4-19

3. Remove enclosing tube collar (item 4,

Figure 4-25) using installation/removal tool supplied

with repair kit (item 3).

4. Check plunger for restriction due to:

(a)

Corroded or worn parts; (b) Foreign material lodged in

valve; (c) Bent or dented enclosing tube.

5. Remove top plate, diaphragm spring, diaphragm

and body gaskets.

6. Install new parts, assemble in reverse order of

disassembly.

7. Torque the 4 capscrews to 40 inch pounds.

8. Do not overtighten enclosing tube assembly.

Torque to a value of 1.15 mkg (100 inch pounds).

9. Remove supplied installation/removal tool.

Install coil, and snap cap.

10. Dehydrate and evacuate the system. (Refer to

section 4.5) Charge unit with refrigerant per section

4.6.1.

11. Plug in the connector. Start unit and check

operation.

10

11

12

13

14

15

1

2

5

6

7

4

8

9

16

3

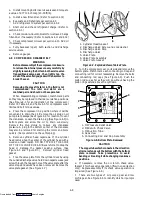

1. Snap Cap

2. Coil

3. Installation/Removal Tool

4. Enclosing Tube Collar

5. O-Ring

6. Enclosing Tube

7. Spring

8. Plunger

9. Gasket

10. Top Plate

11. Capscrews

12. Spring

13. Gasket

14. Diaphragm

15. O-Ring

16. Body

Figure 4-25. Suction Solenoid Valve --- Alco

4.25 SUCTION MODULATION VALVE (SMV)

NOTE

When repairing suction modulation valve with

the enclosing tube kit (CTD P/N 14-50021-01) be

sure not to remove items 7, 8 & 10. (See

Figure 4-26) Proper alignment of these items is

achieved only at the factory.

1

2

3

4

5

6

7

8

9

10

11

1. Coil Nut

2. Coil Nut O-ring

3. Coil Housing

4. Solenoid Coil Sleeve

5. Solenoid Coil

6. Enclosing Tube Assy.

7. Piston

8. Top Return Spring

9. Valve Body

10. Bottom Return Spring

11. Filter

Figure 4-26. Suction Modulation Valve

a. Coil Checkout Procedure

WARNING

Make sure power to the unit is OFF and power

plug disconnected before replacing the coil.

1. Disconnect the modulation valve coil wires by

unplugging the connector (Refer to section 5).

2. Using a reliable digital ohmmeter, test each

lead’s resistance to ground. If the resistance indicates a

ground short is present, inspect the length of wiring for

damaged or exposed wires. Replace where necessary.

3. Setting the digital ohmmeter for low range check

coil’s resistance. If coil’s resistance is below 5 ohms it is

recommended to be replaced. New coils have an

approximate resistance of 7.6 ohms at 25

_

C (77

_

F). The

chart below gives the resistance of a new coil at various

ambient temperatures.

Ambient Temperature

Cold Coil

10

_

F

6.45 ohms

40

_

F

6.90 ohms

70

_

F

7.40 ohms

100

_

F

7.90 ohms

Downloaded from