4-17

the refrigeration unit from the highly corrosive sea

atmosphere or if the protective paint system is scratched

or damaged, clean area to bare metal using a wire brush,

emery

paper or equivalent

cleaning method.

Immediately following cleaning, spray or brush on zinc

rich primer. After the primer has dried, spray or brush on

finish coat of paint to match original unit color.

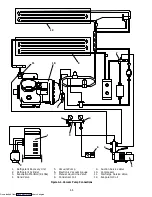

4.22 POWER AUTOTRANSFORMER (OPTIONAL)

The transformer is either the whole-unit transformer

(item 1 or item 3, Figure 1-6) or the evaporator

transformer (item 2, Figure 1-6). Also, refer to Table 1-1

to determine which transformer is listed for the unit.

For the modular transformer (item 3, Figure 1-6):

If the unit does not start, check the following:

a. Make sure the 460 vac (yellow) power cable is

plugged into the receptacle (item 5, Figure 1-6) and

locked in place.

b. Make sure that circuit breakers CB-1 and CB-2 are

in the “ON” position. If the circuit breakers do not hold

in, check voltage supply.

c. There is no internal protector for this particular

transformer design, therfore, no checking of the internal

protector is required.

For transformer (item 1, Figure 1-6) or the evaporator

transformer (item 2, Figure 1-6):

If the unit does not start when connected to a 190/230

vac power supply, check the following:

a. Make sure circuit breaker (CB-2) is in the ON

position. If CB-2 does not hold in, check voltage supply.

b. Check to see if the transformer internal protector

(IP-AUTO-TRANS) is closed. Allow a reasonable length

of time for transformer to cool down. The transformer

includes two (2) internal protectors. Only one is wired

into the system as the second protector is a spare.

c.

To Check for Continuity Across the Internal Protector

(IP-AUTO-TRANS):

1. Turn power OFF and disconnect power source.

2. Disconnect white wires

1 and 2

from the KA and

KB connector on the Controller.

3. Check for continuity across the internal

protector (IP). If (IP) is open and will not reset, connect

wires

3 and 4

(18 gauge) to the KA and KB connector.

Check to see if unit will start.

d. If the internal protector and circuit breakers (CB-1

and CB-2) are good, check the transformer. Use a

voltmeter and with the primary supply circuit ON check

the primary (input) voltage (230 vac). Next, check the

secondary (output) voltage (460 vac) at the voltage

selector switch. The transformer is defective if voltage is

not available.

4.23 SENSOR CHECKOUT PROCEDURE

(AMBS, DTS, RRS, RTS, SRS & STS)

An accurate ohmmeter must be used to check the

resistance values shown in Table 4-1.

Due to the variations and inaccuracies in

ohmmeters, thermometers or other test equipment, a

reading within 2% of the chart value would indicate a

good sensor. If a sensor is defective, the resistance

reading will usually be much higher or lower than the

resistance values given in Table 4-1.

4.23.1 Checking Sensor (RRS, RTS, SRS or STS)

a. Place the sensor (sensing bulb) in 0

_

C (32

_

F)

ice-water bath. Ice-water bath is prepared by filling an

insulated container (of sufficient size to completely

immerse bulb) with ice cubes or chipped ice, then filling

voids between ice with water, and agitating until mixture

reaches 0

_

C (32

_

F) as shown by a laboratory

thermometer.

b. Start unit and check air temperature/data readout on

the control panel. You should have a reading of 0

_

C

(32

_

F); if not, continue on to the following step.

c. Turn unit OFF and disconnect power supply.

d. Refer to section 4.28 for removal of the Controller or

DataCORDER module.

RTS or STS:

In the box there is a plug connector marked (EC) that

is connected to the Controller module, find the wires

marked RTS or STS, depending on which sensor needs

replaced. Follow that wire to the connector and using the

pins of the plug, measure the ohms resistance. Readings

are shown in Table 4-1.

RRS or SRS:

In the box there is a plug connector marked (ED)

that is connected to the optional DataCORDER module,

find the wires marked RRS or SRS, depending on which

sensor needs replaced. Follow that wire to the connector

and using the pins of the plug, measure the ohms

resistance. Readings are shown in Table 4-1.

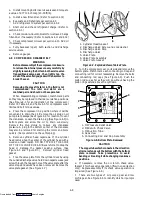

4.23.2 Replacing Sensor (RRS, RTS, SRS or STS)

a. Turn unit power OFF and disconnect power supply.

b. Cut cable 15.24 cm (6 inches) from shoulder of

defective sensor and discard.

c. Cut one wire of existing cable 25.4 mm (1.0 inch)

shorter than the other wire.

d. Cut one replacement sensor wire (opposite color)

back 25.4 mm (1.0 inch). (See Figure 4-21.)

Sensor

Shoulder

25.4 mm (1.0 inch)

6.35 mm (1/4 inch)

Figure 4-21. Sensor (RRS, RTS, SRS or STS)

e. Strip back insulation on all wiring 6.35mm (1/4 inch).

f. Slide a large piece of heat shrink tubing over the

cable and the two small pieces of heat shrink tubing over

the wires before adding crimp fittings as shown in

Figure 4-22.

Downloaded from