ENG

“EVD Evolution TWIN” +0300006EN - rel. 2.6 - 31.01.2019

22

Note that control is calculated as the sum of three separate contributions:

proportional, integral and derivative.

•

the proportional action opens or closes the valve proportionally to the

variation in the superheat temperature. Thus the greater the K (proportional

gain) the higher the response speed of the valve. The proportional action

does not consider the superheat set point, but rather only reacts to

variations. Therefore if the superheat value does not vary significantly, the

valve will essentially remain stationary and the set point cannot be reached;

•

the integral action is linked to time and moves the valve in proportion to

the deviation of the superheat value from the set point. The greater the

deviations, the more intense the integral action; in addition, the lower

the value of T (integral time), the more intense the action will be. The

integration time, in summary, represents the intensity of the reaction of the

valve, especially when the superheat value is not near the set point;

•

the derivative action is linked to the speed of variation of the superheat value,

that is, the gradient at which the superheat changes from instant to instant.

It tends to react to any sudden variations, bringing forward the corrective

action, and its intensity depends on the value of the time T (derivative time).

Parameter/Description

Def.

Min.

Max.

UOM

CONTROL

Superheat set point

11

LowSH: thre-

shold

180 (324) K(°F)

PID: proportional gain

15

0

800

-

PID: integral time

150

0

1000

s

PID: derivative time

5

0

800

s

Tab. 5.b

See the “EEV system guide” +030220810 for further information on calibrating

PID control.

Note: when selecting the type of main control (both superheat control

and special modes), the PID control values suggested by CAREL will be

automatically set for each application.

P

rotection function control parameters

See the chapter on “Protectors”. Note that the protection thresholds are set by

the installer/manufacturer, while the times are automatically set based on the

PID control values suggested by CAREL for each application.

Parameter/Description

Def.

Min.

Max.

UOM

CONTROL

LowSH protection: threshold

5

-40 (-72)

SH set point

K (°F)

LowSH protection: integral time

15

0

800

s

LOP protection: threshold

-50

-60 (-76)

MOP: th-

reshold

°C (°F)

LOP protection: integral time

0

0

800

s

MOP protection: threshold

50

LOP: thre-

shold

200 (392)

°C (°F)

MOP protection: integral time

20

0

800

s

Tab. 5.c

5.3 Adaptive control and autotuning

Note: from the software revision following the 6.6-6.7, functions

“Adaptive control” and “Autotuning” are no longer present. Then

the setting:

Main control= air-conditioner/chiller or cabinet/ cold room with adaptive

control, is equivalent to:

Main control = multiplexed cabinet/cold room.

EVD evolution TWIN features two functions used to automatically optimise

the PID parameters for superheat control, useful in applications where there

are frequent variations in thermal load:

1.

automatic adaptive control: the function continuously evaluates the

effectiveness of superheat control and activates one or more optimisation

procedures accordingly;

2.

manual autotuning: this is activated by the user and involves just one

optimisation procedure.

Both procedures give new values to the PID superheat control and protection

function parameters:

-

PID: proportional gain;

-

PID: integral time;

-

PID: derivative time;

-

LowSH: low superheat integral time;

-

LOP: low evaporation temperature integral time;

-

MOP: high evaporation temperature integral time.

Given the highly variable dynamics of superheat control on different units,

applications and valves, the theories on stability that adaptive control and

autotuning are based on are not always definitive. As a consequence, the

following procedure is suggested, in which each successive step is performed

if the previous has not given a positive outcome:

1.

use the parameters recommended by CAREL to control the different

units based on the values available for the “Main control” parameter;

2.

use any parameters tested and calibrated manually based on laboratory

or field experiences with the unit in question;

3.

enable automatic adaptive control;

4.

activate one or more manual autotuning procedures with the unit in

stable operating conditions if adaptive control generates the “Adaptive

control ineffective” alarm.

A

daptive control

After having completed the commissioning procedure, to activate adaptive

control, set the parameter:

“Main control”= air-conditioner/chiller or showcase/cold room with adaptive

control

Parameter/Description

Def.

CONFIGURATION

Main control

multiplexed showcase/cold room

...

air-conditioner/chiller or showcase/cold

room with adaptive control

Tab. 5.d

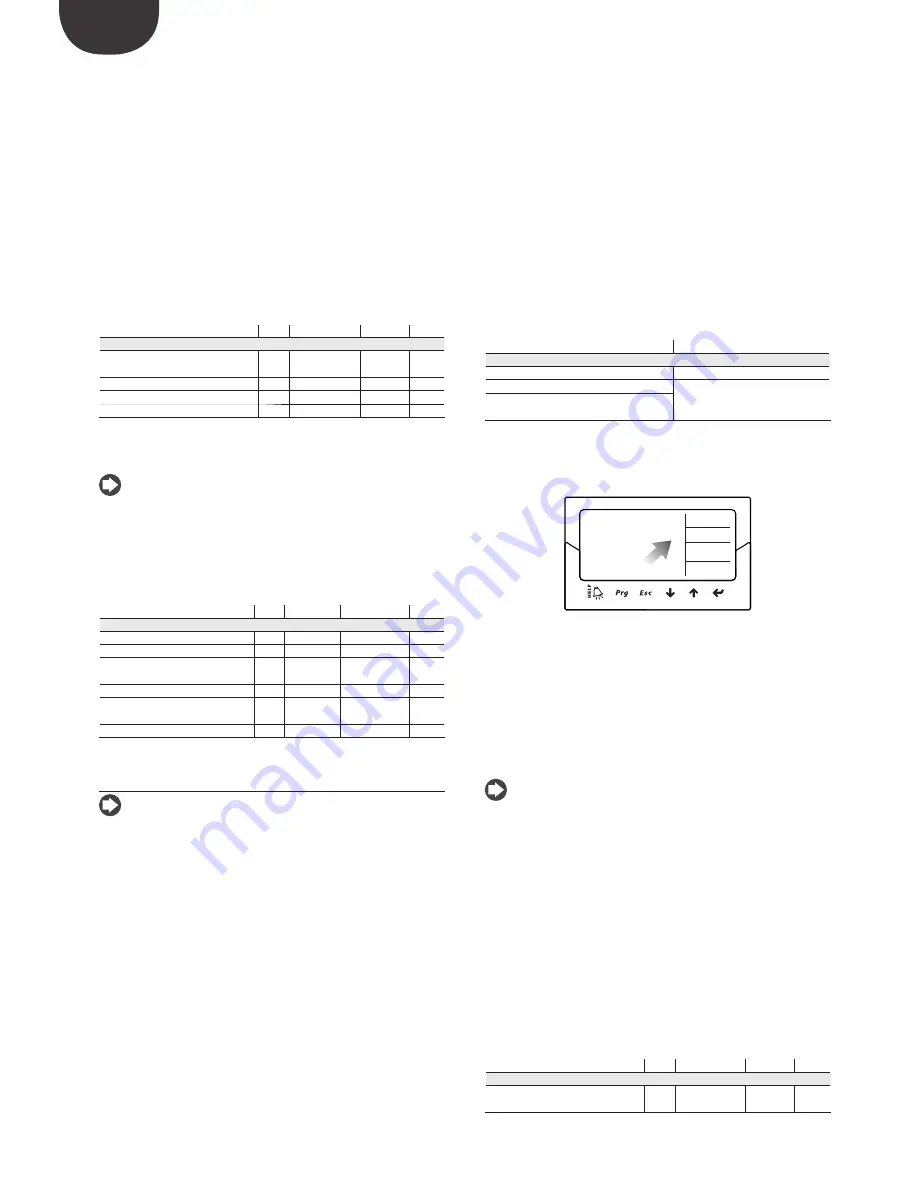

The activation status of the tuning procedure will be shown on the standard

display by the letter “T”.

Superheating

4.9 K

Valve opening

44 %

ON

-- Relais

A/B

T

Fig. 5.d

With adaptive control enabled, the controller constantly evaluates whether

control is sufficiently stable and reactive; otherwise the procedure for

optimising the PID parameters is activated. The activation status of the

optimisation function is indicated on the standard display by the message

“TUN” at the top right.

The PID parameter optimisation phase involves several operations on the

valve and readings of the control variables so as to calculate and validate

the PID parameters. These procedures are repeated to fine-tune superheat

control as much as possible, over a maximum of 12 hours.

Note:

•

during the optimisation phase maintenance of the superheat set point is

not guaranteed, however the safety of the unit is ensured through activation

of the protectors. If these are activated, the procedure is interrupted;

•

if all the attempts performed over 12 hours are unsuccessful, the “adaptive

control ineffective” alarm will be signalled and adaptive control will be

disabled, resetting the default values of the PID and protection function

parameters;

•

to deactivate the “adaptive control ineffective” alarm set the value of the

“main control” parameter to one of the first 10 options. If required, adaptive

control can be immediately re-enabled using the same parameter. If the

procedure ends successfully, the resulting control parameters will be

automatically saved.

A

utotuning

EVD evolution TWIN also features an automatic tuning function (Autotuning)

for the superheat and protector control parameters, which can be started by

setting the parameter “Force manual tuning” = 1.

Parameter/Description

Def.

Min.

Max.

UOM

SPECIAL

Force manual tuning

0 = no; 1= yes

0

0

1

-

Tab. 5.e

Summary of Contents for EVD Evolution Twin

Page 2: ......

Page 4: ......

Page 6: ......

Page 66: ...ENG EVD Evolution TWIN 0300006EN rel 2 6 31 01 2019 66 Note...

Page 67: ......