13-11-614 Page 62

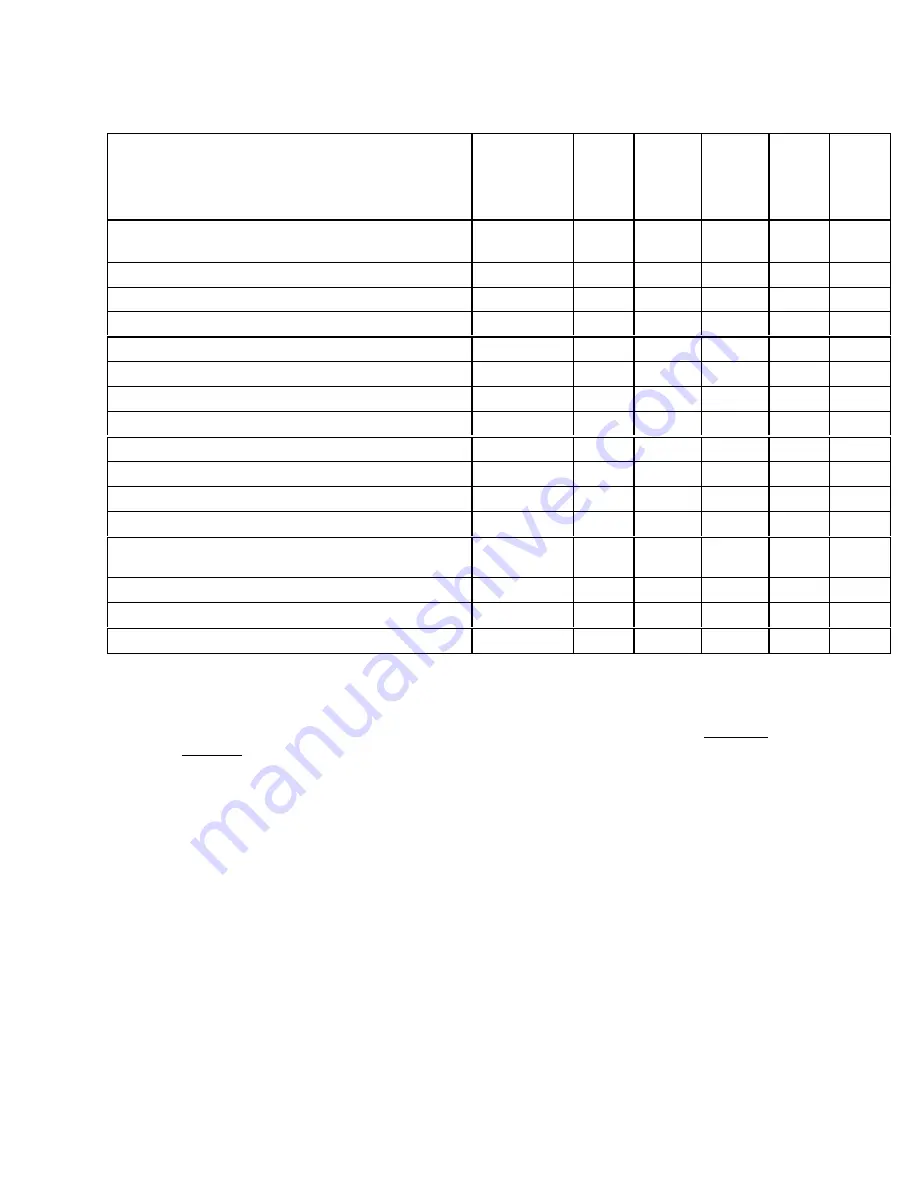

MAINTENANCE SCHEDULE (See Detail Notes)

Maintenance Action

As

indicated

by AUTO

SENTRY W

Every

8

Hours

Every

125

Hours

Every

500

Hours

Every

2000 *

Hours

Every

Year

Change Air Filter

•

Change Water Filter

•

Check for Proper Load/Unload

Check Discharge Pressure/Temp

•

Check Dirt Accumulation on Cooler

•

•

Check Reservoir Oil Level

•

Change Compressor Lubricant (RotorLub)

•

•

•

Check Relief Valve

•

Check Minimum Pressure Valve Seals

•

Change Oil Filter Element

•

•

Check Water Quality **

•

Check Water Flow (RO Filter Discharge)

•

Check Condensate Flow at Aftercooler Separator

Drain

•

Check Condensate Level in Control Air Filter Bowl

•

Check Setting of Buffer Air Pressure Regulator

•

Check Setting of Buffer Water Pressure Regulator

•

*

IF OIL IS ANALYZED at the end of a maintenance interval (2000 hr. max.), and is found in

good condition, it may be used for the next 2000 hour interval – GD provides free oil analysis

services. OTHERWISE, IF OIL IS NOT ANALYZED at the end of any interval, it must be

changed.

**

Depends on water quality – longer periods may be used when the quality of water meets or

exceeds our standards consistently.

Summary of Contents for ROTORCHAMP EWF99C-100

Page 7: ...13 11 614 Page 7 Figure 1 2 PACKAGE ILLUSTRATION AIR COOLED 309EWF797 A Ref Drawing ...

Page 8: ...13 11 614 Page 8 Figure 1 3 PACKAGE ILLUSTRATION WATER COOLED 310EWF797 A Ref Drawing ...

Page 9: ...13 11 614 Page 9 Figure 1 4 AIR COOLED SCHEMATIC 307EWF797 A Ref Drawing ...

Page 10: ...13 11 614 Page 10 Figure 1 5 WATER COOLED SCHEMATIC 308EWF797 A Ref Drawing ...

Page 29: ...13 11 614 Page 29 Figure 4 2 FLOW CHART FOR SETUP PROGRAMMING 300EWC1255 Ref Drawing ...

Page 43: ...13 11 614 Page 43 303EWF546 A Ref Drawing Page 2 of 2 ...

Page 45: ...13 11 614 Page 45 304EWF546 A Ref Drawing Page 2 of 2 ...

Page 47: ...13 11 614 Page 47 305EWF546 A Ref Drawing Page 2 of 2 ...