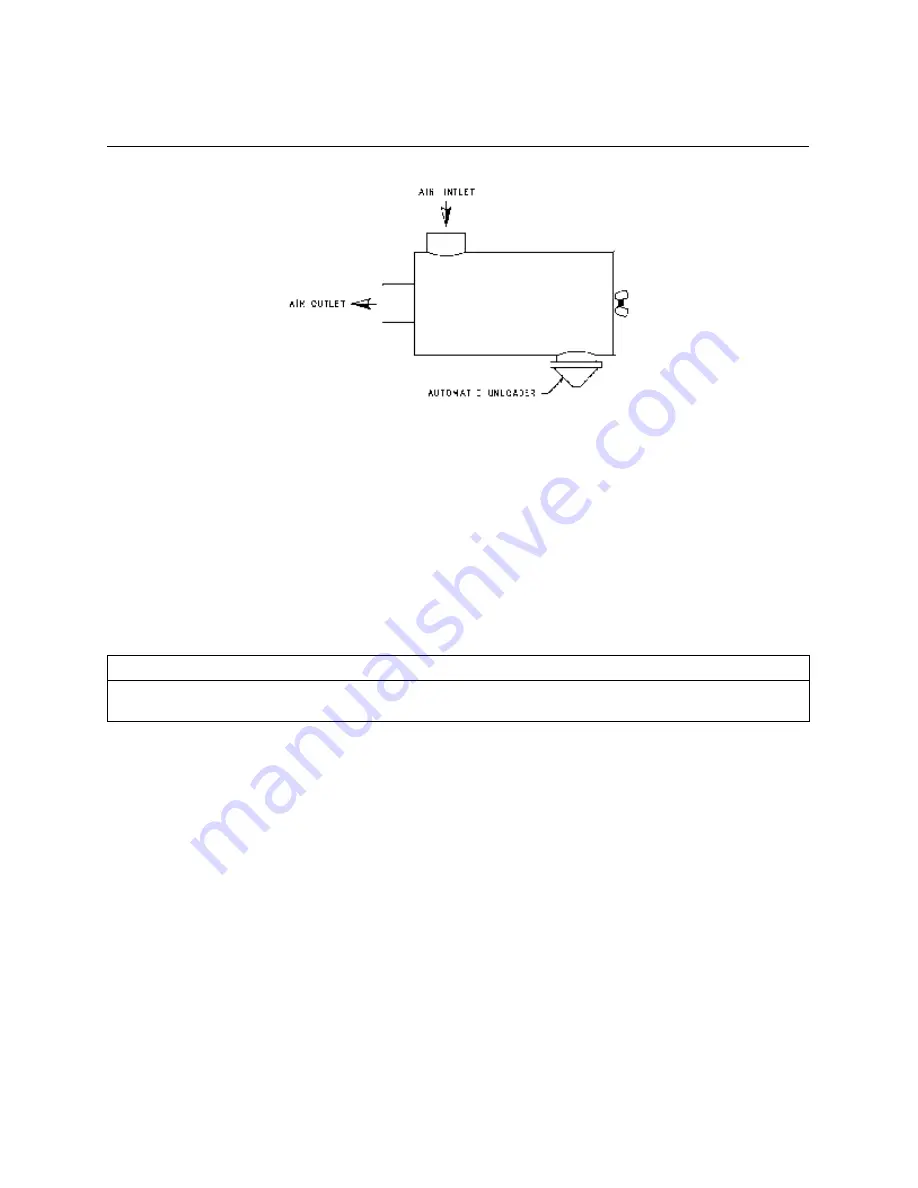

Figure 6-1 – HEAVY DUTY AIR FILTER (STANDARD)

HEAVY-DUTY AIR FILTER

(Figure 6-1) furnished as standard equipment on units with an enclosure is a

heavy-duty washable element dry type air filter. The air filter must receive proper maintenance if

maximum service is to be obtained from the unit. Establishing adequate and timely filter service is MOST

IMPORTANT. Improperly maintained air filter can cause a loss of compressor air delivery.

Filter Element

- Service the air filter element when the “CHANGE AIR FILTER” message appears on

the display accompanied by a yellow indicator in the status area of the keypad. Clean every 50 to 150

operating hours depending on dust conditions.

NOTICE

Use only genuine Champion air filter elements on Champion compressor units.

Genuine parts are available through your authorized Champion distributor.

To service:

1.

Remove the wing nut and pull out the filter element.

2.

Visually inspect the element. If cleaning is not necessary, reinstall the filter element. If the element

requires cleaning, go through Steps 3, 4 and 5.

3.

Wash the element by soaking about 15 minutes in warm water with a mild non-sudsing detergent.

Rinse the element thoroughly with clean water; a hose may be used if the water pressure does

not exceed 40 psig (2.8 bar).

4.

Inspect the element for ruptures or cracks in the pleated media; replace the element if any are

found. Inspect the gasket on the bottom (outlet end) of the element; replace the entire element if

the gasket is damaged. A spare element will keep down time to a minimum.

5.

Allow the element to air dry COMPLETELY. Do not expose the element to heat over 150

°

F (66

°

C). Install the element in the filter body and fasten securely with the wing nut.

Summary of Contents for ROTORCHAMP EWF99C-100

Page 7: ...13 11 614 Page 7 Figure 1 2 PACKAGE ILLUSTRATION AIR COOLED 309EWF797 A Ref Drawing ...

Page 8: ...13 11 614 Page 8 Figure 1 3 PACKAGE ILLUSTRATION WATER COOLED 310EWF797 A Ref Drawing ...

Page 9: ...13 11 614 Page 9 Figure 1 4 AIR COOLED SCHEMATIC 307EWF797 A Ref Drawing ...

Page 10: ...13 11 614 Page 10 Figure 1 5 WATER COOLED SCHEMATIC 308EWF797 A Ref Drawing ...

Page 29: ...13 11 614 Page 29 Figure 4 2 FLOW CHART FOR SETUP PROGRAMMING 300EWC1255 Ref Drawing ...

Page 43: ...13 11 614 Page 43 303EWF546 A Ref Drawing Page 2 of 2 ...

Page 45: ...13 11 614 Page 45 304EWF546 A Ref Drawing Page 2 of 2 ...

Page 47: ...13 11 614 Page 47 305EWF546 A Ref Drawing Page 2 of 2 ...