Installation

38

Rev. 10/17

Brave 30 ES - Brave 60 ES - Brave 90 ES

4.6 Adjusting the carbon

dioxide (CO

2

) supply

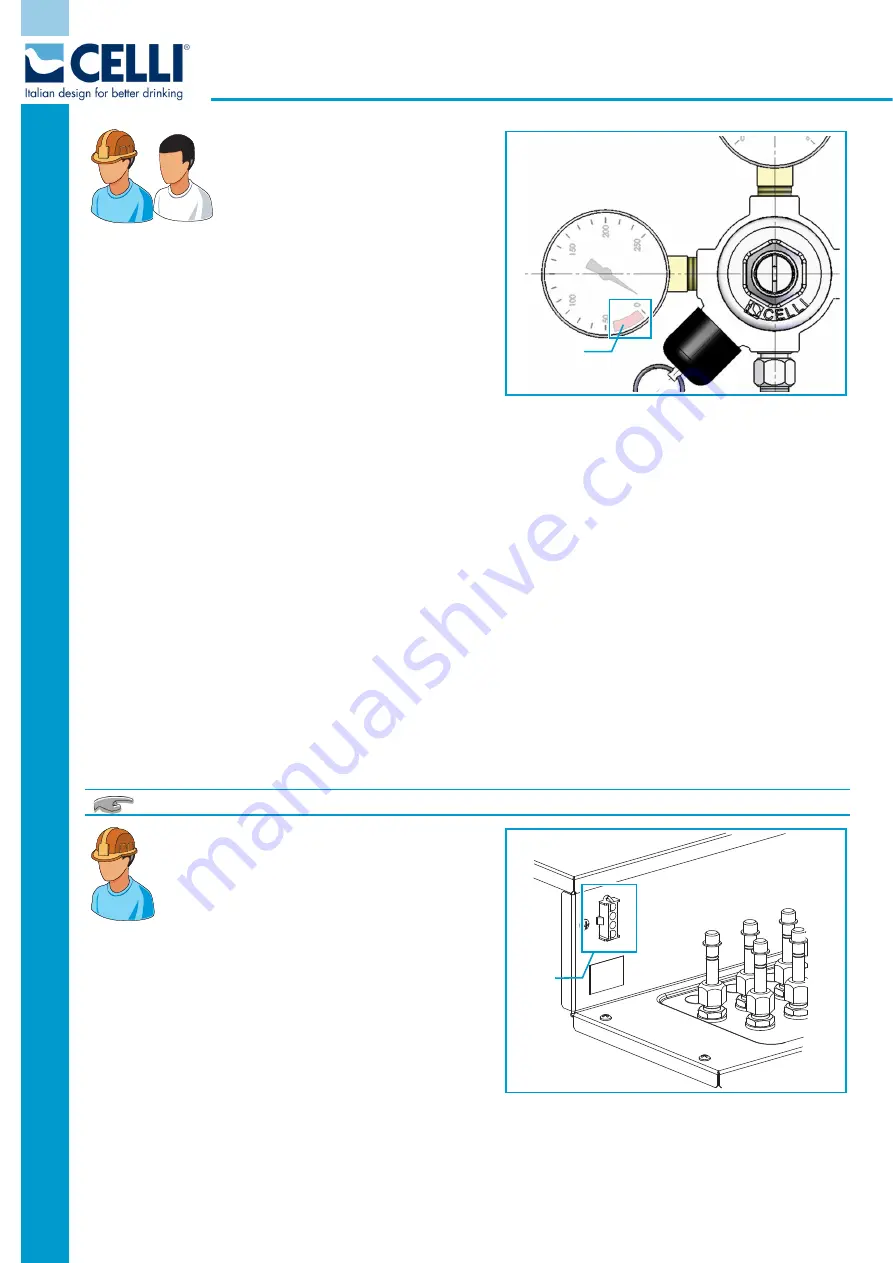

1 -

Slowly open the valve of the CO

2

cylinder until it is fully open. Check

the gas cylinder pressure is always

above the red segment (

A

- low level) of the pressure

reducer pressure gauge; otherwise, the cylinder will have

to be changed.

2 - CO

2

supply to the machine

: turn the adjuster

screw until the needle of the corresponding pressure

gauge reaches 5 bar (73 psi - 0,5 MPa). This value will

depend on the degree of carbonation required.

3 - CO

2

supply to the syrup lines:

•

Syrup in a bag-in-box (BIB):

adjust the supply pressure of the pneumatic pumps to 3 bar (42 psi -

0,3 MPa) - do not exceed 4.8 bar (70 psi - 0,48 MPa).

(Refer to the specifications of the type of pneumatic pump actually used).

•

Syrup in a steel keg:

adjust the pressure to 3 bar (42 psi - 0,3 MPa) for standard syrups, and 1 bar

(14,5 psi - 0,1 MPa) for diet syrups. (Refer to the specifications of the type of syrup actually used).

Connect the plug to a suitable power supply socket, checking that the characteristics of the electricity supply

system correspond to the appliance's technical data.

Make sure the I/0 switch is on

I

, and the pump buttons on the keypad are

ON

.

Check the fan unit and compressor are working. The compressor and fan unit will start with a 4-minute delay

to allow the pressure levels in the circuit to become stable.

After a few minutes, the surface of the condenser starts to heat up; check that this is happening.

If the fan unit and/or compressor are not working, call the after-sales service.

The machine is equipped with an external connector that can be used to obtain a 24V power supply.

Connector (B)

To use for connecting to a dispensing tower

(dispensing valves, any lighting, eventual

buzzer alarm).

The connector supplies 24VAC and 160VA.

For the connection between the machine and

the dispensing tower use cables with a cross-section of

1.5 mm

2

of the H05 VV-F variety.

Do not connect devices different from the dispensing

tower.

BR0181

A

BR0202

B