1-15

The operator may adjust the opening to increase or

decrease the air flow volume to meet the required air

flow.

b. Air Sampling for Carbon Dioxide (CO

2

) Level

Loosen wing nuts and move cover until the arrow on

the cover is aligned with the “atmosphere sampling port”

label. Tighten wing nuts and attach a 3/8 tube to the

sampling tube.

If the internal atmosphere content has reached an

unacceptable level, the operator may adjust the cover

opening to meet the required air flow volume to ventilate

the container.

1.9

REMOTE MONITORING (OPTIONAL)

NOTE

Models with an in-range light, the light will be

illuminated if the container control air

temperature is within the tolerance selected.

Refer to section 1.12.5.

When the remote monitor is connected to the

remote monitoring receptacle, the following remote

circuits are energized.

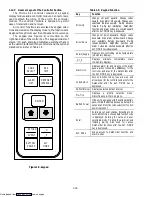

Circuit

Function

Sockets B to A

Energizes remote cool light

Sockets C to A

Energizes remote defrost light

Sockets D to A

Energizes remote in-range light

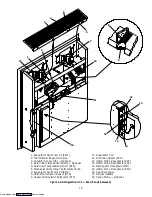

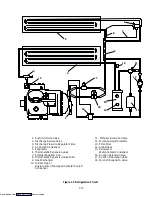

1.10 SUCTION SOLENOID VALVE

The suction solenoid valve, shown in Figure 1-3 is

controlled by the controller relay TS.

a. Operation

If set point is below ---10

_

C (+14

_

F) or ---5

_

C

(+23

_

F) optionally, the controller relay (TS) closes to

energize the suction solenoid valve (SSV). Once opened,

the refrigerant flow rate and unit cooling capacity is

increased.

If set point is above ---10

_

C (+14

_

F) or ---5

_

C

(+23

_

F) optionally, and the suction solenoid valve (SSV)

override is not activated, suction solenoid valve opens

during temperature pulldown period unless current

limiting or suction solenoid override restricts its use.

b. Suction Solenoid Override

This function restricts the opening of the suction

solenoid valve (SSV) under certain high ambient and/or

box temperature conditions. If the primary return sensor

(RTS) fails (AL56), the suction solenoid valve will not

open unless the ambient temperature is less than 10

_

C

(50

_

F). If the ambient sensor fails (AL57), the suction

solenoid valve will not be allowed to open until the return

air temperature is less than 1.67

_

C (35

_

F). If both the

ambient and return air (RTS) sensors fail, the suction

solenoid valve will not be allowed to open until at least

one of the sensors is repaired.

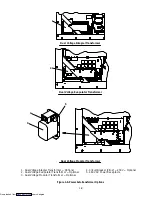

1.11 WATER-COOLED CONDENSER

(OPTIONAL)

The water-cooled condenser is used when cooling

water is available and heating the surrounding air is

objectionable, such as in a ship’s hold.

The water-cooled condenser is a shell and coil

condenser with water circulating through the

cupro-nickel coil. The refrigerant vapor is admitted to

the shell side and is condensed on the outer surface of the

coil.

To shift to water-cooled condenser operation, do the following:

a. Connect water supply line to inlet side of condenser

and discharge line to outlet side of condenser.

b. Maintain a flow rate of 11 to 26 liters per minute = 3

to 7 gallons per minute. The water pressure switch will

open to de-energize the condenser fan relay. The con-

denser fan motor will stop and will remain stopped until

the water pressure switch closes.

The refrigeration unit operating with the

water-cooled condenser will perform as outlined in

section 2.4 except that the condenser fan motor is

stopped in all modes.

To shift to air-cooled condenser operation, do the

following:

Disconnect the water supply and the discharge line to

the water-cooled condenser. The refrigeration unit will

shift to air-cooled condenser operation when the water

pressure switch closes. (Refer to section 1.3.)

Downloaded from