Operating instructions

22

6

Operating

instructions

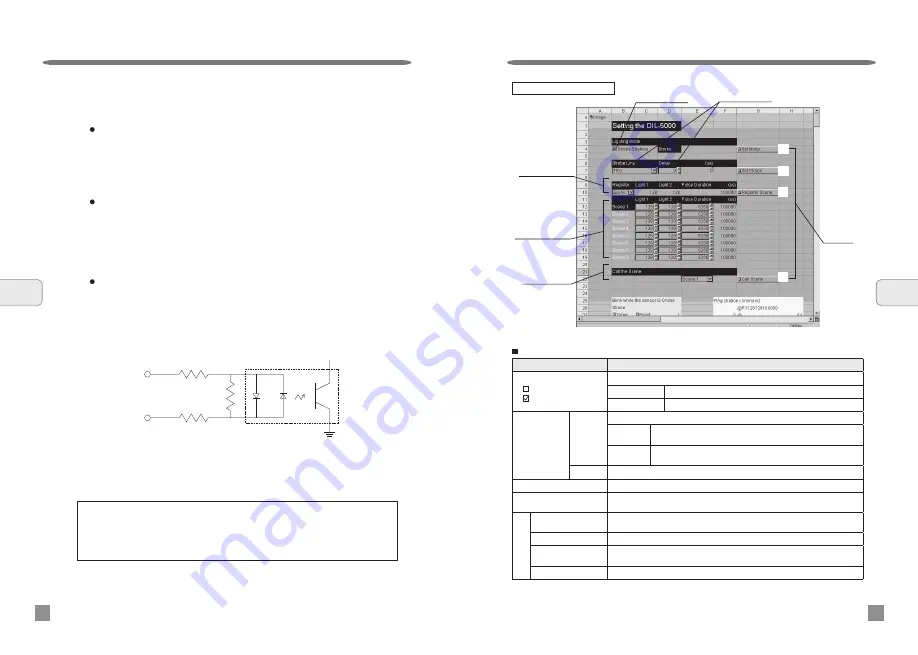

Mode selection

Strobe setting

Display of

scene selected

Display of list of

scenes

Function

buttons

Default values: Light control; 128, Light pulse width; 100000, Emission timing; 0, Delay time; 0000

(1)

List of setting job functions

Function

Description

Mode selection

: Always

: Strobe Enabled

Used to select light control method.

Always

Used for stationary light.

Strobe Enabled

Used for strobe light (with no overdrive).

Strobe setting

Note: Enabled

only when strobe

light mode is

selected.

Pulse

timing

Used to select a trigger signal.

TRG

Use a trigger output from external control equipment such as a PLC.

(Trigger port No.0)

HSOUT1

Use high-speed output from the In-Sight5000 as a trigger.

(Trigger port No.1)

Delay time

Used to set to a total of 64 steps in 16-μs units in the range of 0 to 1,008μs.

Display of scene selected

Select the current scene and display it.

Display of list of scenes

Indicates datas for every sequence.

Make settings of light control data and pulse duration by scene.

Fu

nc

tio

n b

utt

on

s

(1)Set Mode button

Used to transmit an instruction to shift the system to mode selected to the DIL

interface unit.

(2)Set Strobe button

Used to transmit the set values of trigger port and delay time to the DIL interface unit.

(3)Register Scene button Used to transmit every scene data to the DIL interface unit and save it in the internal

memory.

(4)Call the Scene button Used to call scene data saved in the internal memory of the DIL interface unit.

For detail of strobe setting, please refer to information on page 14.

For detail of settings of light control and light pulse width, please refer to information on page 15.

Call the Scene

2.

2k

4.7k

TRG -

TRG +

4.7k

Operating instructions

21

For the use of the In-Sight 5000 series from Cognex, thoroughly read its

User manual.

For the use of the extension I/O module 1450 or 1460 from Cognex,

thoroughly read their User manual.

(2)

(3)

(4)

In order to use external control equipment output, such as a pull-down

type PLC, as a trigger:

Connect “TRG+” to +24V and “TRG-” to output. If the output turns

ON, “TRG-” will be pulled down to 0V, and the input photocoupler will

turn ON.

*It uses external control equipment, such as an extension I/O module or a PLC,

directly as a trigger.

2) When the Trigger Port “No. 0” is used

In order to use external control equipment output, such as a pull-up type

PLC, as the trigger:

Connect “TRG+” to output and “TRG-” to 0V. If the output turns ON,

“TRG+” will be pulled up to 24V, and the input photocoupler will turn

ON.

If the extension I/O module 1450 or 1460 from Cognex is used, connect

the “PIN 2” of the terminal block of the extension I/O module to “TRG+” and

“PIN 3” to “TRG-”.

Trigger input circuit diagram

Note: Please refer to page 15 for response time after receiving trigger.

Setting Job window

6

Operating

instructions