2-1

SECTION 2

OPERATION

2.1 PRE-TRIP INSPECTION (Before Starting)

WARNING

Beware of unannounced starting of the evaporator

and condenser fans.

a. If container is empty, check inside for the following:

1. Check channels or “T” bars on floor for

cleanliness. Channels must be free of debris for proper air

circulation.

2. Check container panels, insulation and door seals

for damage. Effect permanent or temporary repairs.

3. Visually check evaporator fan motor mounting

bolts for proper securement.

4. Check for dirt or grease on evaporator fan or fan

deck and clean if necessary.

5. Check evaporator coil for cleanliness or

obstructions. Wash with fresh water. (Refer to section 4.14)

6. Check defrost drain pans and drain lines for

obstructions and clear if necessary. Wash with fresh water.

7. Check panels on refrigeration unit for loose bolts

and condition of panels. Make sure T.I.R. devices are in

place on access panels.

b. Check condenser coil for cleanliness. Wash with fresh

water. (Refer to section 4.17)

c. Check position of fresh air makeup vent cover.

Operator must determine if fresh air makeup vent cover is

to be opened or closed.

d. Open Partlow recording thermometer (if so equipped)

door and do the following:

1. Manually wind clock on recording thermometer

(key is located in a clip.) KEY MUST STAY WITH THE

THERMOMETER

2. Lift stylus (pen) by pulling the marking tip outward

until the stylus arm snaps into it’s retracted position.

3. Install new chart on recording thermometer

making sure chart is under the four corner tabs. Lower the

stylus until stylus has made contact with the chart. Then

close and secure door.

e. Open Saginomiya recording thermometer (if so

equipped) door and do the following:

1. Check Chart drive battery condition. (Refer to

section 4.20)

2. Lift stylus (pen) by pushing in the stylus lifter and

rotating the lifter clockwise (raising stylus at same time)

until lifter locks in position.

3. Install new chart on recording thermometer

making sure chart is under the four corner tabs. Release

stylus lifter by pushing down and rotating lifter

counterclockwise until stylus lifter locks in position and

stylus has made contact with chart. Then close door.

f.

Open control box door. Check for loose electrical

connections or hardware.

g. Check color of moisture-liquid indicator.

h. Check oil level in compressor sight glass.

i.

Start refrigeration unit. (Refer to section 2.3.)

2.2 STARTING AND STOPPING INSTRUCTIONS

CAUTION

Make sure that the unit circuit breaker(s) (CB-1

& CB-2) and the start-stop switch (ST) are in the

OFF position before connecting to any electrical

power source.

a. Starting the Unit

1. Refer to Pre-Trip Inspection, section 2.1.

2. Check power source for proper voltage. Connect

unit power plug and turn main power ON.

3. Turn refrigeration unit circuit breaker(s), and the

start-stop switch ON (position “1”).

4.

Units equipped with a DataCORDER:

Trip start is initiated by depressing the ALT. MODE

key and selecting Code dc30, then depressing the

ENTER

key for 5 (five) seconds.

5. Refer to section 2.3 after unit is running.

b. Stopping the Unit

Turn the start-stop switch to position “0” (OFF

position).

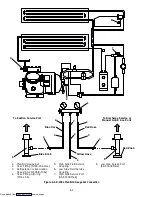

2.3 AFTER STARTING INSPECTION

a. Check rotation of condenser and evaporator fans.

b. Check compressor oil level. (Refer to section 4.10)

c. Run unit at least 5 minutes to stabilize. Start controller

Pre-Trip diagnostics. (Refer to section 1.13)

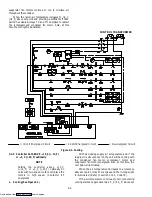

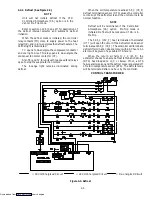

2.4 UNIT OPERATION

2.4.1 Crankcase Heater

Whenever the crankcase heater is installed,

it will be operational whenever the

compressor is off and their is power to the

unit. The heater is connected to a set of

normally closed auxillary contacts on the

compressor contactor.

2.4.2 Cooling --- Controller Set BELOW ---10

_

C (+14

_

F)

or ---5

_

C (+23

_

F) optionally

NOTES

1. The suction solenoid valve (SSV) will be open

to increase the refrigerant flow rate and

cooling capacity unless SSV override is

activated.

2. In the frozen range the suction modulation

valve is 100% open.

3. Setting the controller below ---10

_

C (+14

_

F)

or ---5

_

C (+23

_

F) optionally on units with

two-speed motors will place the motors in low

speed (contactor ES energized).

When the return air temperature decreases to 0.2

_

C

(0.4

_

F) below set point, relays TC and TN de-energizes.

This results in de-energizing the compressor and condenser

fan motor. Also, the cool light is de-energized. The

Downloaded from