29

Sensor and Controller Tests

SENSOR ALARM TEST

The sensor alarm test checks a sensor’s ability to signal an

alarm state. This test requires the use of a field-provided SD-

MAG test magnet.

SENSOR ALARM TEST PROCEDURE

1. Hold the test magnet where indicated on the side of the

sensor housing for seven seconds.

2. Verify that the sensor’s Alarm LED turns on.

3. Reset the sensor by holding the test magnet against the

sensor housing for two seconds.

4. Verify that the sensor’s Alarm LED turns off.

CONTROLLER ALARM TEST

The controller alarm test checks the controller’s ability to initi-

ate and indicate an alarm state.

CONTROLLER ALARM TEST PROCEDURE

1. Press the controller’s test/reset switch for seven seconds.

2. Verify that the controller’s Alarm LED turns on.

3. Reset the sensor by pressing the test/reset switch for

two seconds.

4. Verify that the controller’s Alarm LED turns off.

DIRTY CONTROLLER TEST

The dirty controller test checks the controller’s ability to initi-

ate a dirty sensor test and indicate its results.

DIRTY CONTROLLER TEST PROCEDURE

• Press the controller’s test/reset switch for two seconds.

• Verify that the controller’s Trouble LED flashes.

DIRTY SENSOR TEST

The dirty sensor test provides an indication of the sensor’s abil-

ity to compensate for gradual environmental changes. A sensor

that can no longer compensate for environmental changes is

considered 100% dirty and requires cleaning or replacing. You

must use a field provided SD-MAG test magnet to initiate a

sensor dirty test. The sensor’s Dirty LED indicates the results

of the dirty test as shown in Table 6.

DIRTY SENSOR TEST PROCEDURE

1. Hold the test magnet where indicated on the side of the

sensor housing for two seconds.

2. Verify that the sensor’s Dirty LED flashes.

CHANGING THE DIRTY SENSOR TEST

By default, the dirty sensor test results are indicated by:

• The sensor’s Dirty LED flashing.

• The controller’s Trouble LED flashing.

• The controller’s supervision relay contacts toggle.

The operation of a sensor’s dirty test can be changed so that the

controller’s supervision relay is not used to indicate test results.

When two detectors are connected to a controller, sensor dirty

test operation on both sensors must be configured to operate in

the same manner.

TO CONFIGURE THE DIRTY SENSOR TEST OPERATION

1. Hold the test magnet where indicated on the side of the

sensor housing for approximately 60 seconds until the sen-

sor’s Alarm LED turns on and its Dirty LED flashes twice.

2. Reset the sensor by removing the test magnet and then

holding it against the sensor housing again for approxi-

mately 2 seconds until the sensor’s Alarm LED turns off.

REMOTE STATION TEST

The remote station alarm test checks a test/reset station’s abili-

ty to initiate and indicate an alarm state.

SD-TRK4 REMOTE ALARM TEST PROCEDURE

1. Turn the key switch to the RESET/TEST position for

seven seconds.

2. Verify that the test/reset station’s Alarm LED turns on.

3. Reset the sensor by turning the key switch to the RESET/

TEST position for two seconds.

4. Verify that the test/reset station’s Alarm LED turns off.

REMOTE TEST/RESET STATION DIRTY SENSOR TEST

The test/reset station dirty sensor test checks the test/reset sta-

tion’s ability to initiate a sensor dirty test and indicate the re-

sults. It must be wired to the controller as shown in Fig. 36 and

configured to operate the controller’s supervision relay. For

more information, see “Changing the Dirty Sensor Test.”

IMPORTANT: Failure to follow this NOTICE may result in

an unnecessary evacuation of the facility.

This test places the duct detector into the alarm state.

Unless part of the test, disconnect all auxiliary equipment

from the controller before performing the test. If the duct

detector is connected to a fire alarm system, notify the

proper authorities before performing the test.

IMPORTANT: Failure to follow this NOTICE may result in

an unnecessary evacuation of the facility.

This test places the duct detector into the alarm state.

Unless part of the test, disconnect all auxiliary equipment

from the controller before performing the test. If the duct

detector is connected to a fire alarm system, notify the

proper authorities before performing the test.

IMPORTANT: Failure to follow this NOTICE may result in

an unnecessary evacuation of the facility.

Pressing the controller’s test/reset switch for longer than

seven seconds will put the duct detector into the alarm state

and activate all automatic alarm responses.

IMPORTANT: Failure to follow this NOTICE may result in

an unnecessary evacuation of the facility.

Holding the test magnet against the sensor housing for

more than seven seconds will put the duct detector into the

alarm state and activate all automatic alarm responses.

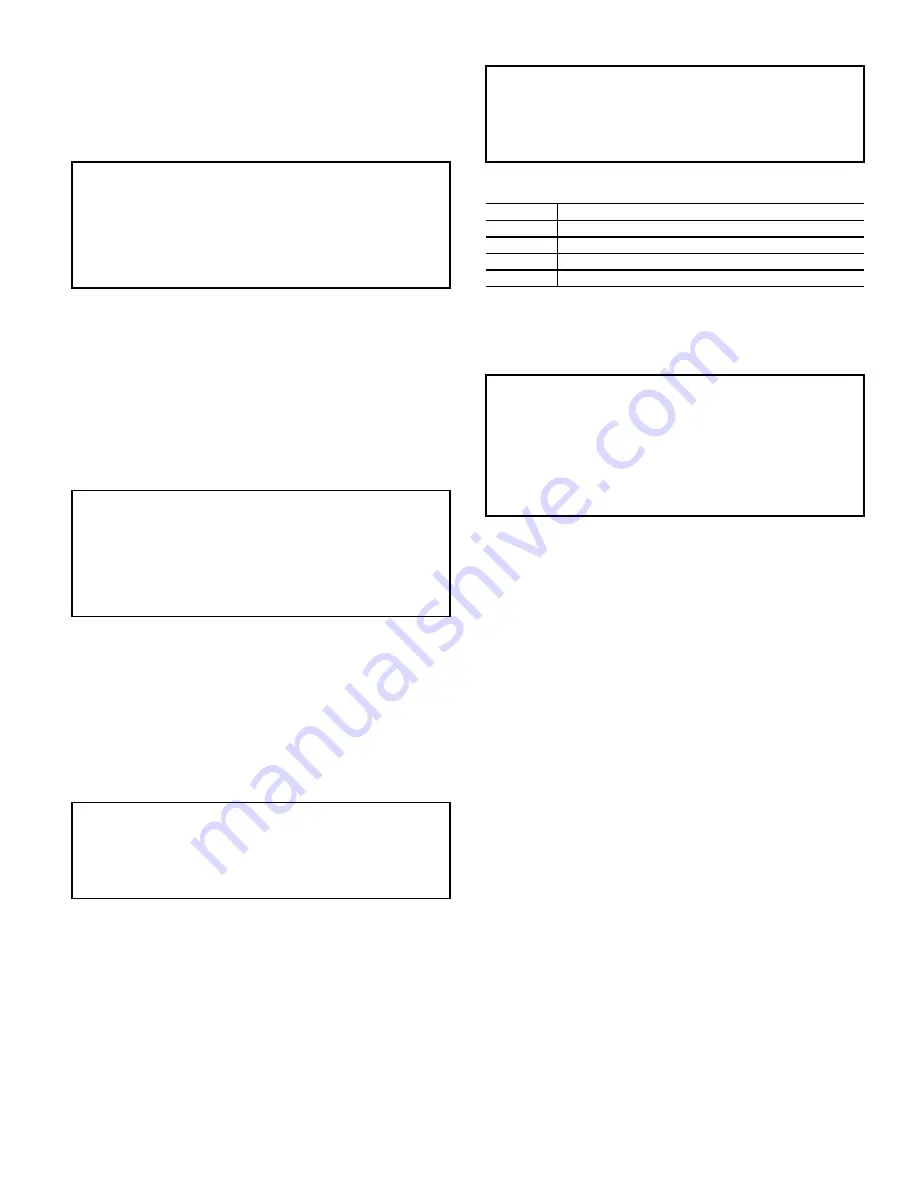

Table 6 — Dirty LED Test

FLASHES

DESCRIPTION

1

0-25% dirty. (Typical of a newly installed detector)

2

25-50% dirty

3

51-75% dirty

4

76-99% dirty

IMPORTANT: Failure to follow this NOTICE may result in

an unnecessary evacuation of the facility.

Changing the dirty sensor test operation will put the detec-

tor into the alarm state and activate all automatic alarm

responses. Before changing dirty sensor test operation, dis-

connect all auxiliary equipment from the controller and

notify the proper authorities if connected to a fire alarm

system.

Summary of Contents for WeatherMaster Puron 48HC D17

Page 18: ...18 COOLING CHARGING CHARTS Fig 22 Cooling Charging Chart 15 Ton ...

Page 19: ...19 Fig 23 Cooling Charging Chart 17 5 Ton ...

Page 20: ...20 Fig 24 Cooling Charging Chart 20 Ton ...

Page 21: ...21 Fig 25 Cooling Charging Chart 25 Ton ...

Page 37: ...37 Fig 48 Unit Control Box IGC Location IGC Board IGC Board Side view Front view ...

Page 40: ...40 Fig 51 Typical IGC Wiring Diagram ...

Page 46: ...46 Fig 57 RTU Open Overlay for Economizer Wiring ...

Page 47: ...47 Fig 58 VFD Overlay for W2770 Controller Wiring ...

Page 84: ...84 Fig B 48HC D17 D28 Control Diagram 208 230 3 60 460 575 3 60 ...

Page 85: ...85 Fig C 48HC D17 D28 Power Diagram 208 230 3 60 ...

Page 86: ...86 Fig D 48HC D17 D28 Power Diagram 460 3 60 ...

Page 87: ...87 Fig E 48HC D17 D28 Power Diagram 575 3 60 ...

Page 88: ...88 Fig F 48HC D17 D28 Control Diagram with Humidi MiZer System ...

Page 89: ...89 Fig G 48HC D17 D28 Power Diagram 208 230 3 60 with Humidi MiZer System ...

Page 90: ...90 Fig H 48HC D17 D28 Power Diagram 460 3 60 with Humidi MiZer System ...

Page 91: ...91 Fig I 48HC D17 D28 Power Diagram 575 3 60 with Humidi MiZer System ...

Page 92: ...92 Fig J PremierLink System Control Wiring Diagram 50HE500891 F ...

Page 93: ...93 Fig K PremierLink System Control Wiring Diagram with Humidi MiZer System ...

Page 94: ...94 Fig L RTU OPEN Wiring Diagram ...

Page 95: ...95 Fig M RTU OPEN Wiring Diagram with Humidi MiZer System ...

Page 97: ......